Ultrasonic bolt stress detection device

A technology for detecting device and bolt stress, applied in the direction of measuring device, measuring force, instrument, etc., can solve problems such as too tight or too loose bolts, collapse of the overall structure, inconvenient use, etc., to prevent the probe from falling off, easy to move, and convenient The effect of storing the probe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

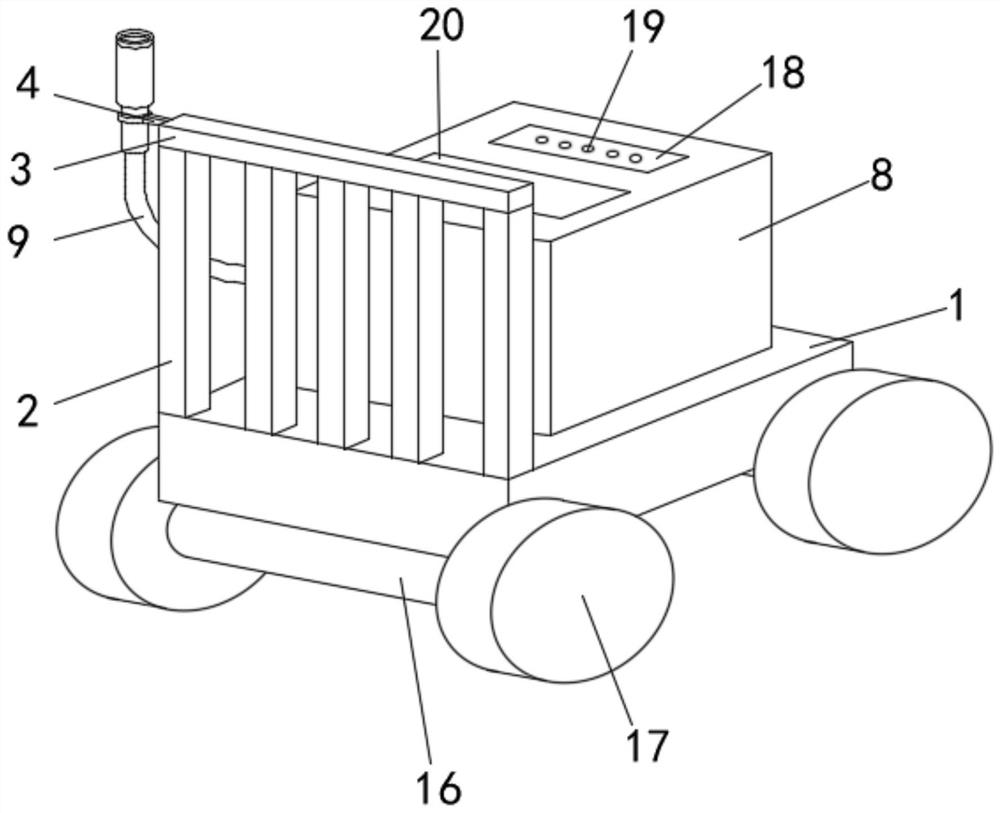

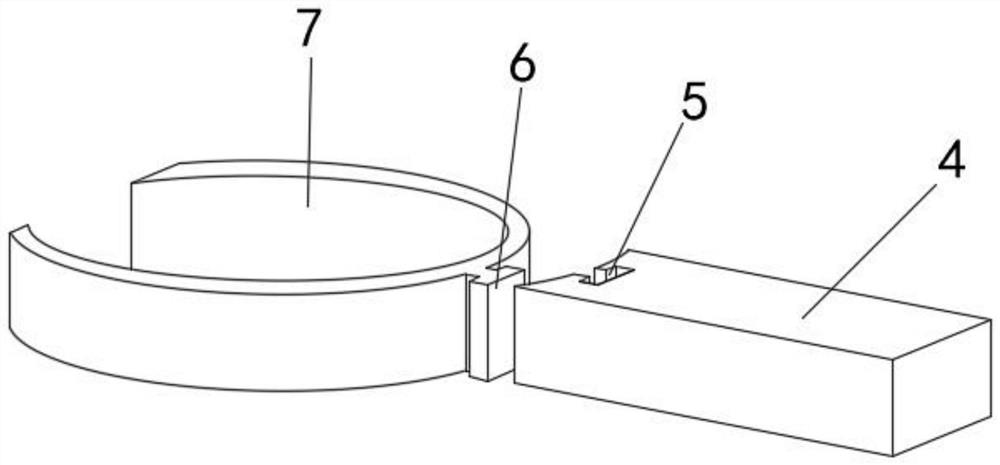

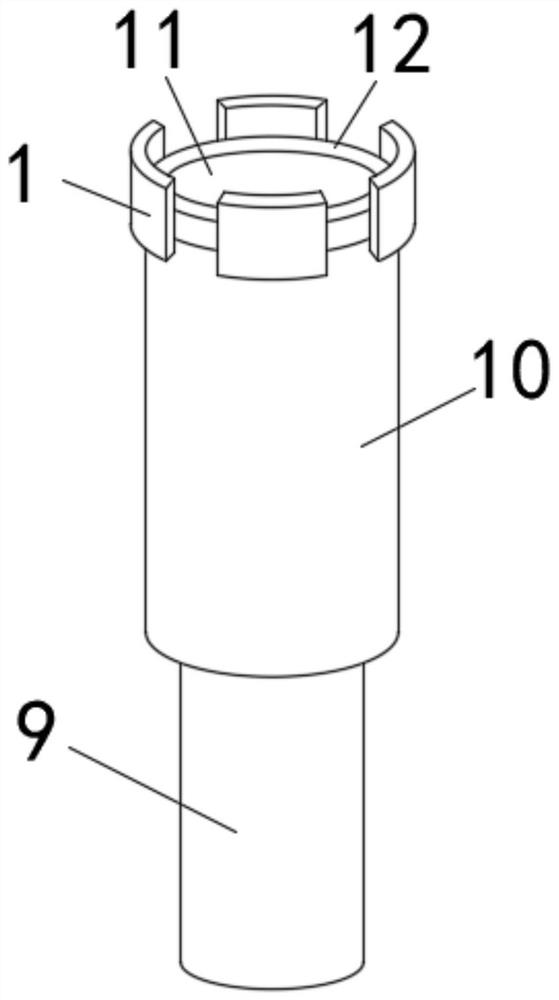

[0027] One end above the detection device base 1 is provided with an ultrasonic detection device body 8, one end of the ultrasonic detection device body 8 is electrically connected to a probe wire 9, and one end of the probe wire 9 is provided with an electromagnetic coil compartment 10, and the electromagnetic coil compartment 10 is provided with a detection probe 11 , and one end of the electromagnetic coil chamber 10 is provided with an electromagnetic adsorption metal ring 12 .

Embodiment 2

[0029] One end of the electromagnetic coil warehouse 10 is provided with a telescopic rod 13, and one end of the telescopic rod 13 is provided with a bolt buckle plate 14, and the outer side of the telescopic rod 13 is provided with a return spring 15, and the two ends of the telescopic rod 13 and the return spring 15 are The electromagnetic coil chamber 10 and the bolt buckle plate 14 are respectively connected, and the number of the telescopic rod 13 , the bolt buckle plate 14 and the return spring 15 are all provided in four groups.

Embodiment 3

[0031] A wheel shaft 16 is arranged under the base 1 of the detection device, and a moving roller 17 is arranged at one end of the wheel shaft 16, and there are multiple groups of the wheel shaft 16 and the moving roller 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com