Gate valve rapid laser welding device

A laser welding and fast technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as affecting welding progress, welding failure, inability to adjust and throttle, etc., to facilitate reuse and improve welding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

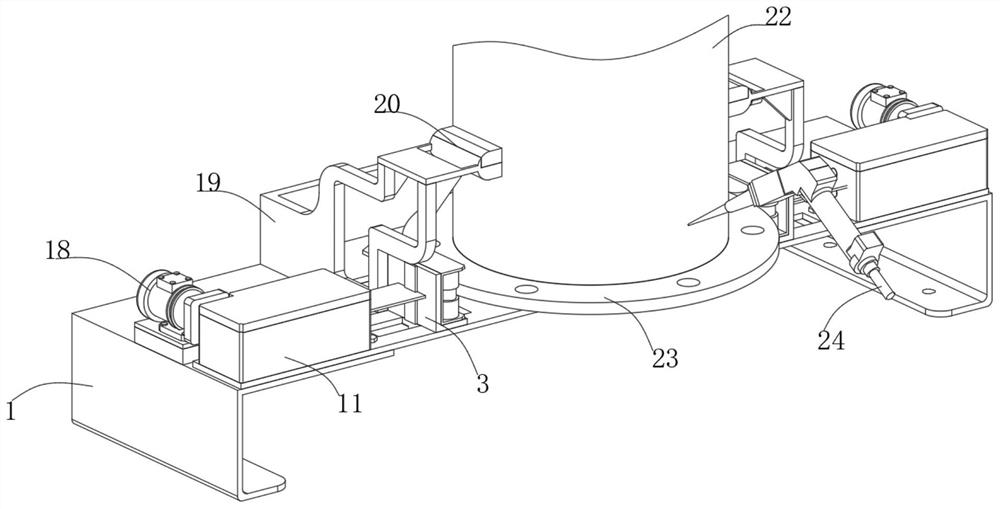

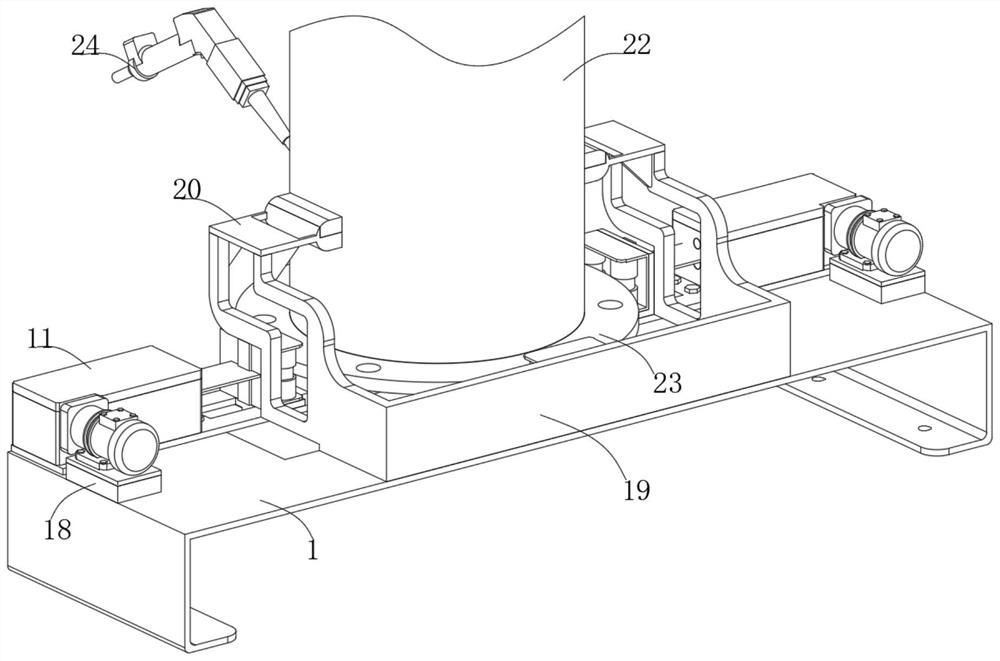

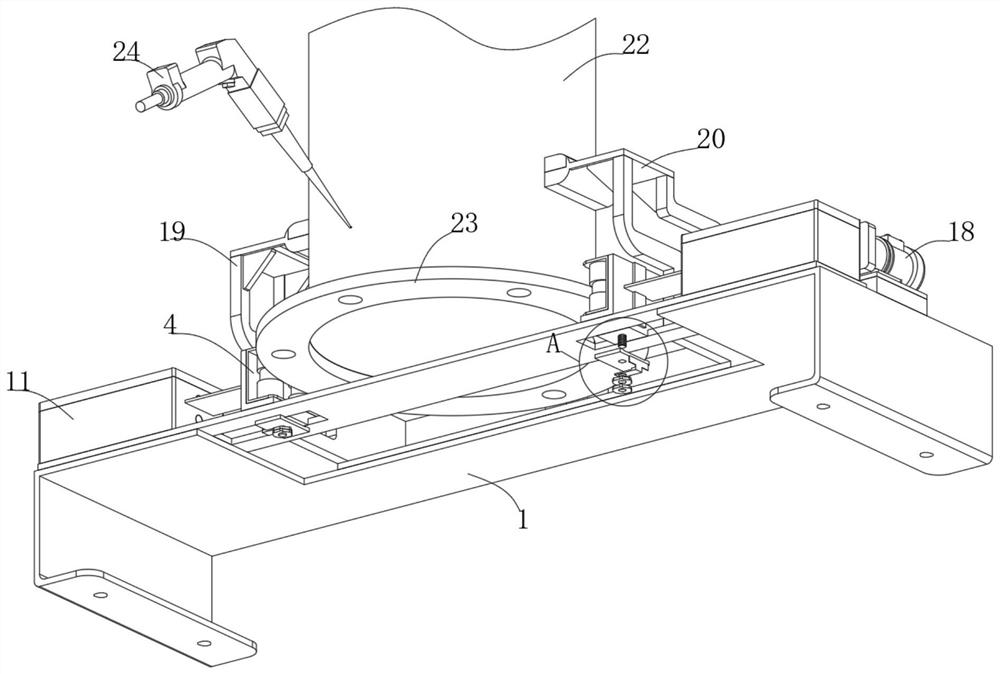

[0024] Example 1, such as Figure 1-6 As shown, the present invention provides a fast laser welding device for gate valves, including a base 1 and a laser welding device 24. The establishment of the base 1 provides an installation basis for other functional parts of the equipment. The structure and principle of the laser welding device 24 belong to the prior art , will not be described in detail here, and its model can be selected according to the actual situation. The establishment of the laser welding device 24 enables the equipment to effectively realize its due functions. For the installation and setting of other functional parts of the equipment, there are moving slots on both sides of the center of the top of the mounting plate 2. The setting of the moving slots facilitates the installation and setting of the moving frame 3, and at the same time restricts the moving position of the moving frame 3. Each moving slot has a Sliding is provided with mobile frame 3, and the es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com