Tobacco flavor extraction method

An extraction method and tobacco technology, applied in the directions of tobacco, separation method, tobacco treatment, etc., can solve the problems of organic solvent residue, large difference in taste, overheating and scorching of raw materials, etc., so as to alleviate the dry distillation conditions, ensure the aroma quality, and avoid scorching. Muddy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

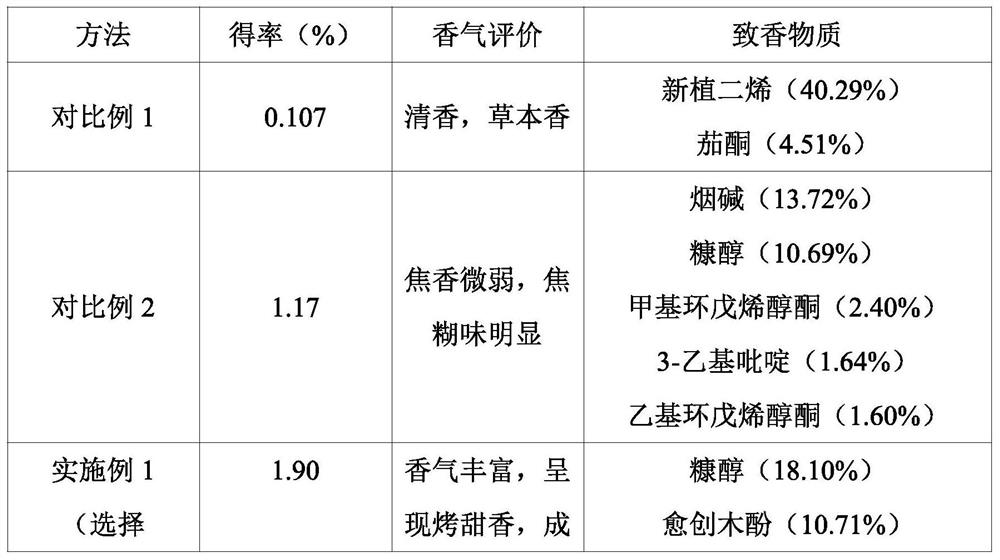

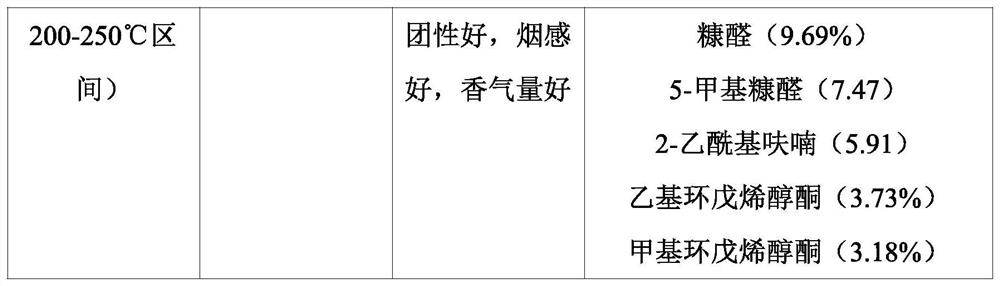

[0035] Example 1 Superheated Steam Distillation-Dry Distillation Integrated Technology Extraction of Tobacco Flavor

[0036]Turn on the multifunctional steam distillation-cory distillation integrated equipment according to the above method, respectively set the steam generation device, superheated steam device, and steam distillation-cory distillation device to 200°C, 480°C, and 80°C (external heating mantle temperature), and put them into the device. Nitrogen gas was introduced, and the nitrogen flow rate was 80 mL / min. When the internal temperature of the steam distillation-carbonization device rose to 60°C, the water cooling system was turned on, and 400g of tobacco raw material (flue-cured tobacco leaf fragments, 10 mesh, the same below) was added into the steam distillation-carbonization device. The water vapor passes from the steam generating device to the superheated steam device at a rate of 5600mL / min, and then to the steam distillation-carbonization device after rehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com