Combined clamp for rack upright post pressure test

A pressure test and shelf column technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inaccurate description of column performance, different end structures or sizes, column test pieces cannot be hinged, etc., to reduce work intensity , Improve efficiency and improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

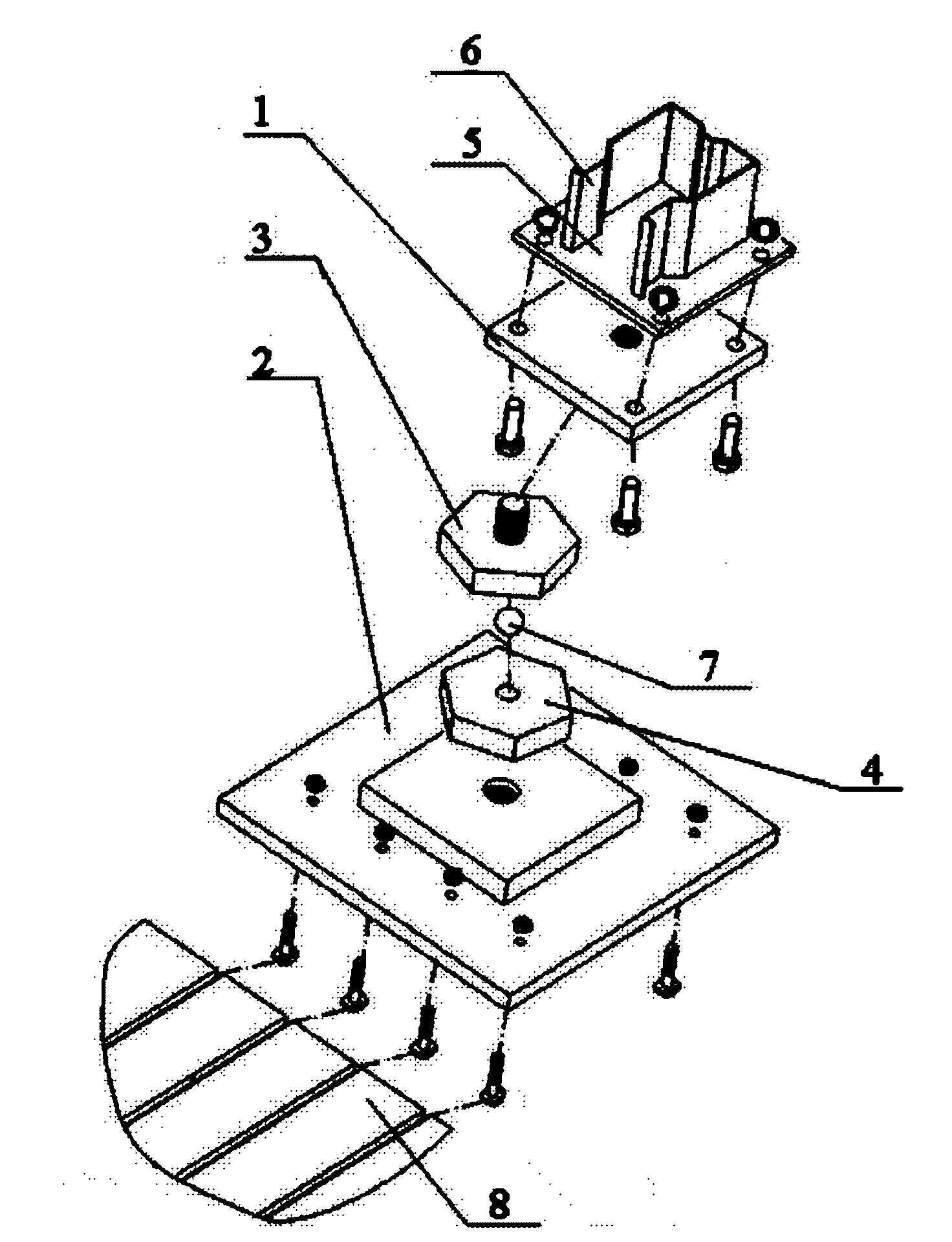

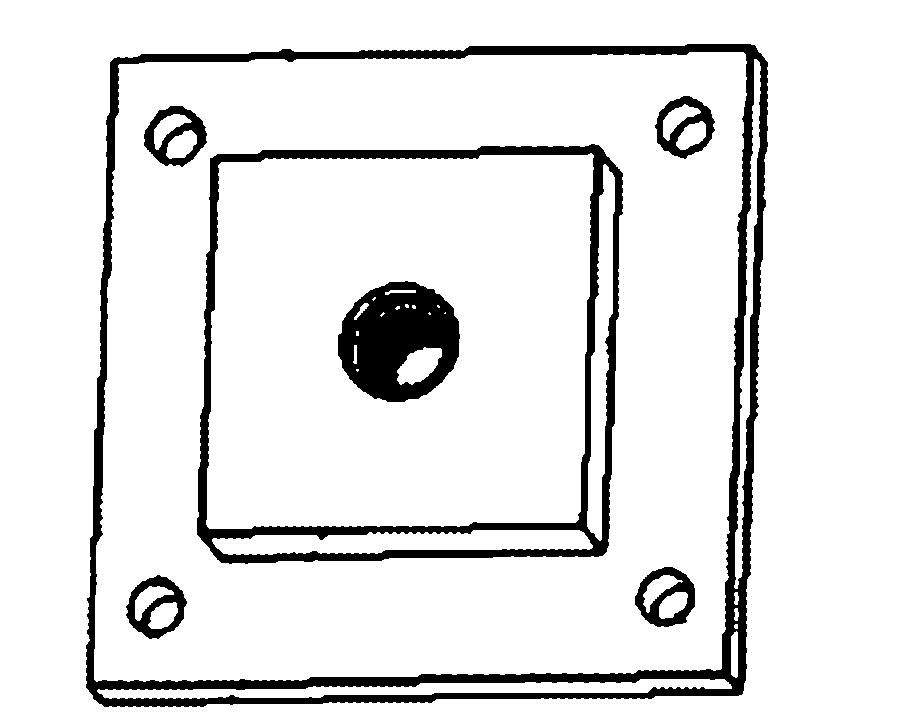

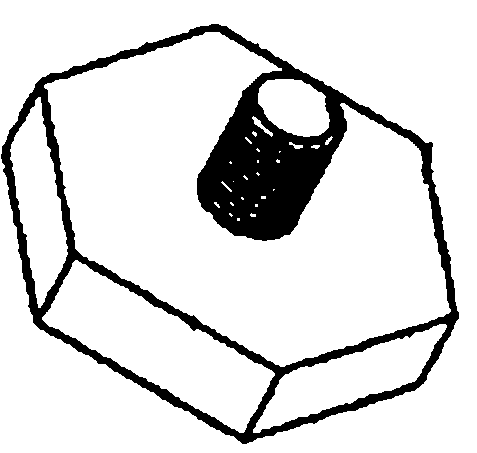

[0022] Embodiment 1: This embodiment relates to a combination fixture used for a shelf column pressure test, such as figure 1 As shown, the column fixing plate 1 is connected with the column bottom plate 5 welded with the column 6 by 4 hex bolts through the bolt holes on the 4 column fixing plates 1 . Such as figure 2 , image 3 with Figure 4 As shown, the middle part of one side of the upper steel ball clamping block 3 has a threaded column, and the middle part of the other side is provided with a spherical groove. The middle part of the boss of the column fixing plate 1 has a threaded hole that runs through the whole. Align the threaded hole in the center of the column fixing plate 1 and screw it in to fix it. The workbench fixing plate 2 is placed on the T-slot workbench 8 of the press, and fixed on the T-slot workbench 8 through the 8 bolt holes on the workbench fixation plate 2 with 8 T-bolts. The bolt can move along the T-shaped slot to adjust the position of the w...

Embodiment 2

[0023] Embodiment 2: This embodiment also relates to a combination fixture used for a shelf column pressure test, its structure is roughly the same as that of Embodiment 1, the difference is that, as Image 6 with Figure 7 As shown, the structure of the upper and lower steel ball clamping blocks in this embodiment is that the middle part of one side is provided with threaded columns, and the middle part of the other side is provided with bosses, and the bosses of the upper and lower steel ball clamping blocks are all provided with threaded columns. Features spherical grooves. By adding a boss on one side of the steel ball clamping block, the fixture can be applied to steel balls with a smaller diameter, thereby avoiding collisions when the steel ball clamping block rotates around the steel ball. The method of installing the steel ball clamp described in Embodiment 1 is also applicable to the method of installing the steel ball clamp in this embodiment. When replacing the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com