Multi-layered tunnel type tea infrared fragrance extracting machine

A technology of far-infrared and aroma machine, which is applied in the directions of tea spice, tea treatment before extraction, etc., can solve the problems of burning tea leaves, uneven heating of tea leaves, and retention of tea leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

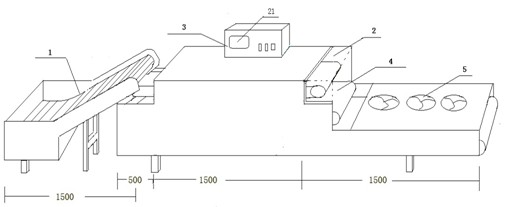

[0021] refer to Figure 1-6 , a multi-layer tunnel-type far-infrared tea aroma enhancing machine provided by the present invention is composed of an automatic non-broken uniform feeding system 1, an infrared emission system 2, an uninterrupted infrared irradiation precise temperature control system 3, and stepless speed regulation of multi-layer tea leaves Conveying system 4 and tea cooling system 5. Infrared emission system 2 and multi-layer tea conveying system 4 with stepless speed regulation are located in the tunnel box. Uninterrupted infrared irradiation and precise temperature control system 3 is placed above the tunnel box with temperature control. Table 21.

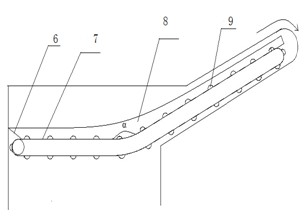

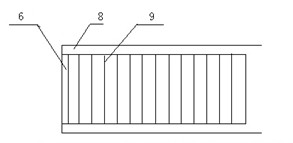

[0022] see figure 2 The automatic non-broken uniform feeding system 1 is composed of a food-grade material conveyor belt 7, a horizontal leak-proof tea edge protector 6, a longitudinal leak-proof tea edge protector 8, and a semi-cylindrical food-grade material scraping plate 9. The conveyor belt 7 is in the for...

Embodiment 2

[0027] Example 2 Actual Fragrant Operation

[0028] refer to Figure 1-6 , first turn on the main power supply of the uninterrupted infrared irradiation precise temperature control system 3, set the temperature required for aromatherapy, and then turn on the stepless speed-adjusting multi-layer tea delivery system 4 of the aromatherapy machine (adjust to fast and fast delivery first) ) and the power supply of the far-infrared emission system 2, when the temperature reaches the set value, pour the tea leaves into the automatic non-broken uniform feeding system 1, and turn on the speed control switch to adjust the feeding speed, and the tea leaves are exported through the upper end of the conveyor belt 7 Evenly send into the tunnel box, drop down on the first layer of conveyor belt 10 in the tunnel box to enhance the fragrance, when the tea reaches the end of the first layer of conveyor belt, it falls on the second layer of conveyor belt 11 in the opposite direction of movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com