Technology and equipment for integrating essence and spice extraction and micro-capsule preparation

A technology of flavors and fragrances and microencapsulation, which is applied in the directions of microcapsule preparations, essential oils/flavors, and microsphere preparation, etc., can solve the problems of small research team, no reports of enlargement and industrialization, etc. The effect of applying the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

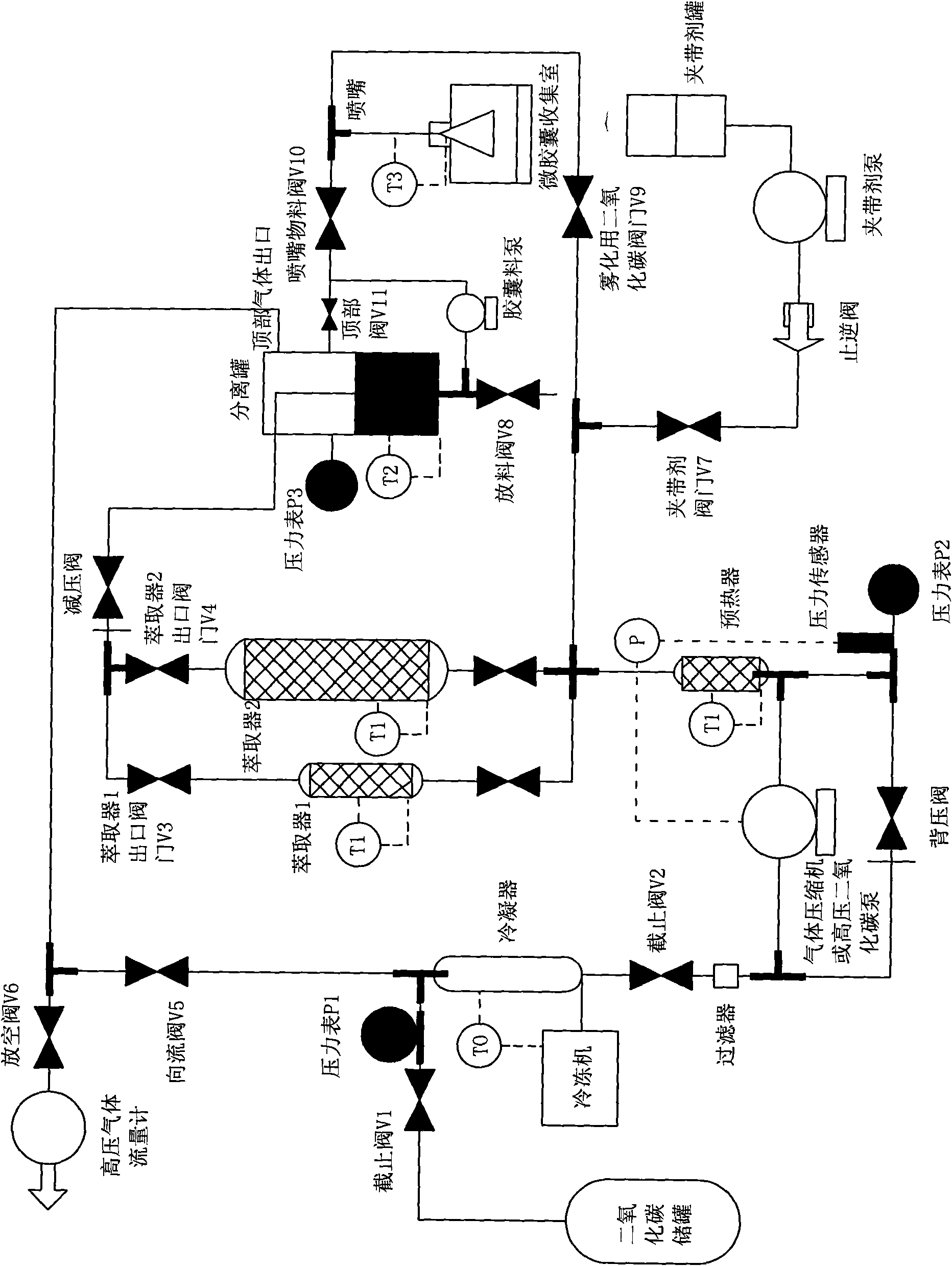

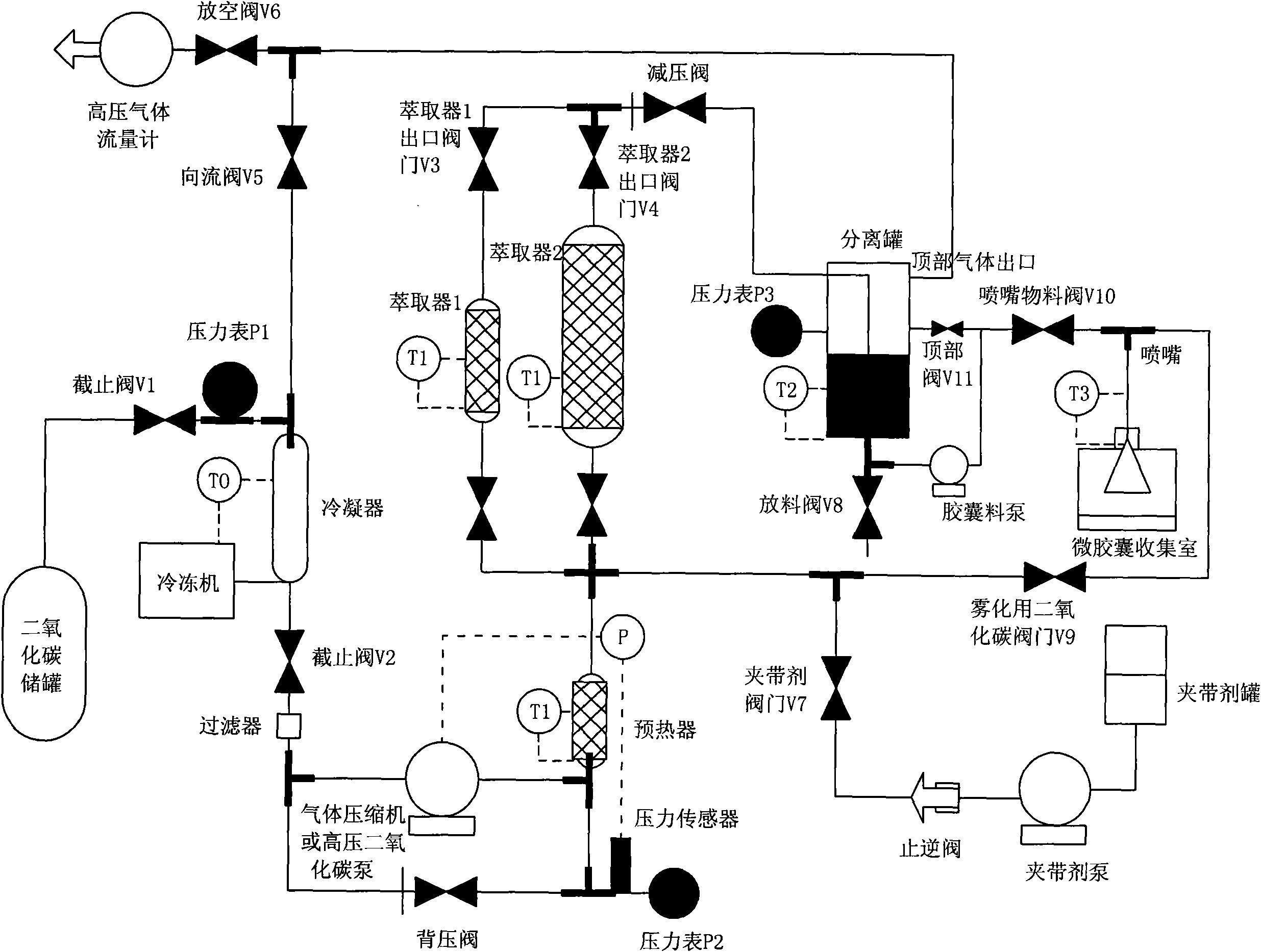

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: tea fragrance palmitic acid microcapsules

[0032] Check the air tightness of the device, the heating and heat preservation of each channel, and the display and control of the instrument. After confirming that there is no problem, set the temperature of the condenser to -5-5°C, the preheating temperature to 60°C, the extraction temperature to 60°C, and the separation tank The temperature is 60°C, the microencapsulation pre-expansion temperature is 60°C, the extraction pressure is 30MPa, the separation tank pressure is 6MPa and the microencapsulation pre-expansion pressure is 10MPa. Load Tieguanyin tea 500g into extractor 2 (the front and rear valves of extractor 2 are closed), and pack palmitic acid 100g into the separation tank.

[0033] As mentioned above, open the carbon dioxide storage tank and shut-off valves V1 and V2, and press liquid carbon dioxide into the preheater with a high-pressure carbon dioxide pump. Adjust the back pressure valve to reach...

Embodiment 2

[0035] Embodiment 2: the silicon dioxide microcapsule of phenethyl alcohol

[0036] Check the air tightness of the device, the heating and heat preservation of each channel, and the display and control of the instrument. After confirming that there is no problem, set the condenser temperature to -5-5°C, the preheating temperature to 50°C, the extraction temperature to 50°C, and the separation tank The temperature is 50°C, the extraction pressure is 20MPa, and the separation tank pressure is 20MPa. In the extractor 1 (the front and rear valves of the extractor 1 are closed), 50 ml of phenylethyl alcohol are loaded, and 100 g of silicon dioxide with an average particle diameter of 10 μm is loaded into the separation tank.

[0037] As mentioned above, open the carbon dioxide storage tank and shut-off valves V1 and V2, and press liquid carbon dioxide into the preheater with a high-pressure carbon dioxide pump. Adjust the back pressure valve to reach the control pressure of 20MPa....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com