Device applicable to rotational welding of three parts

A technology of spin welding and welding head, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of unsatisfactory workpiece shape, deviation of workpiece size, inaccurate manual positioning, etc., to achieve good welding effect and welding. Precise, efficient welding results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the drawings, but the protection scope of the present invention is not limited to the following.

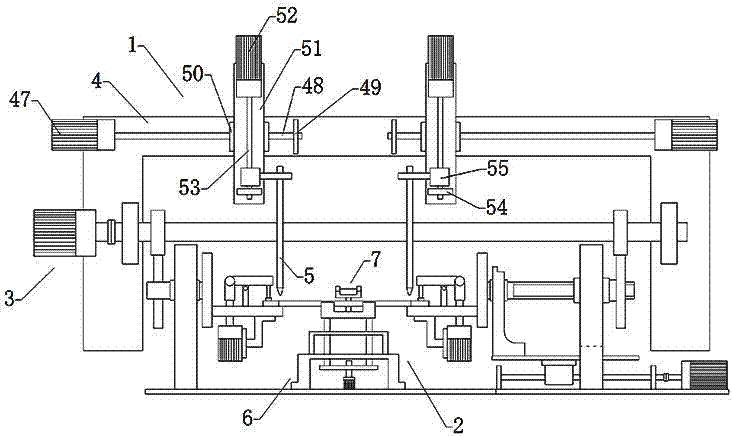

[0021] Such as Figure 1 ~ Figure 6 As shown, a device suitable for three-piece spin welding includes a gantry welding mechanism 1, a positioning mechanism 2, and a synchronous rotation mechanism 3.

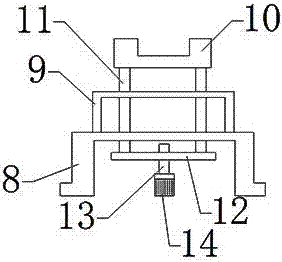

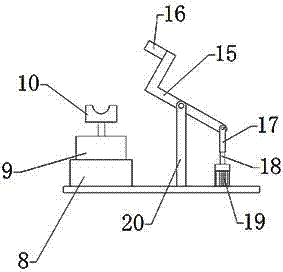

[0022] Such as Figure 1 ~ Figure 3 As shown, the gantry welding mechanism 1 includes a gantry 4 and a welding head 5. The welding head 5 is arranged at the beam position of the gantry 4, and a synchronous rotation mechanism 3 is fixed on the column of the gantry 4, and the middle of the synchronous rotation mechanism 3 The position is provided with a positioning mechanism 2. The positioning mechanism 2 includes a supporting mechanism 6 and a pressing mechanism 7. The supporting mechanism 6 includes a door-shaped support frame A8 and a door-shaped support frame B9. The door-shaped support frame B9 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com