Machining method for stator of all-metal screw pump for thickened-oil thermal exploitation

A pump stator and all-metal technology, which is applied in the processing field of all-metal screw pump stators for heavy oil heat, can solve the problems of long workpiece length, easy aging, peeling, and difficult processing of spiral grooves in the inner hole of the stator, etc., to ensure accuracy, The effect of improving machining accuracy and reducing machining difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

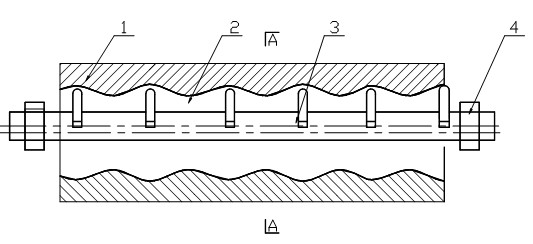

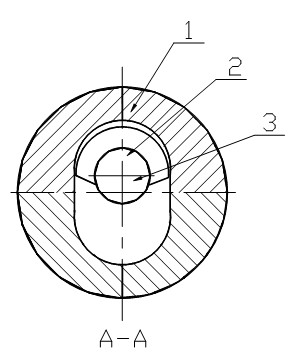

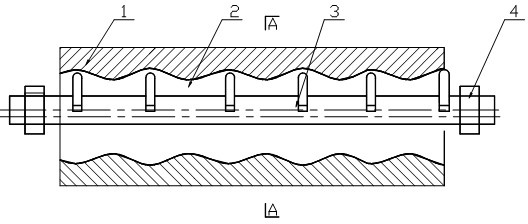

[0016] exist figure 1 , 2 , the metal stator bar (1) with a central hole penetrates into the steel pipe (3) with the electrode (2) installed, and its two ends are clamped by the left chuck (4) and the right chuck (5) And pull tight to one or both sides. The workbench of the EDM machine moves in a straight line, and the metal stator bar (1) with a central hole does a helical movement, and a strict transmission ratio is ensured between the two, that is, the workpiece rotates one circle, and the workbench walks a pitch. (2) The quantity is determined according to the number of pitches. Therefore, the workpiece can be rotated one circle, the workbench can move one pitch, and the processing of the spiral groove is completed once. The steel pipe (3) and the electrode (2) reciprocate, and the diameter To feed, gradually complete the machining process. The machining of one pitch by each electrode can simultaneously complete the overall machining of the inner spiral groove of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com