Motor rotor

A technology of motor rotor and rotor iron core, applied in electrical components, electromechanical devices, electric components, etc., can solve the problem of small contact surface between permanent magnet and rotor iron core, difficulty in matching between magnetic steel and rotor iron core, affecting motor stability and Safety and other issues, to achieve the effect of saving labor costs, low costs, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

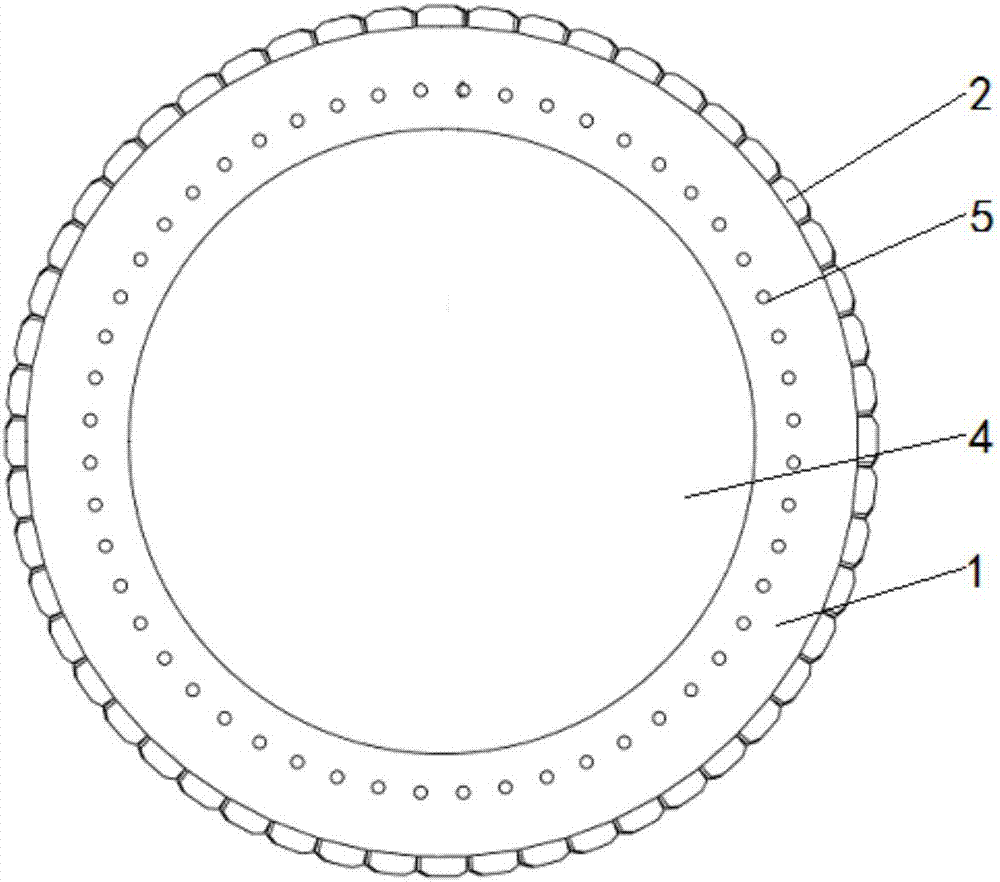

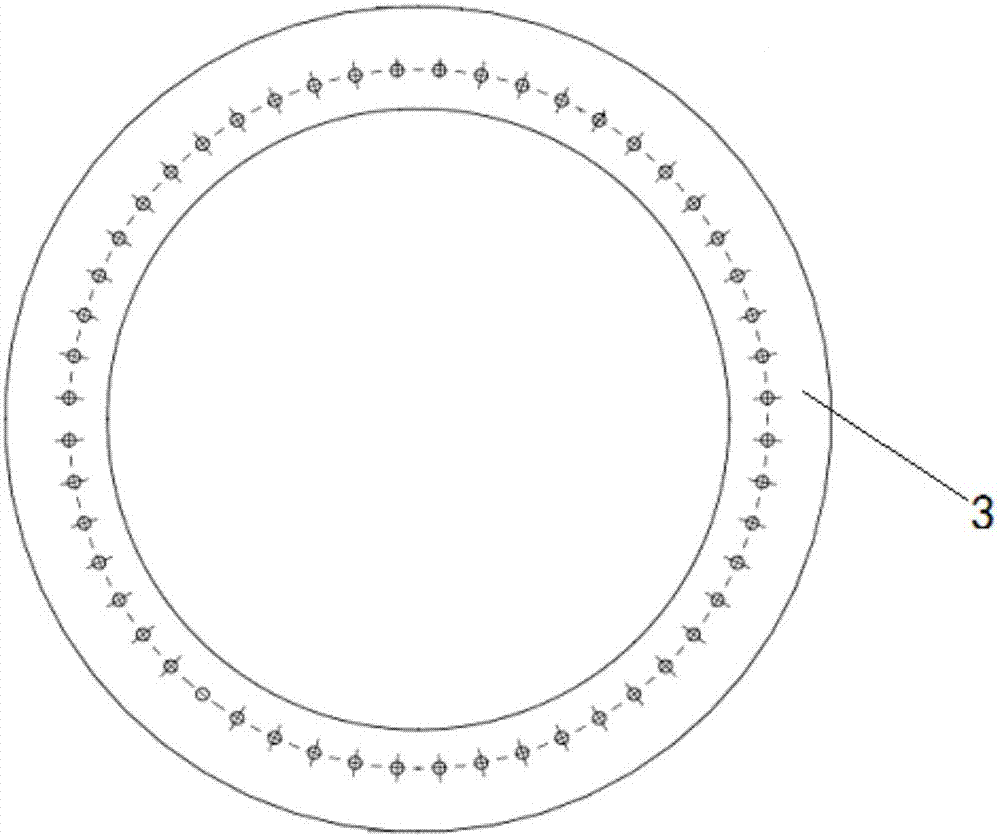

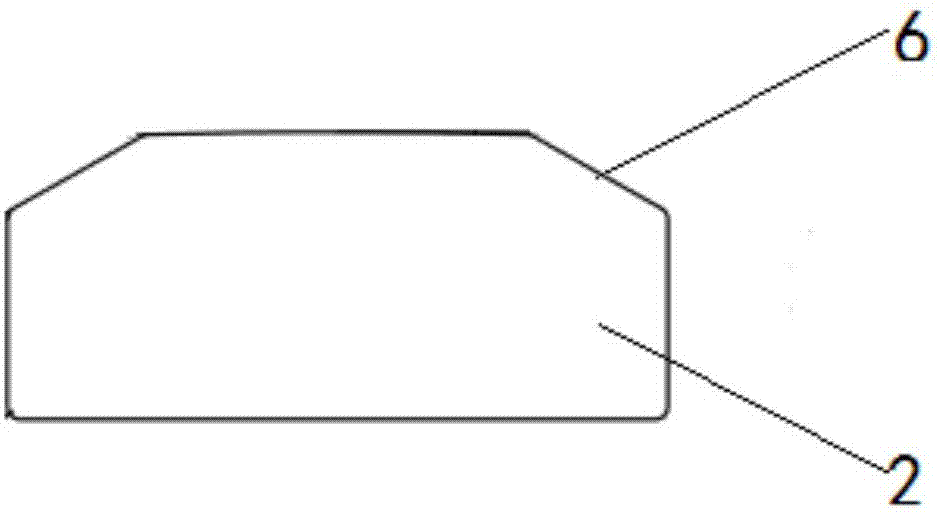

[0027] Such as Figure 1-3 The shown motor rotor includes a rotor core 1 and permanent magnets, and the permanent magnets are adhered to the surface of the rotor core 1 . The rotor core 1 is formed by stacking the rotor punches 3, and the surface of the rotor core 1 and the permanent magnet 2 is a regular polygon, so that the permanent magnet 2 has an inclination angle, and then the rotor core 1 is connected to the rotor core. 1 Pasting, the process is simple and saves labor costs, and the accuracy of the inclination angle is relatively easy to control, which ensures the performance of the motor. In addition, the number of sides is equal to the number of stages 2P designed by the motor, and a round hole 4 is opened in the middle of the rotor core 1, and the round hole 4 is matched with the motor shaft. Positioning holes 5 are evenly distributed along the circumference of the rotor core 1, and the number of the positioning holes 5 is also equal to the number of stages 2P desig...

Embodiment 2

[0031] Such as figure 1 , 2 A motor rotor shown in and 4 includes a rotor core 1 and permanent magnets, and the permanent magnets are adhered to the surface of the rotor core 1 . The rotor core 1 is formed by stacking the rotor punches 3, and the surface of the rotor core 1 and the permanent magnet 2 is a regular polygon, so that the permanent magnet 2 has an inclination angle, and then the rotor core 1 is connected to the rotor core. 1 Pasting, the process is simple and saves labor costs, and the accuracy of the inclination angle is relatively easy to control, which ensures the performance of the motor. In addition, the number of sides is equal to the number of stages 2P designed by the motor, and a round hole 4 is opened in the middle of the rotor core 1, and the round hole 4 is matched with the motor shaft. Positioning holes 5 are evenly distributed along the circumference of the rotor core 1, and the number of the positioning holes 5 is also equal to the number of stages...

Embodiment 3

[0035] Such as figure 1 , 2 A motor rotor shown in , 3 and 5 includes a rotor core 1 and a permanent magnet, and the permanent magnet is adhered to the surface of the rotor core 1 . The rotor core 1 is formed by stacking the rotor punches 3, and the surface of the rotor core 1 and the permanent magnet 2 is a regular polygon, so that the permanent magnet 2 has an inclination angle, and then the rotor core 1 is connected to the rotor core. 1 Pasting, the process is simple and saves labor costs, and the accuracy of the inclination angle is relatively easy to control, which ensures the performance of the motor. In addition, the number of sides is equal to the number of stages 2P designed by the motor, and a round hole 4 is opened in the middle of the rotor core 1, and the round hole 4 is matched with the motor shaft. Positioning holes 5 are evenly distributed along the circumference of the rotor core 1, and the number of the positioning holes 5 is also equal to the number of sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com