OCR laminating machine internal height measurement assembly and height measurement method

A technology for laminating machines and components, applied in the field of mechanical processing, can solve problems such as cracking and instability, and achieve the effect of simple and easy way and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

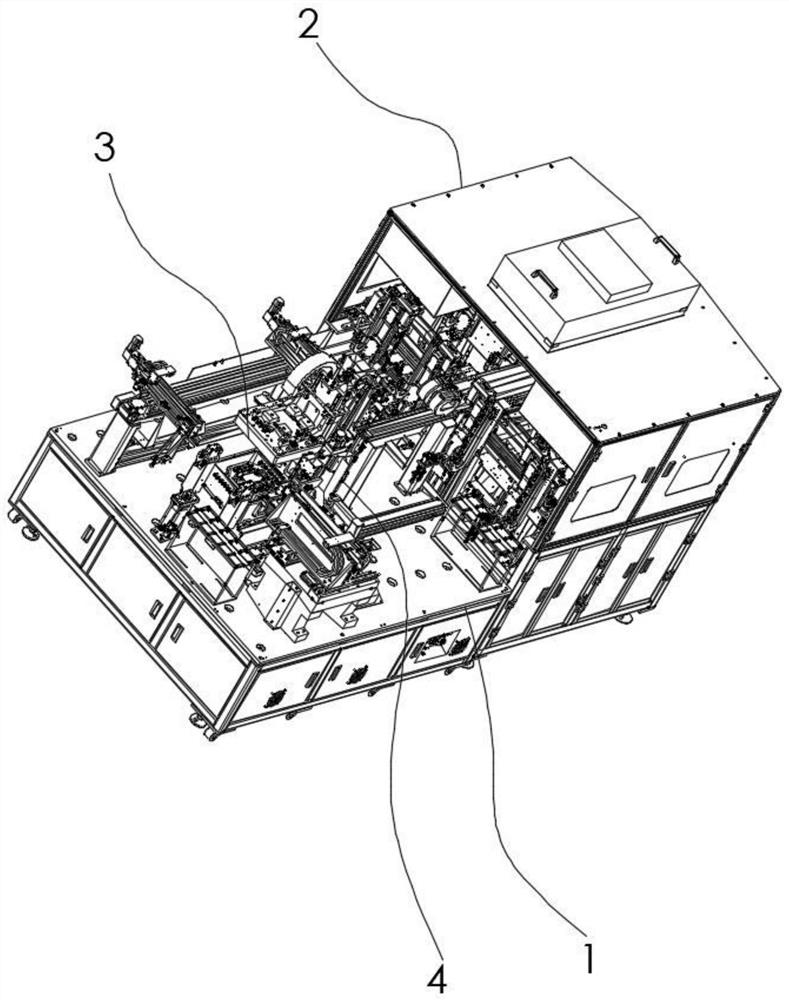

[0038] refer to Figure 1 to Figure 5 , an internal height measuring component 4 of an OCR laminating machine and a height measuring method, comprising a frame body 1 and a loading and unloading frame 2 arranged on one side of the frame body 1, the frame body 1 is provided with a bonding component 3, One side of the bonding component 3 is provided with a height measuring component 4,

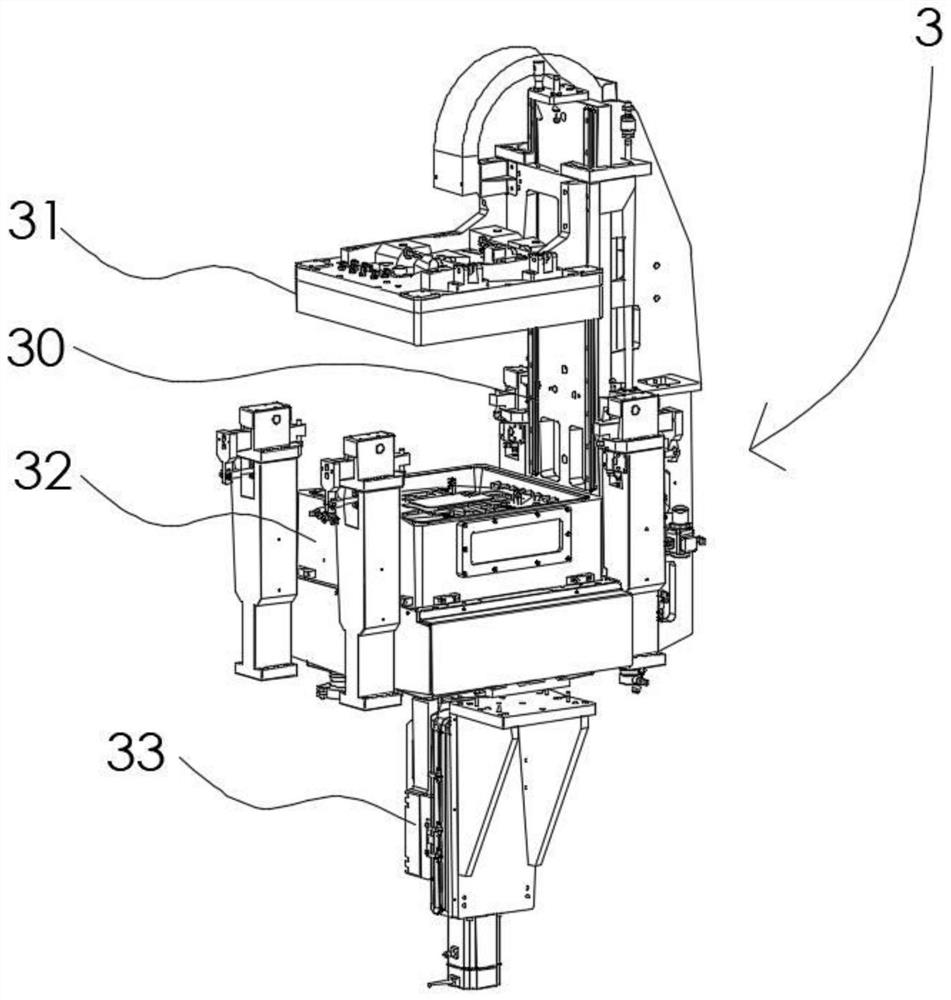

[0039] The bonding assembly 3 includes a slide rail 30 and a top carrier 31 movably connected above the slide rail 30 , a bottom carrier 32 is movably connected below the slide rail 30 , and a lifting device 33 is connected to the bottom of the bottom carrier 32 .

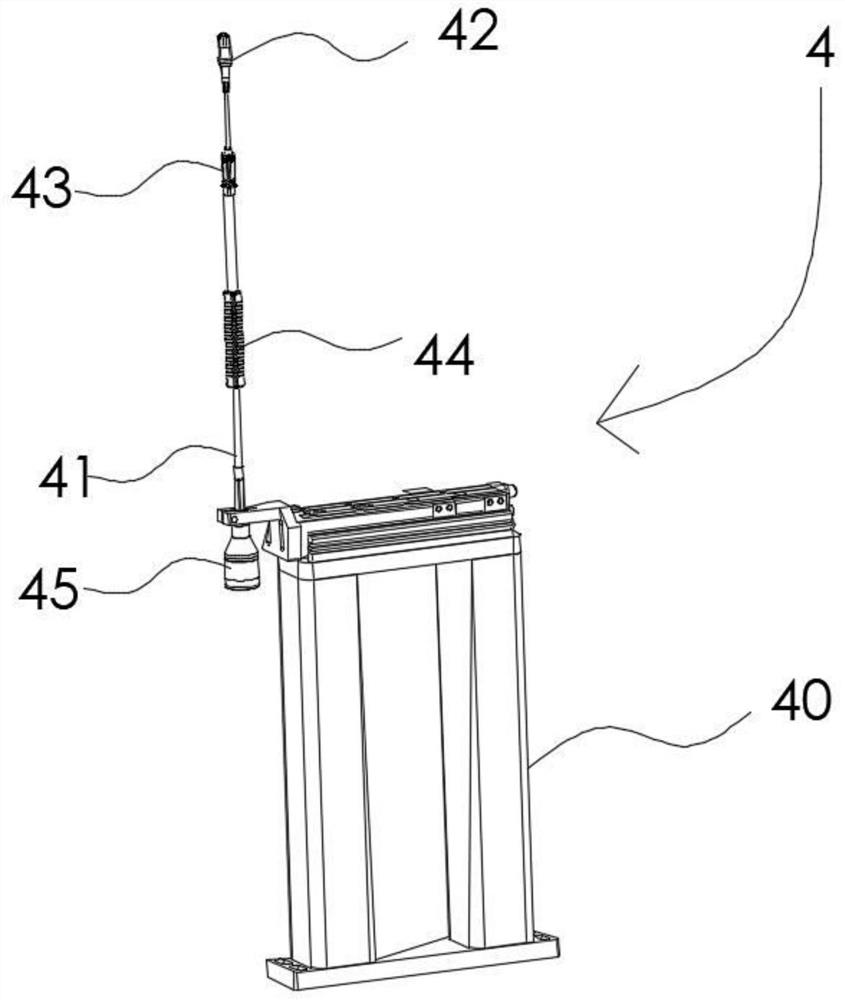

[0040] The height measuring assembly 4 comprises a support rod 41 installed on the bottom mounting base 40; a first induction device 42 arranged at the upper end of the support rod 41; a second induction device 43 arranged below the first induction device 42; a third induction device 44 below the device 43,

[0041] And the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com