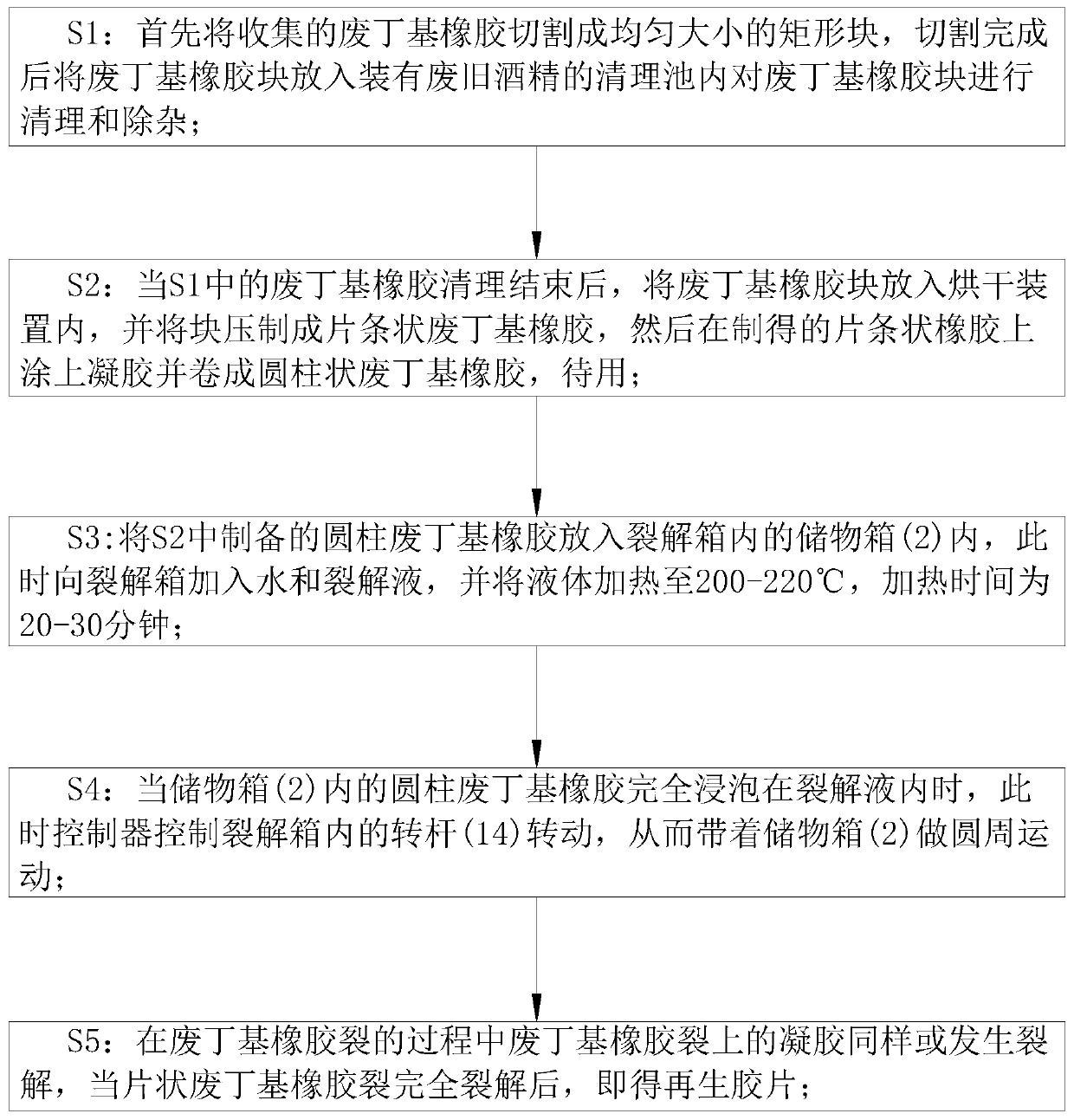

Cracking process of waste butyl rubber

A waste butyl rubber and process technology, applied in the field of waste butyl rubber cracking process, can solve the problems of precipitation and accumulation, air and water pollution, waste butyl rubber accumulation, etc., and achieve the effect of improving the degree of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

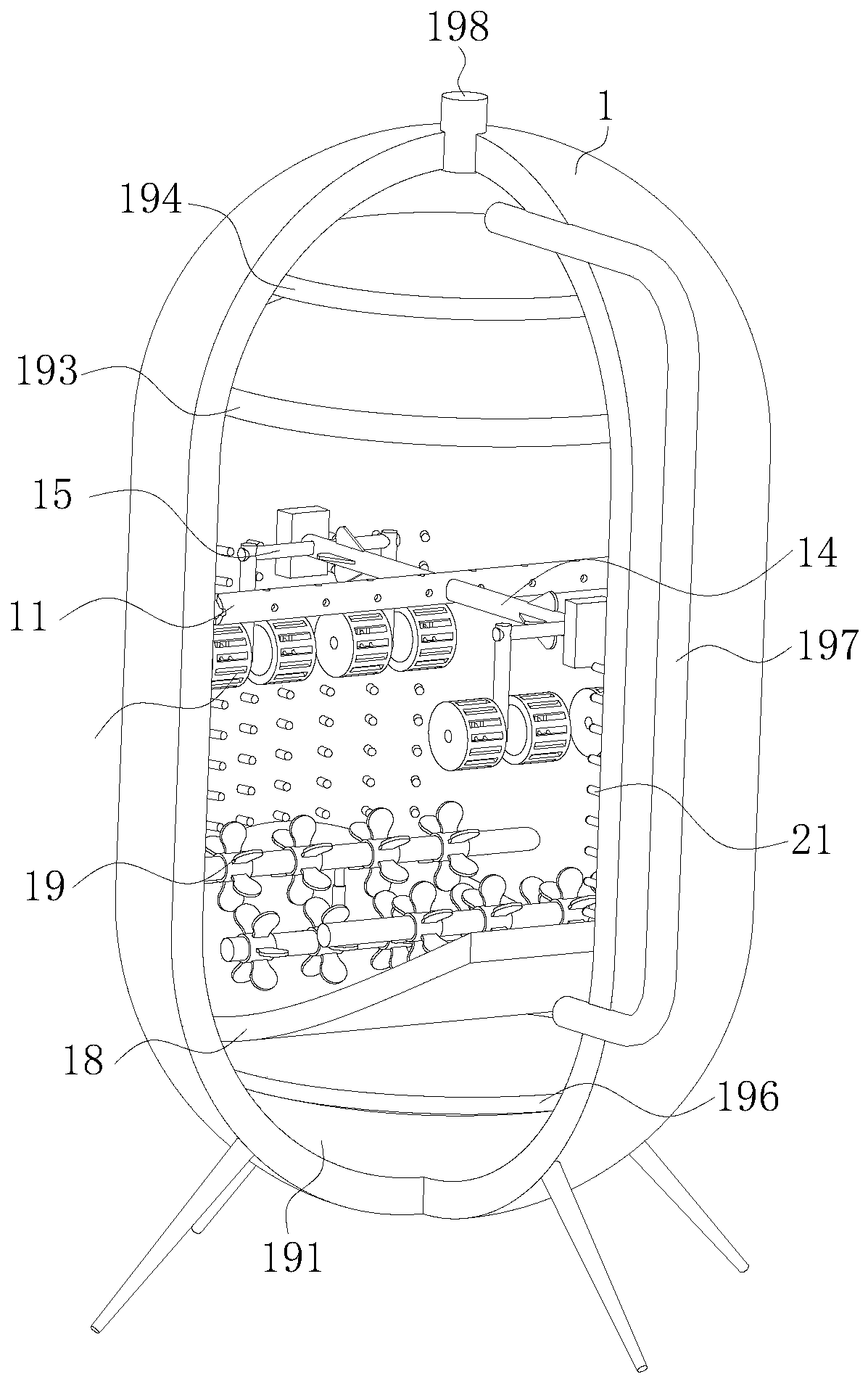

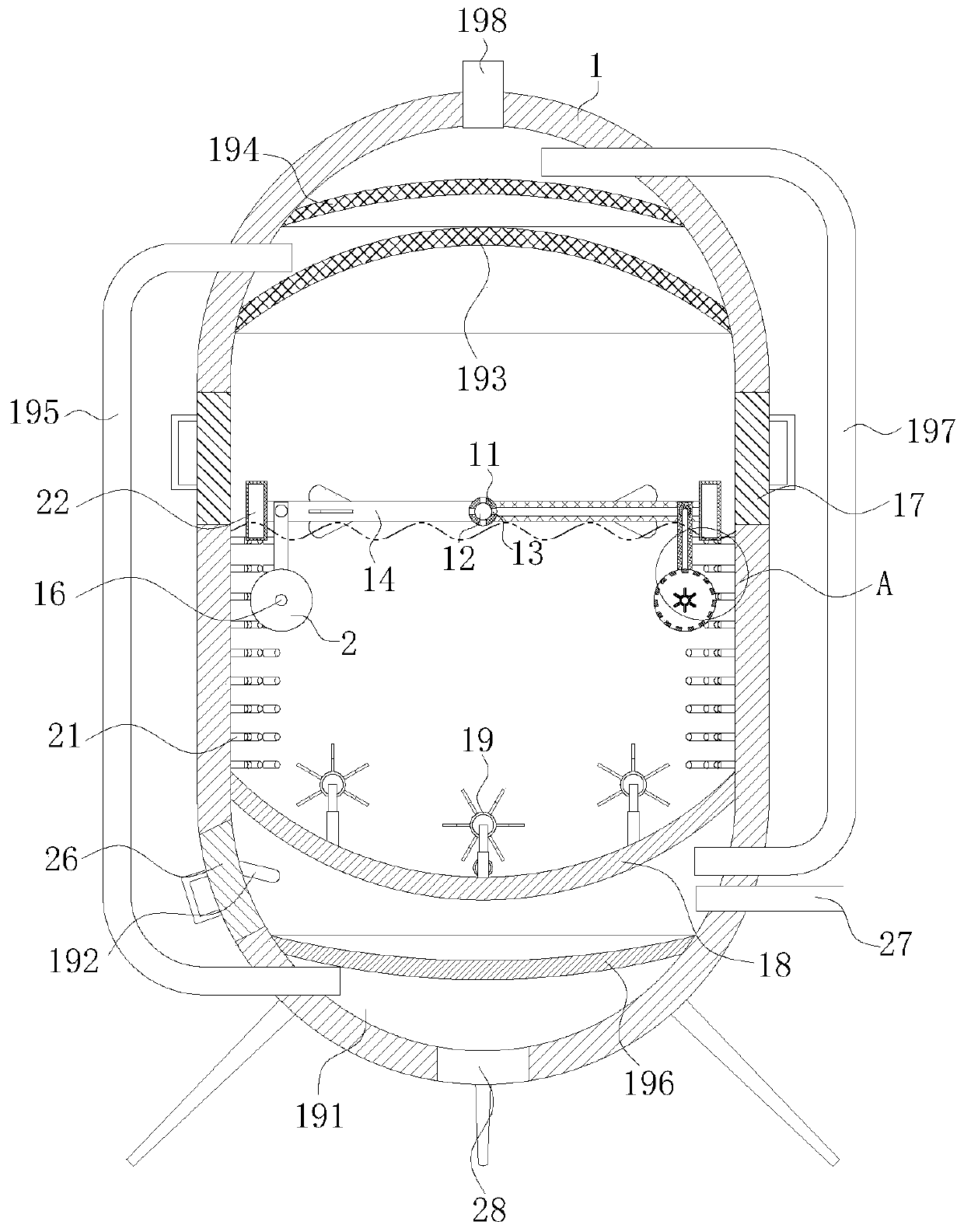

[0051] As an embodiment of the present invention, a second filter layer 194 is fixedly connected to the inner wall of the box body 1 above the first filter layer 193, and a second conduit 197 is placed above the second filter layer 194; Activated carbon is filled above the filter layer 194;

[0052] During operation, since the second conduit 197 extends to the top of the second filter layer 194, the gas after combustion can flow into the top of the second filter layer 194 through the second conduit 197, and in this process, the gas after combustion and the gas generated can be prevented from recombination. contact, thereby causing the gas to be toxic again, because activated carbon is arranged above the second filter layer 194, which can absorb impurities and particles in the burned gas, thereby preventing the gas from flowing into the air and causing pollution.

[0053] The specific workflow is as follows:

[0054] During work, when using the cracking box that the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com