Multilayer spherical container damper

A technology of dampers and containers, applied in springs/shock absorbers, engines, wind power generation, etc., can solve the problems of dissipating vibration energy and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

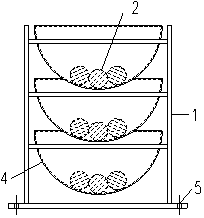

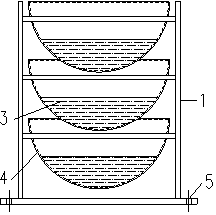

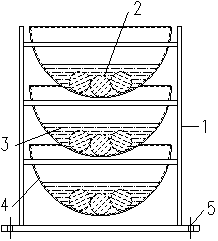

[0017] Embodiment 1: The present invention is a multi-layer spherical container damper suitable for wind power generation towers. In actual use, first determine the placement position of the damper according to the available space inside the cabin and platform, so as to determine the choice Figure 1~Figure 4 The damper type shown. The dynamic characteristics of the wind power tower to be installed with dampers are tested to determine its first-order natural frequency. Since the damping effect is the best when the natural frequency of the damper is almost equal to the first-order natural frequency of the wind power tower, the rolling frequency of the rolling ball or the oscillation frequency of the liquid in the damper is determined accordingly. According to the expected vibration reduction effect, when the rolling ball or liquid mass is taken as 1.5%~2.5% of the first-order modal mass of the wind power tower, the vibration reduction effect can reach 20%~30%. In order to ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com