Screen printing method and device thereof

A screen printing device and screen printing technology, applied in the direction of screen printing machine, printing, printing machine, etc., can solve the problems of reducing filling and unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

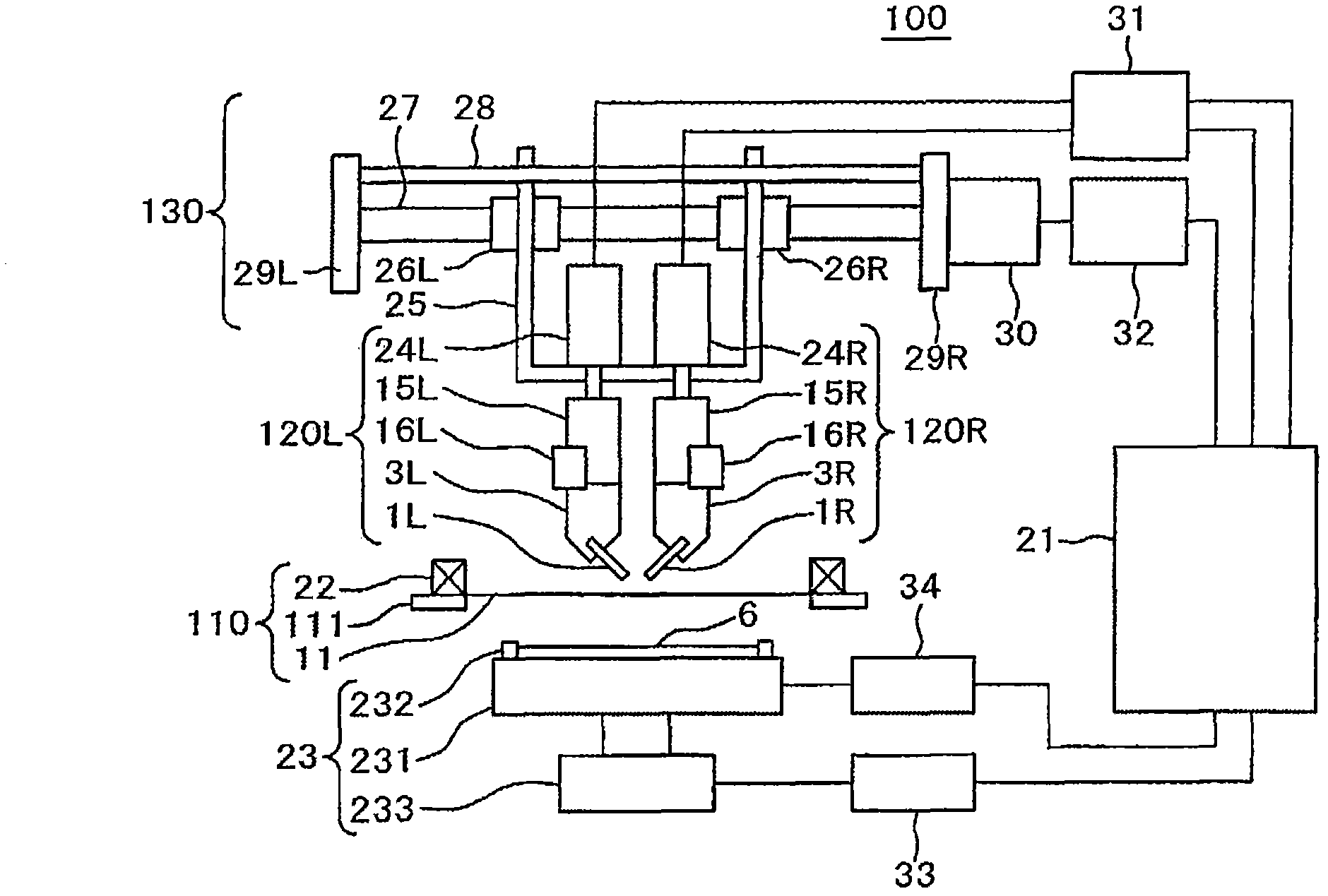

[0097] use figure 1 The configuration of the printing apparatus 100 of the first embodiment will be described. figure 1 It is a front view of the printing apparatus 100 of the first embodiment. For simplification purposes, figure 1 In , the representation of the frame, side walls, pillars, supporting members, etc. of the device is omitted.

[0098] The printing apparatus 100 has a printing mask unit 110 , a printed object support table unit 23 , a pair of squeegee units 120L and 120R, a squeegee drive mechanism unit 130 , and a control unit 21 .

[0099] The printing mask portion 110 is configured to have: a metal mask 11 provided with a pattern opening corresponding to a desired circuit pattern of the object to be printed (for example, a printed wiring board) 6; The frame 22, which is rectangular in plan view, is held in a tensioned state; and the supporting member 111 that supports the frame. The printed object supporting table unit 23 has a table 231 on which the printe...

Embodiment 2

[0146] This second embodiment is the same as the above-mentioned first embodiment except that a screen mask is used for the printing mask 11 .

[0147] In Embodiment 2, a mesh screen is used for the printing mask 11 . As the mesh, a #325 flat-woven mesh using a high-strength wire with a wire diameter of 16 μm and a yarn thickness of 35 μm was used. As this mesh, a mesh mask of pattern openings with a diameter of 50 μm to 200 μm formed by emulsions having a thickness of 35 μm and a thickness of 55 μm was used.

[0148] In order to release the printing mask 11 and the object 6 using the screen tension, the tension of the printing mask is 0.2 mm or less (measured with a tension gauge STG-80NA manufactured by PROTEK Corporation).

[0149] The metal mesh used for the printing mask 11 used in the second embodiment has an opening ratio of 40% or more, and the wire diameter for the metal mesh needs to be smaller than half of the opening width of the metal mesh.

[0150] In the patte...

Embodiment 3

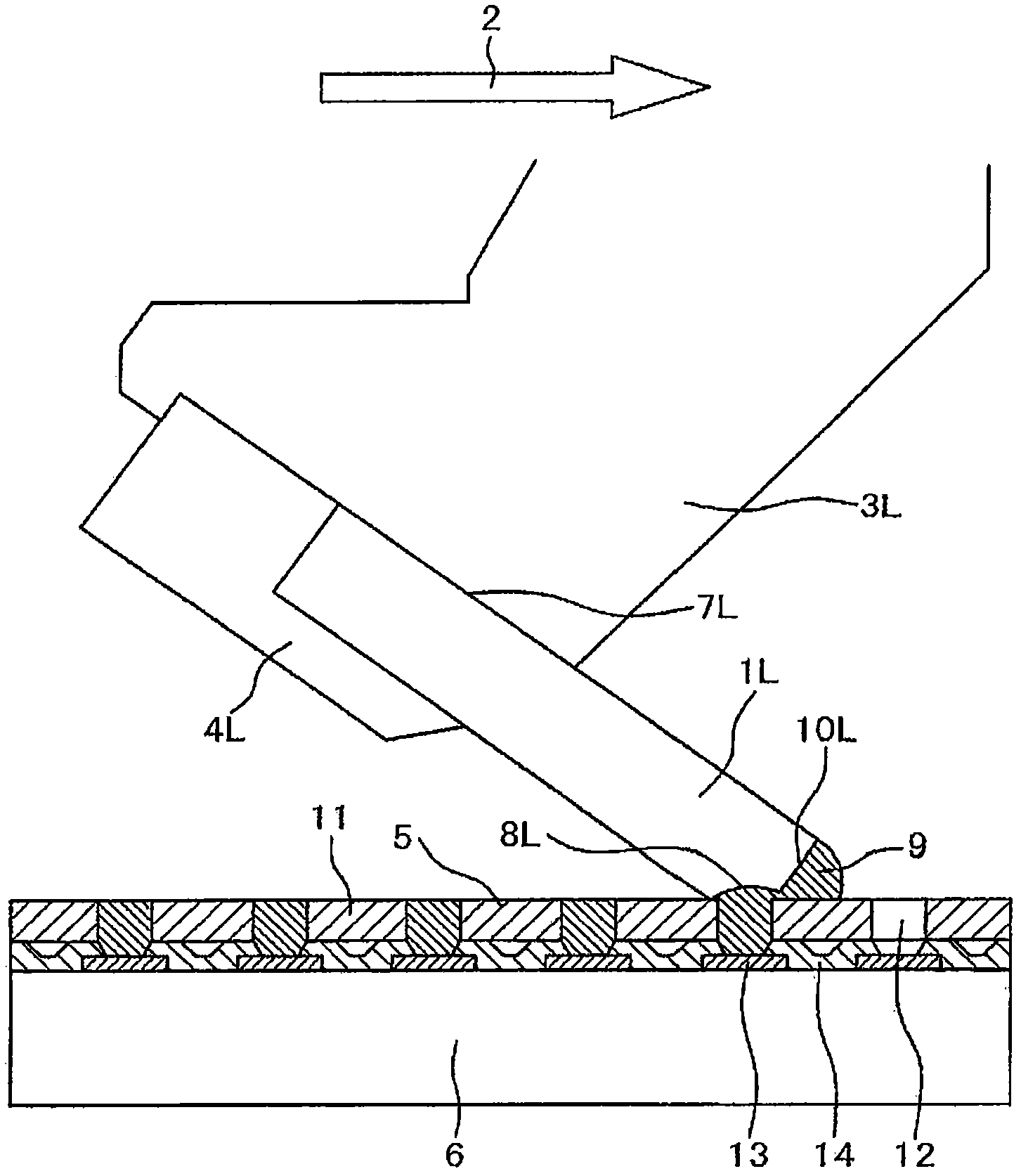

[0160] use Figure 7 The structure of the squeegee mounted on the printing device of the third embodiment will be described. The squeegee used in Example 3 is a flat squeegee, and is a squeegee 71 in which a glass epoxy resin plate 727 is inserted into the center of the squeegee as a support.

[0161] A schematic diagram of the tip shape of the scraper 71 used in the third embodiment is as follows: Figure 8 shown. exist Figure 8 In the figure, in order to explain the shape of the tip of the squeegee 71, an enlarged view of the main part of the squeegee structure is shown by taking a flat squeegee as an example.

[0162] In the third embodiment, the installation direction of the squeegee 71 is set in the opposite direction to that of the first embodiment, and the squeegee 71 is inclined in the same direction as the printing direction 2 . Except that the shape of the scraper 71 is changed, it is the same as that of the first embodiment described above. Since the compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com