Wheat impurity removing device for agricultural machinery

An agricultural machinery and wheat technology, applied in the agricultural field, can solve the problems of short maturity period and high labor intensity of wheat, and achieve the effects of avoiding impurity removal failure, improving efficiency and avoiding clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

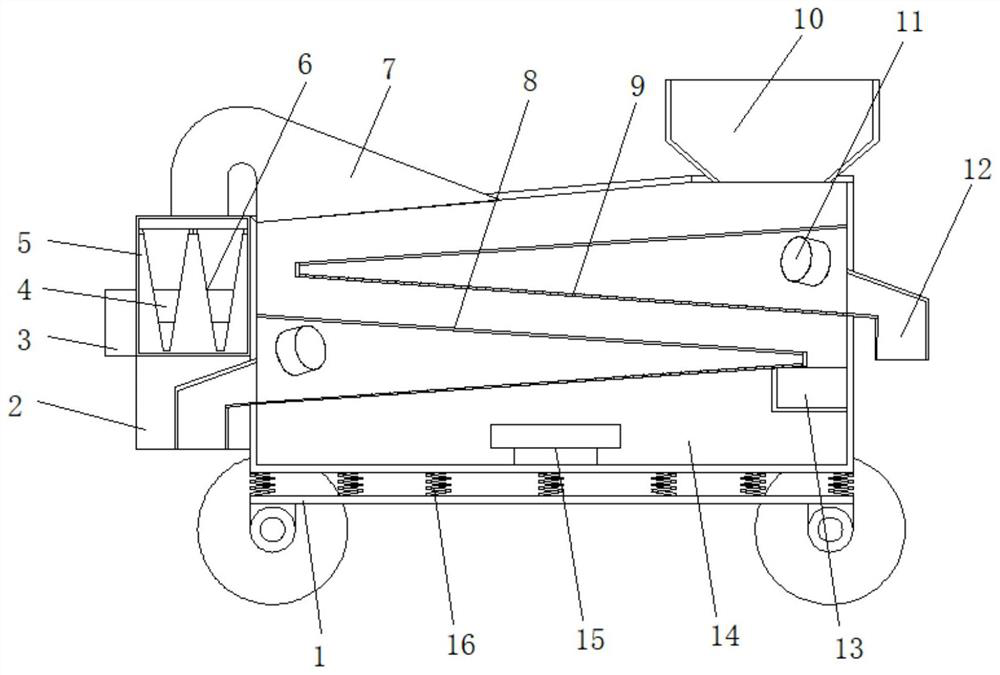

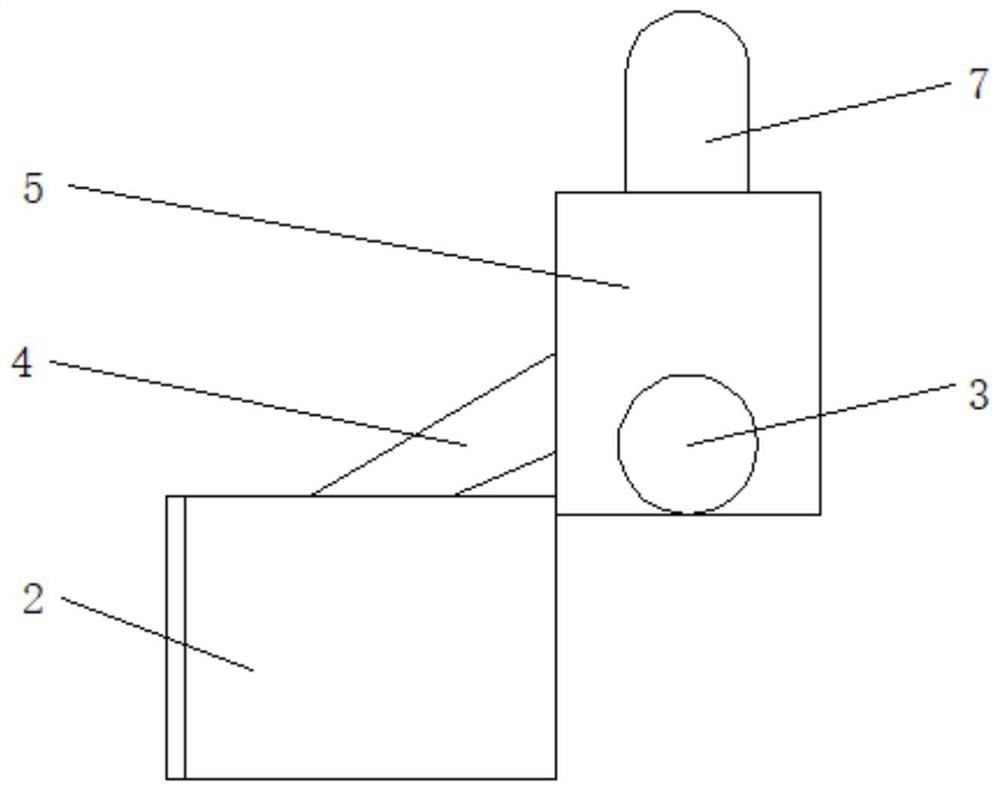

[0027] refer to Figure 1-4 , a wheat impurity removal device for agricultural machinery, comprising a base 1, a plurality of springs 16 are fixedly installed on the top of the base 1, and a box body 14 is fixedly installed between the top ends of the springs 16, and an advanced spring is fixedly installed on the top of the box body 14. Material box 10, and the side of box body 14 is fixedly installed with discharge pipe 13, and the inside of box body 14 is fixedly installed with a plurality of staggered screen boards 8 and support plates 9, and the screen plates 8 and support plates 9 The ends are distributed in a V-shaped structure, and the two ends of the box body 14 are respectively fixedly equipped with miscellaneous discharge pipes 12 adapted to the ends of the support plate 9, and the bottom end of the box body 14 is fixedly installed with a vibration motor 15, and the box body Both sides of 14 are fixedly installed with two blowers 11, and the air outlet of the blower ...

Embodiment 2

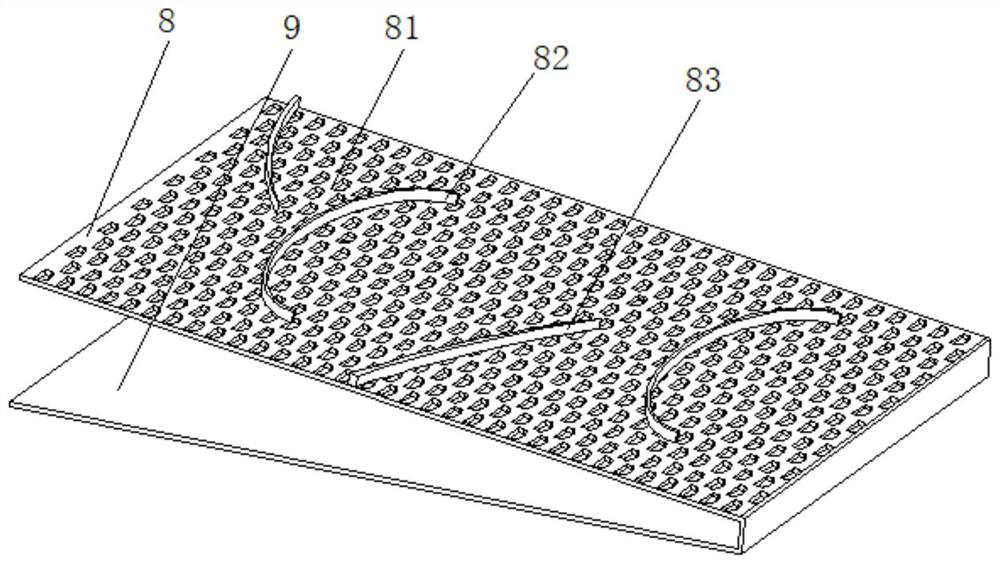

[0036] refer to Figure 1-5 , a wheat impurity removal device for agricultural machinery. Compared with Embodiment 1, the top of the screen plate 8 is fixedly equipped with a plurality of arc-shaped baffle plates 84. When the wheat slides on the top of the screen plate 8 When the wheat is subjected to vibration and crosses the baffle plate 84, a height drop will be generated to aggravate the vibration, which improves the screening effect of wheat seed gravel and improves the removal effect of bran and dust.

[0037] The top of the baffle plate 84 is an arc-shaped structure, and the top of the baffle plate 84 is provided with a plurality of V-shaped grooves 85. When the wheat passes through the grooves 85, a staggered height difference will be produced to further increase the vibration of the wheat. , to speed up the removal efficiency.

[0038] When the present embodiment is in use, when the wheat slips on the top of the sieve plate 8, when the wheat is subjected to vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com