Preparation method of super-hydrophobic antimony sulfide coating

A water antimony sulfide and antimony sulfide technology, which is applied in the field of preparation of superhydrophobic antimony sulfide coatings, can solve the problems of no superhydrophobic antimony sulfide coatings, lower photoelectric conversion efficiency, troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of embodiment 1 superhydrophobic antimony sulfide coating, comprises the steps:

[0024] Weigh 0.5mmol of antimony trichloride and 2mmol of thiosemicarbazide and dissolve it in 30mL of ethylene glycol (EG) solvent, place the solution in a long-necked flask, and react for 15 minutes at a microwave intensity of 800W. After the product obtained was centrifugally washed to remove the residual solvent, it was then ultrasonically dispersed in 15 mL of absolute ethanol, and the dispersion was completely spread on an ordinary glass sheet, and rotated at a speed of 4000 rpm for 30 seconds to make the obtained antimony sulfide product uniform Scattered on the substrate, repeated 10 times to prepare antimony sulfide coating. Finally, soak the coating in 10mmol / L stearic acid ethanol solution for 60 minutes, take it out and dry it at 120°C for 2 hours to obtain the superhydrophobic antimony sulfide coating.

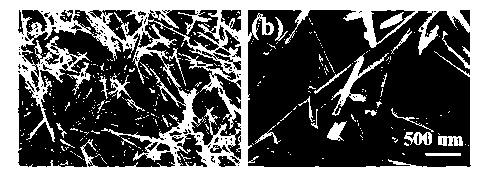

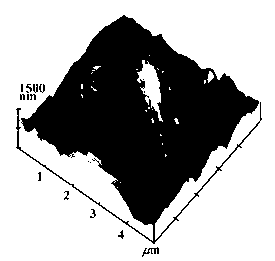

[0025] figure 1 It is the SEM picture of the ant...

Embodiment 2

[0029] The preparation method of embodiment 2 superhydrophobic antimony sulfide coatings, comprises the steps:

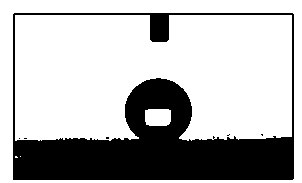

[0030] Weigh 1mmoL of antimony trichloride and 1mmol of thiosemicarbazide and dissolve them in 15mL of diethylene glycol (DEG) solvent, place the solution in a long-necked flask, and react for 10 minutes at a microwave intensity of 800W. After the product obtained was centrifugally washed to remove the residual solvent, it was then ultrasonically dispersed in 15 mL of absolute ethanol, and the dispersion was completely spread on the ITO sheet, and rotated for 30 seconds at a speed of 2000 rpm, so that the obtained antimony sulfide product was evenly dispersed On the substrate, the antimony sulfide coating was obtained by repeating 30 times. Finally, soak the coating in 50mmol / L stearic acid ethanol solution for 30 minutes, take it out and dry it at 100°C for 6h to obtain the superhydrophobic antimony sulfide coating. The water contact angle of the coating surface o...

Embodiment 3

[0031] The preparation method of embodiment 3 superhydrophobic antimony sulfide coatings, comprises the steps:

[0032] Weigh 1.5mmol of antimony trichloride and 4mmol of sodium thiosulfate and dissolve in 50mL of triethylene glycol (TEG) solvent, place the solution in a long-necked flask, and react for 30 minutes at a microwave intensity of 800W. After the product obtained was centrifugally washed to remove the residual solvent, it was then ultrasonically dispersed in 20 mL of absolute ethanol, and the dispersion was completely spread on the FTO sheet, and rotated for 30 seconds at a speed of 5000 rpm, so that the obtained antimony sulfide product was evenly dispersed On the substrate, the antimony sulfide coating was obtained by repeating 30 times. Finally, soak the coating in 1 mmol / L ethanol stearic acid solution for 120 minutes, take it out and dry it at 80°C for 8 hours to obtain the superhydrophobic antimony sulfide coating. The water contact angle of the coating surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com