LOCA bonding machine

A laminating machine and laminating technology are applied in the direction of mechanical equipment, connecting components, and devices for coating liquid on the surface. Good lamination effect, high production efficiency, and precise lamination action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

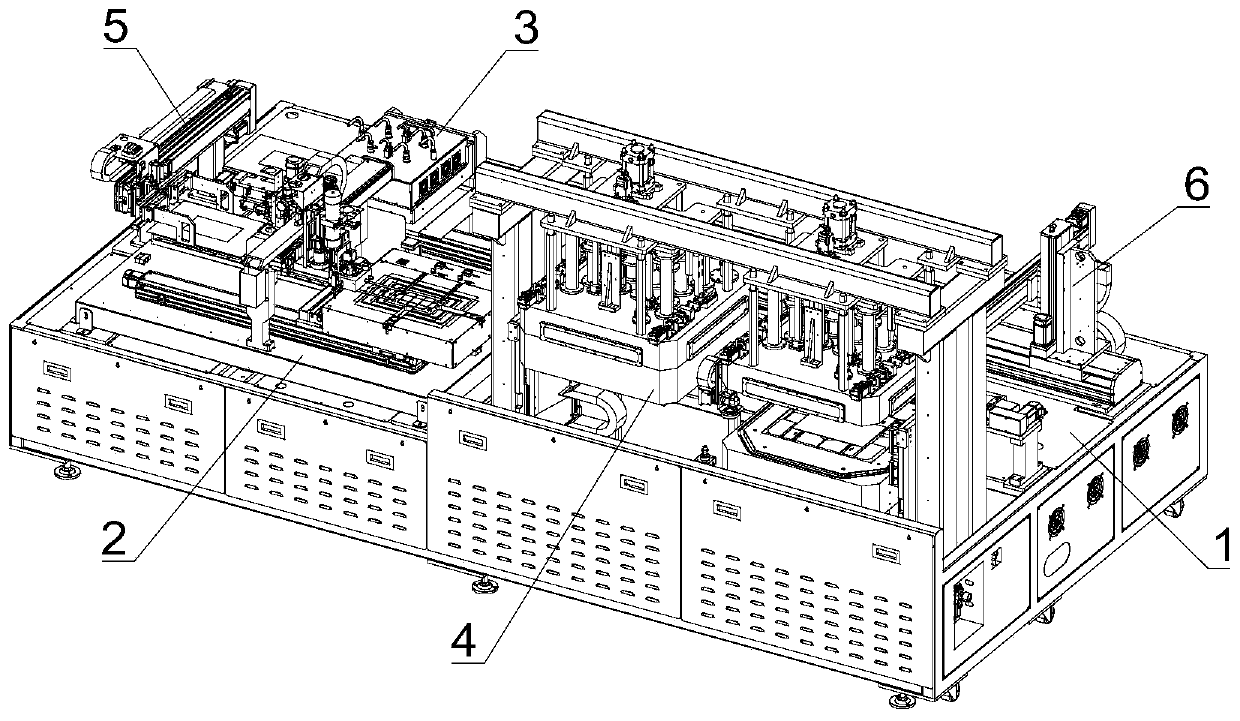

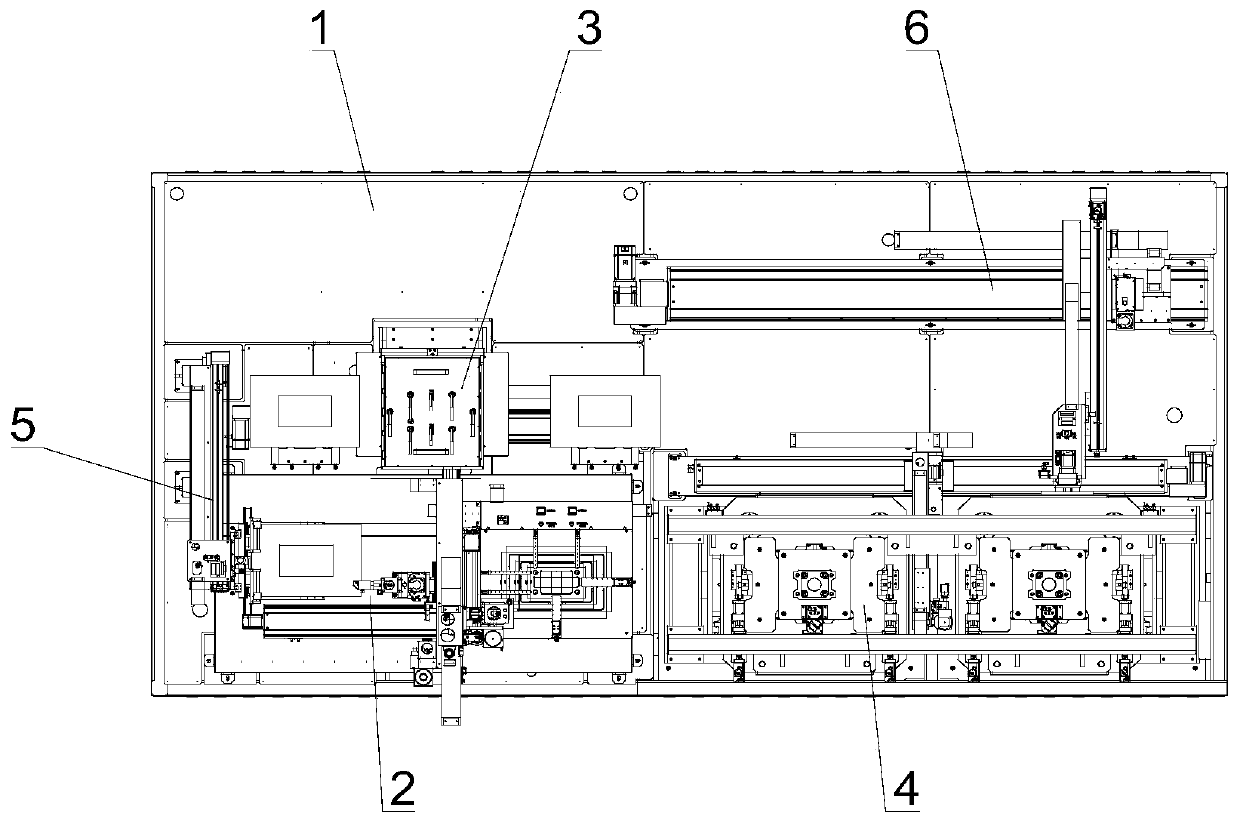

[0041] see Figures 1 to 11 As shown, the present embodiment provides a LOCA laminating machine, taking the lamination of two workpieces of TP and LCM as an example, which mainly includes an installation platform 1, a dispensing station 2, a curing station 3, a laminating station 4, a first moving material handling 5 and the second material handling 6.

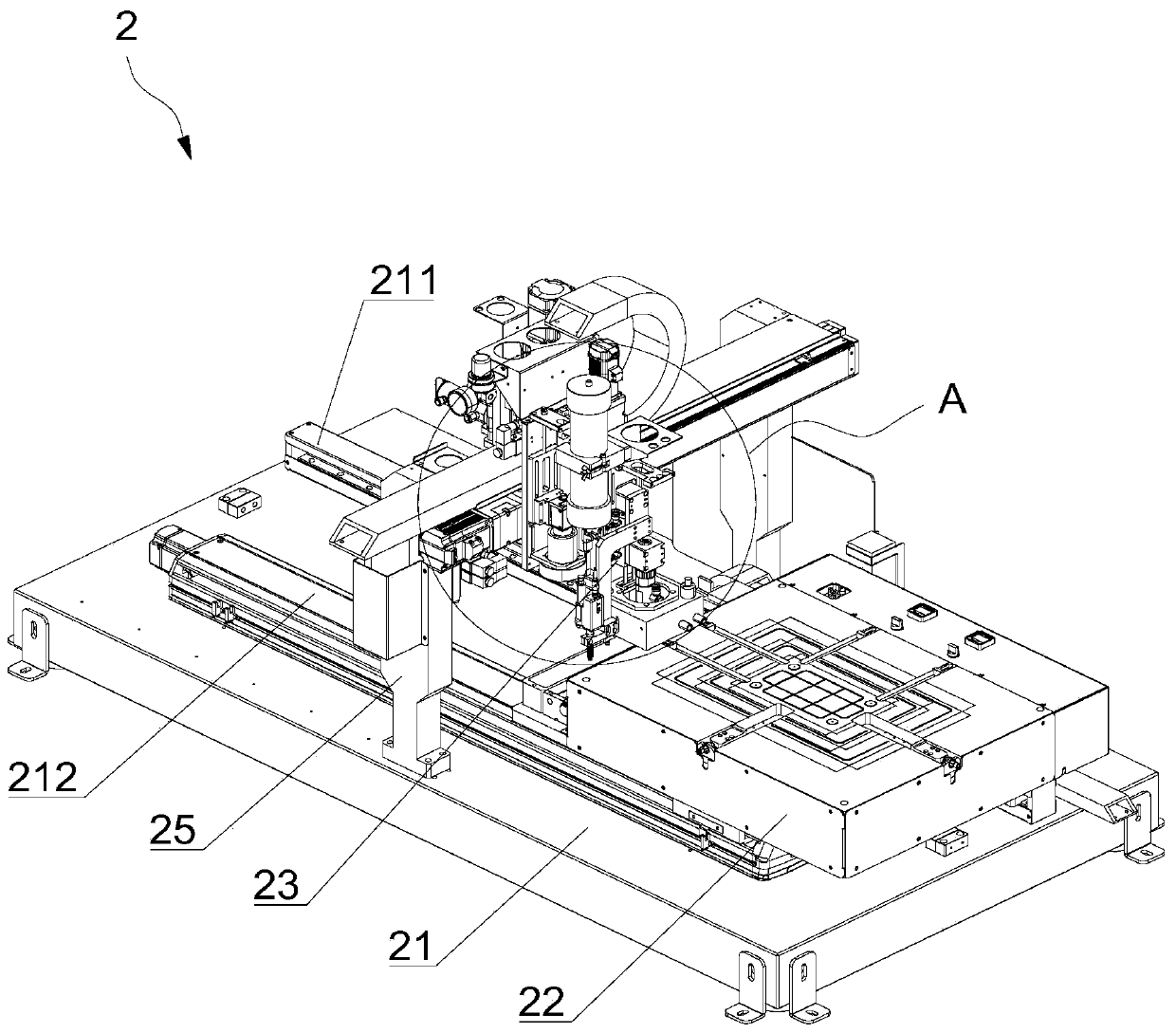

[0042] The dispensing station 2 is used for applying glue to the TP that is loaded, and includes a base 21 and a dispensing platform 22 , a dam glue assembly 23 and a surface glue assembly 24 arranged on the base 21 .

[0043] The base 21 is provided with a parallel X-axis guide rail 211 and an X-axis linear motor 212, the X-axis guide rail 211 is provided with a support slider, the X-axis linear motor 212 is provided with a driving slide, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com