Brake disc processing technology and tooling

A processing technology and brake disc technology, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of low processing efficiency and affect the production efficiency of brake discs, and achieve the effects of improving production efficiency, fitting precision, and improving grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

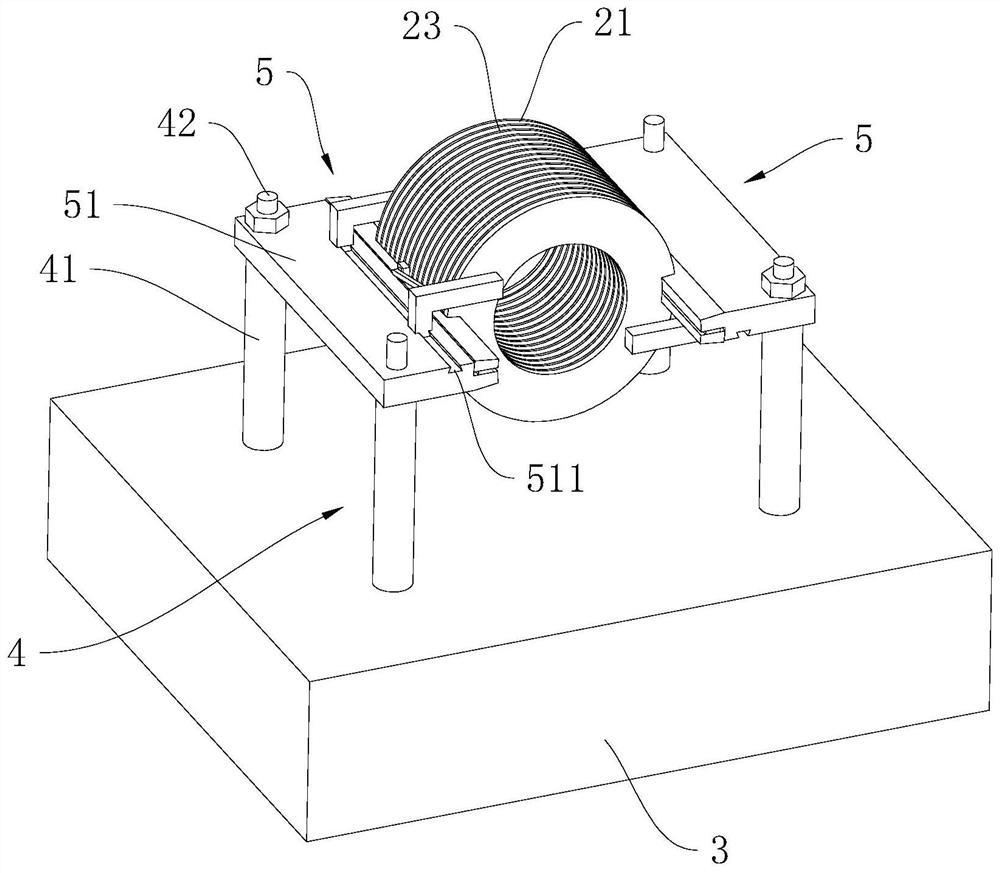

[0052] Attached to the following Figure 1-8 This application will be described in further detail.

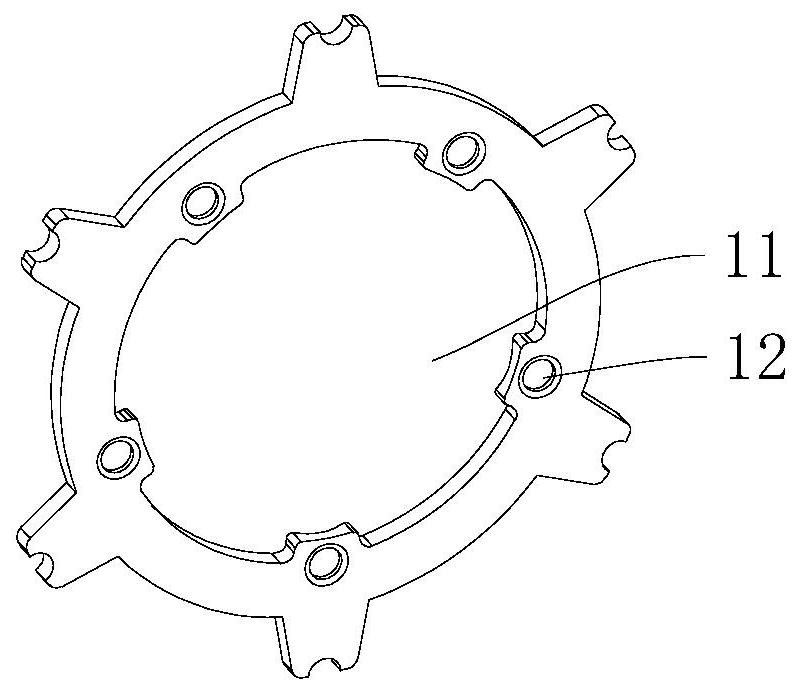

[0053] refer to figure 1 , the brake disc is annular, and the brake disc is provided with a central hole 11 and a mounting hole 12 .

[0054] The embodiment of the present application discloses a processing technology for a brake disc.

[0055] The machining process of brake disc includes blanking, inner hole, grinding inner hole, drilling mounting hole and grinding end face.

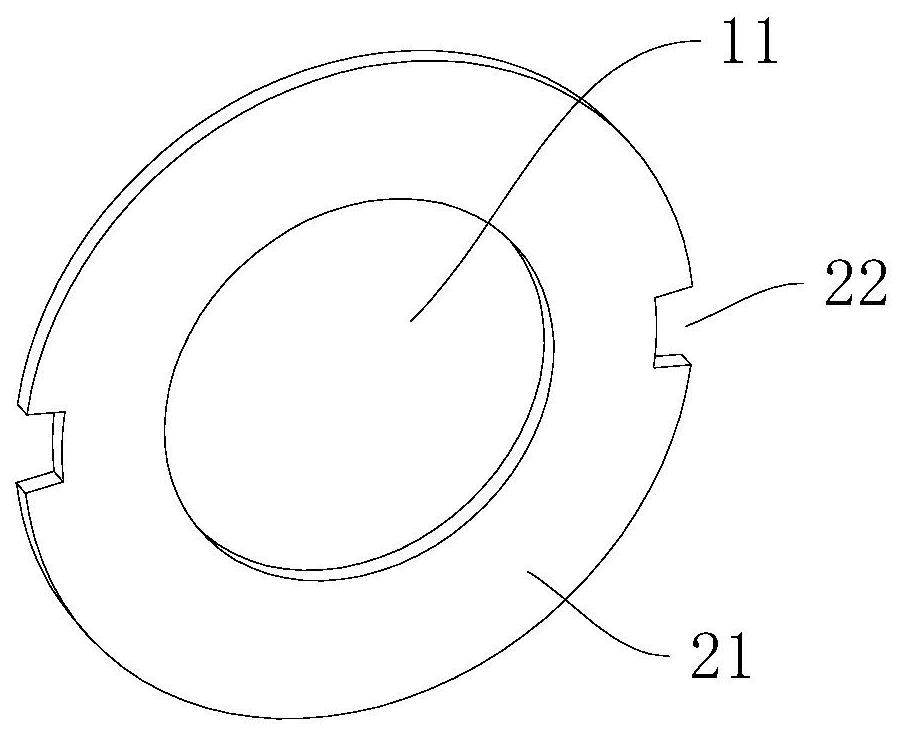

[0056] Step 1: Blanking. refer to figure 2, the sheet material is placed on the worktable, a circular substrate 21 is processed by laser cutting or punching, and two positioning grooves 22 are machined on the outer periphery of the substrate 21 that are symmetrical about the axis of the substrate 21, and the positioning grooves 22 are along the substrate 21. At the same time, the positioning groove 22 has three side walls, wherein the two opposite side walls of the positioning groove 22 along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com