Stamping die for automobile left suspension installation inner-plate

A stamping die and left suspension technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low stamping accuracy and high product rework rate, and achieve the effect of high stamping processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

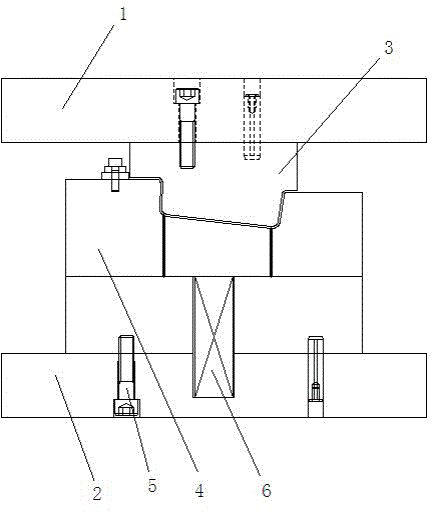

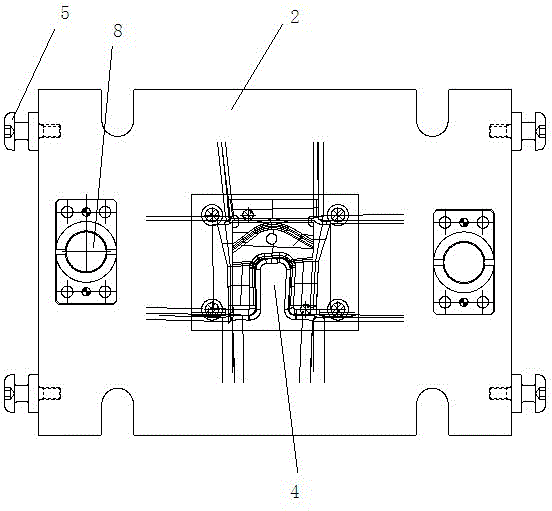

[0012] see figure 1 and 2 , the stamping die of the inner panel installed on the left suspension of the automobile has an upper template 1 and a lower template 2, the lower part of the upper template 1 is provided with a punch 3, the upper part of the lower template 2 is provided with a die 4, and the die 4 is provided with a positioning hole 8 , The positioning hole 8 is matched with the positioning column (not shown in the figure) provided on the punch 3 .

[0013] A spring 6 is arranged between the die 4 and the lower template 2, and when the punch 3 falls, its impact on the die 4 is buffered.

[0014] Lifting lugs 5 are also provided around the lower template 2 to facilitate the handling and movement of the stamping die.

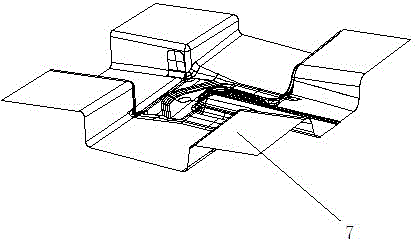

[0015] image 3 Product 7 in , that is, the product processed by the above stamping die.

[0016] The above content is only an example and description of the structure of the present invention. Those skilled in the art make various modifications or s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com