Manufacturing method for measurement clamp of steering column based on 3D printing technology

A measurement fixture and 3D printing technology, applied in the direction of digital output to printing unit, input/output process of data processing, instruments, etc., can solve the problems of affecting measurement results, poor installation repeatability, inconsistency, etc., and achieve good installation repeatability , Improve the production quality, the effect of precise fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

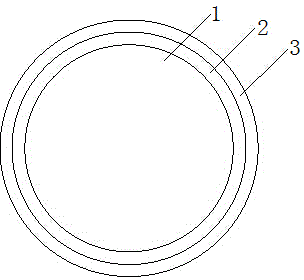

[0017] see figure 1 The driving rod measurement fixture includes the driving rod 1, the silicone bushing 2 and the metal shell 3. In order to prevent the steering rod 1 from being scratched during the installation of the measuring fixture, the driving rod measuring fixture includes the metal shell 3 and the silicone bushing 2; The production method is: use 3D printing technology to scan the measuring point of the driving rod (that is, point T) to obtain point cloud data, and obtain the 3D data of the driving rod measuring fixture after processing such as matching and smoothing, so as to carry out 3D printing of the driving rod measuring fixture production; the specific steps are as follows:

[0018] 1) In the image data software in the computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com