Acoustic wave transducer

An acoustic transducer and transducer technology, applied in seismology for well logging records, etc., can solve the problem of fragmentation of transmitting crystals, small elastic deformation of apron 8, unfavorable routing of receiving transducer 5 and Assembly and other issues, to achieve the effect of increasing the amount of elastic deformation, reducing the amount of overall deformation, and facilitating wiring and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

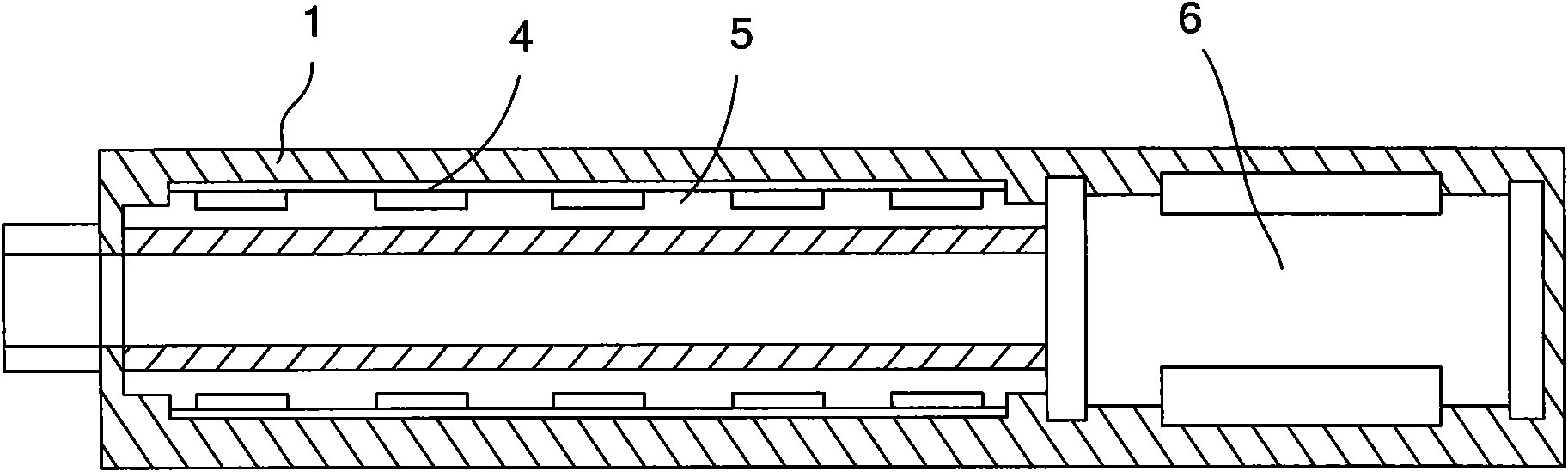

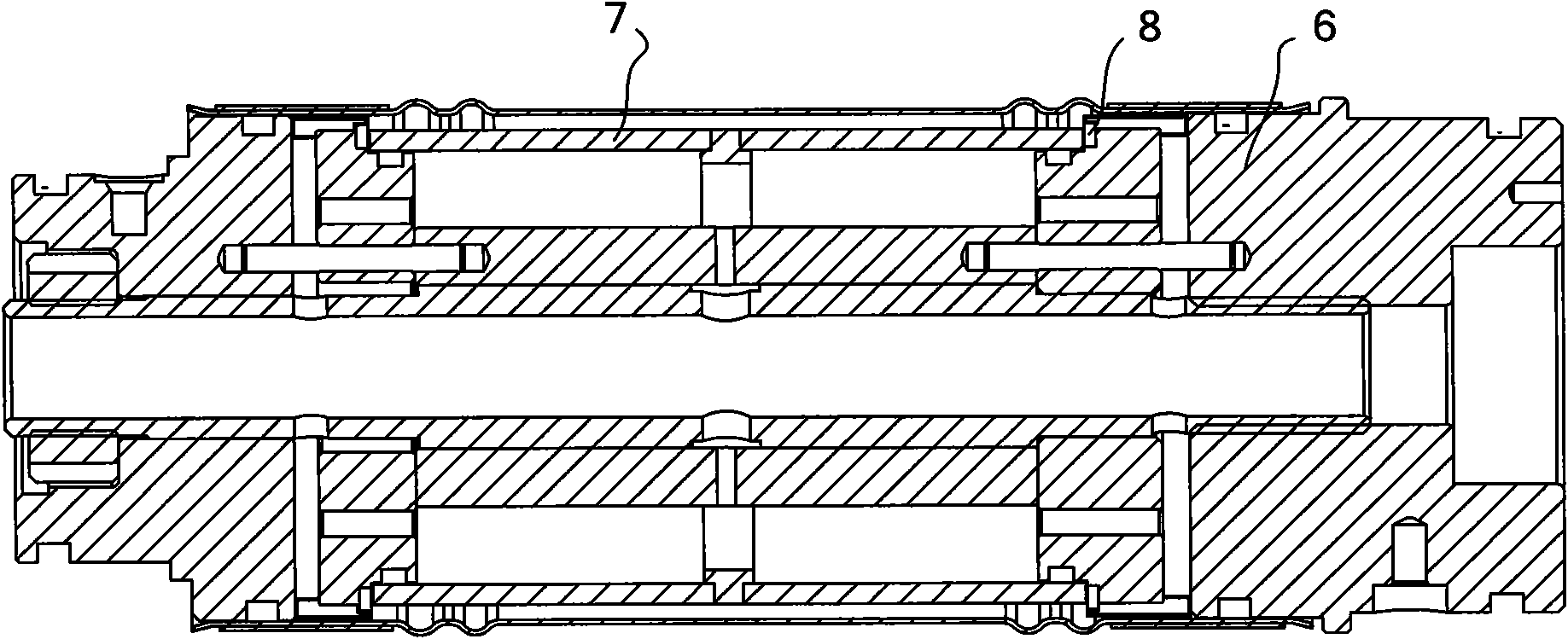

[0032] Such as Figure 4 As shown, the present invention includes a slotted housing 1, a receiving transducer module 2, a transmitting transducer 3, and a bladder 4. The slotted shell 1 is a shell of the present invention. In order to improve the sound insulation effect of the slotted shell 1, a plurality of slot holes 11 are provided on the slotted shell 1.

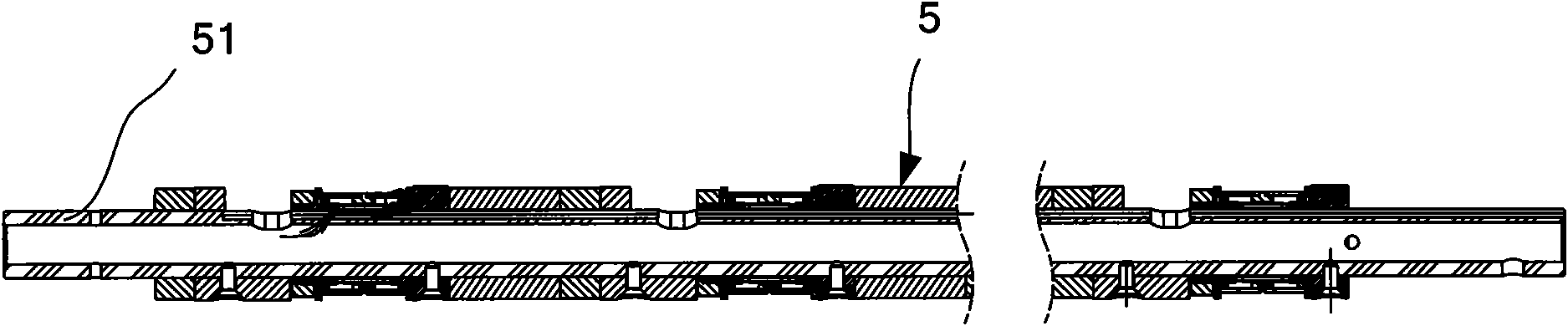

[0033] The receiving transducer module 2 is set in the slotted housing 1 for receiving signals. The receiving transducer module 2 includes two or more receiving transducers 21, which are connected in series by threads.

[0034] The transmitting transducer 3 is arranged on the side of the receiving transducer module 2 and is nested in the slotted housing 1 like the receiving transducer module 2. One end of the transmitting transducer 3 is fixedly connected with the slotted housing 1, and the other end is a free end.

[0035] The bladder 4 is a flexible piece, and is set in the slotted shell 1 to wrap and receive the transducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com