Making method of raw tea for pure tea beverages

A technology for raw materials and beverages, applied in the direction of tea treatment before extraction, can solve the problems of increasing the complexity of the processing technology and increasing the cost, and achieve the effects of prolonging the stability and improving the dissolution rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing raw tea for pure tea beverage. The raw material used is Yingshuang variety (or H209 or H215 variety), and 50 kg of fresh tea leaves with a tenderness of 1 bud and 3 leaves to 1 bud and 4 leaves.

[0020] The specific implementation is as follows:

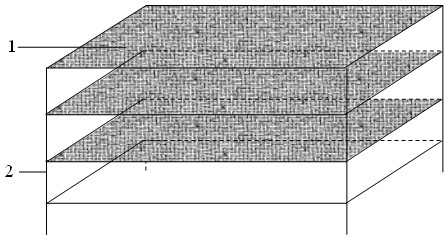

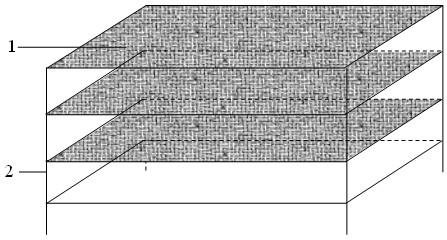

[0021] (1) Spread the fresh leaves on the three-dimensional green stand of stainless steel wire mesh, and then place the stand in a green stand with controllable temperature and humidity until the moisture content of the fresh leaves is about 70%; see figure 1 , the booth frame is made of stainless steel wire mesh 1 and stainless steel frame 2;

[0022] (2) Put green leaves treated in step (1) on the hot air cleaning machine (6CSF-500 high temperature hot air cleaning machine produced by Zhejiang Shangyang Machinery Co., Ltd.) Control 900rpm, control the amount of leaf input at 200kg / h), the moisture content of the green leaves is about 50%, and cool the green leaves on the cooling leaf storage tank (p...

Embodiment 2

[0032] Taking the traditional roasted green sample as a control (traditional roasted greens are done by drum, the moisture content of the finished leaves is controlled at about 55-60%, the kneading is processed by cold kneading, and then directly dried twice), the raw tea obtained is the same steeping method. The extraction process and flavor quality analysis methods after storage were used to compare the differences in TP extraction amount and quality stability of the two teas. See Table 1 and Table 2 for the results. It can be seen from Table 1 and Table 2 that ① compared with the traditional baked green tea samples, the tea soup made from the special raw material tea for pure tea beverages is improved by introducing new processes such as hot air drying, hot kneading, in-process crushing, and far-infrared aroma enhancement. The quality stability was significantly better than that of the control, and the decrease in sensory score of the prepared tea soup was reduced by 48.5% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com