Rotor type compressor

A compressor and rotor-type technology, applied in the field of rotor-type compressors, can solve problems such as thermal deformation, eccentric clearance effects, internal leakage, etc., and achieve the effects of reducing components, ensuring coaxiality, and ensuring clearances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

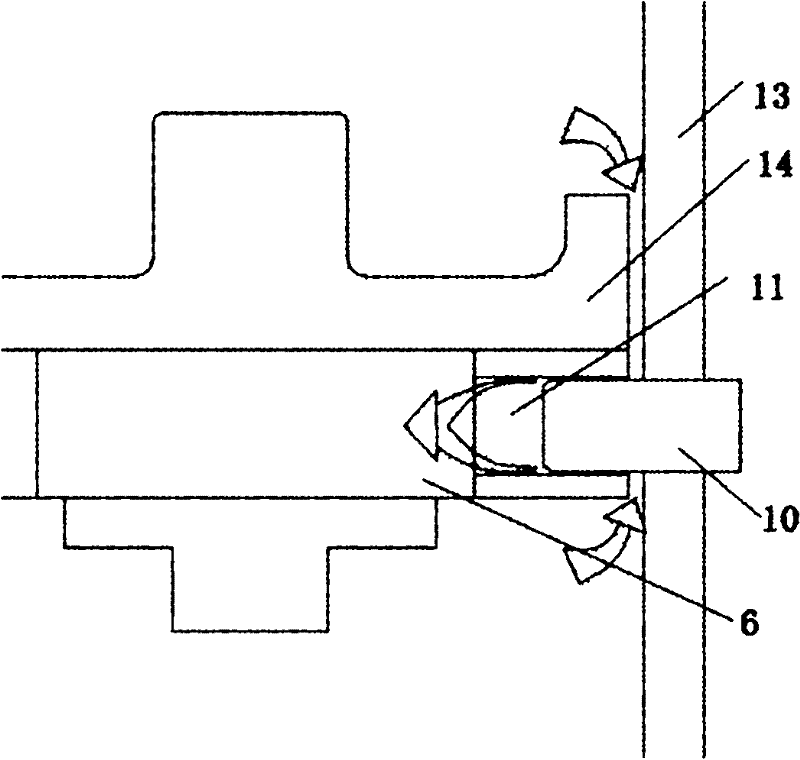

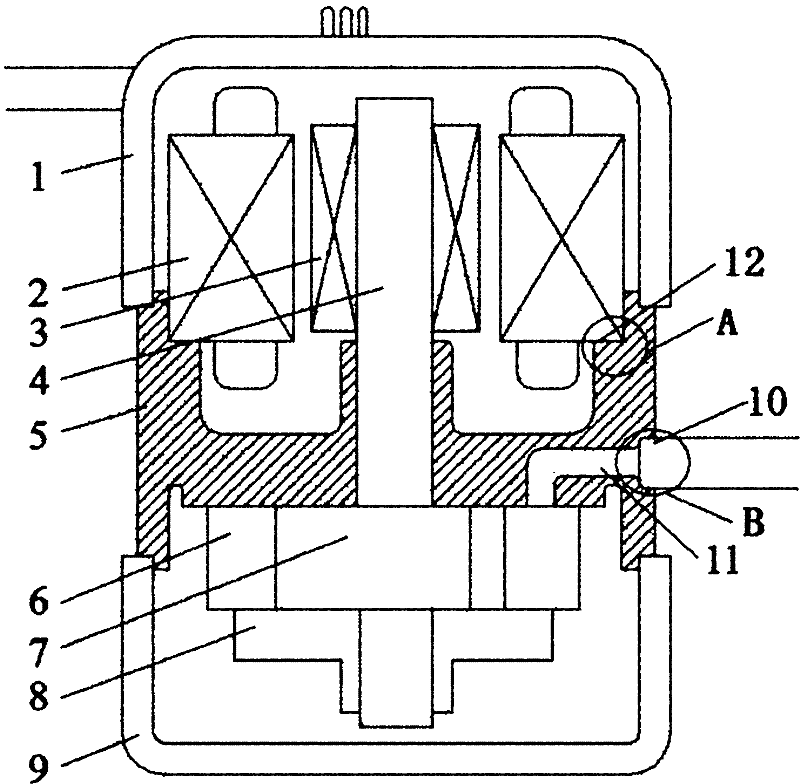

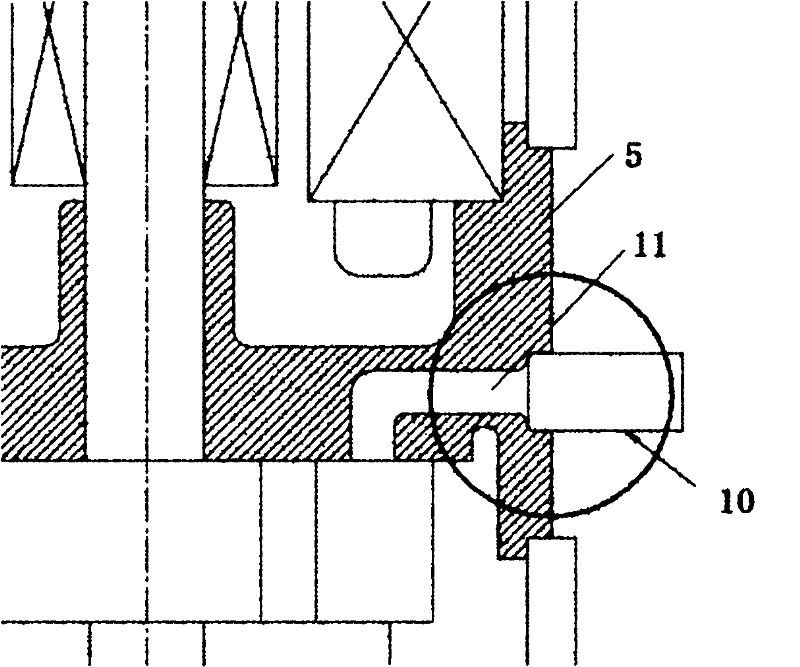

[0030] Such as Figure 1-2 As shown in the figure, the DC variable frequency rotary compressor using environmentally friendly refrigerant includes an upper casing cover 1, a stator 2, a rotor 3, a crankshaft 4, an upper cylinder head and a casing combined into one, and a one-piece frame 5 , cylinder 6, piston 7, lower cylinder head 8, lower shell cover 9, intake connecting pipe 10, integrated frame 5 is made of metal material, such as cast iron (FC250) by casting one-time molding. The upper part of the integrated frame 5 is connected and fixed with the upper case cover 1 by laser welding, and the lower part is connected and fixed with the lower case cover 9, as figure 1 As shown in A, the top of the integrated frame 5 is provided with an inner concave platform, and the inner concave platform is provided with an inner concave platform plane 12, and the lower end of the stator 2 is fixedly connected to the inner concave platform plane 12 by bolts. The stator is installed on thi...

Embodiment 2

[0035] see Figure 1-2 As shown, a rotor compressor, wherein the stator is directly connected to the stepped plane on the inner concave platform plane 12 of the integrated frame 5 through bolts. The top of the integrated frame 5 is connected and fixed with the upper shell cover 1 by glue, and its bottom is connected and fixed with the lower shell cover 9 with glue, and all the other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com