Weatherproof vanes with self-closing function

An automatic closing, fan blade technology, applied to fan blades. It can solve problems such as equipment and product loss, rainwater intrusion/inflow into the room, and interior space impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

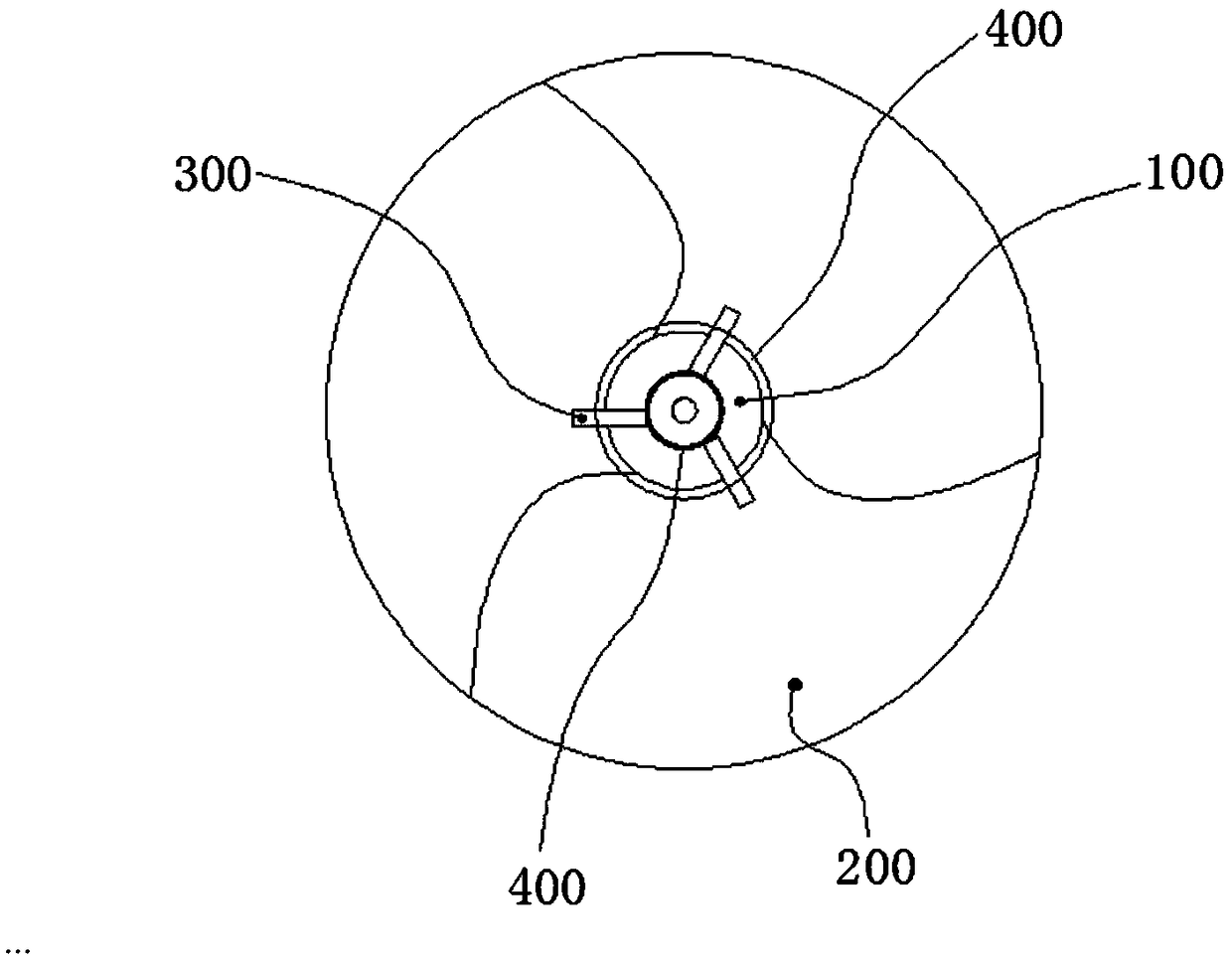

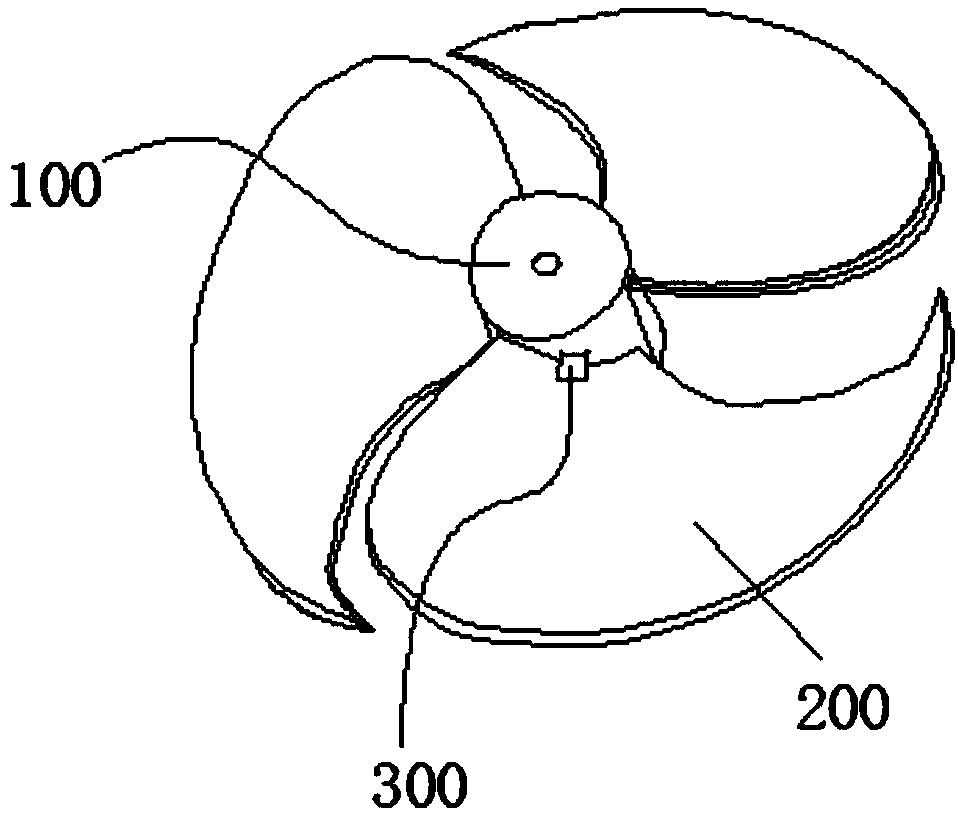

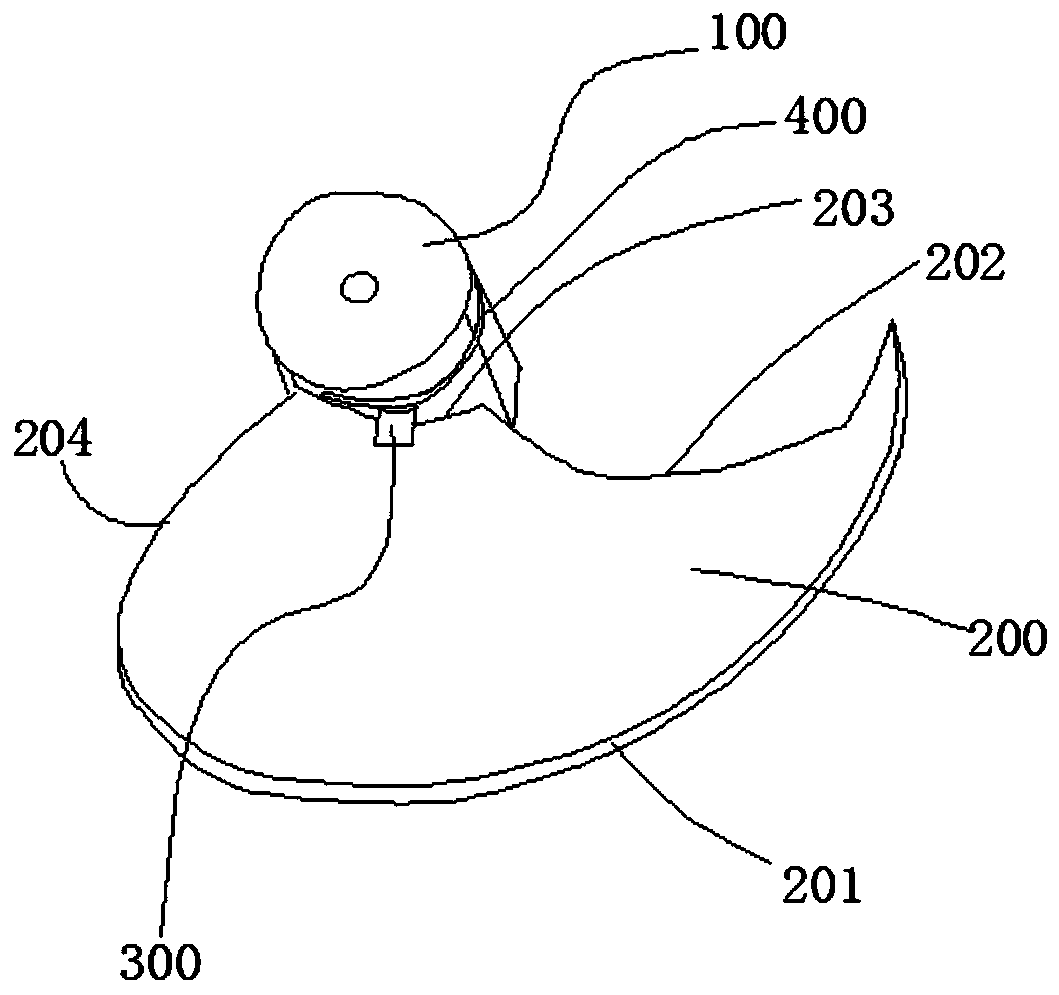

[0023] The dislocation mechanism is dislocated through the gravity difference on the blade and the gear 400, because the same blade needs to produce a weight difference, so the embodiment is illustrated by using the moon-shaped fan blade 200. The specific technical solution is as follows:

[0024] refer to Figure 1 to Figure 3 , the blade is divided into four sides: the connecting inner edge 203 facing the main shaft 100, the circular arc outer edge 201 opposite to the connecting inner edge 203 and forming an arc shape, and the second connecting inner edge 203 and the circular arc outer edge 201 respectively. An inner side 204 and a second inner side 202, the weight of the first inner side 204 is greater than that of the second inner side 202, and the motive force of dislocation is realized by the weight difference between the two sides. Of course, in order to ensure its sealing, the blades The first inner side 204 is adapted to the arc shape of the second inner side 202 of t...

Embodiment 2

[0029] The dislocation mechanism uses the cooperation of card displacement and guide rail 600, because the blade does not need to produce weight difference, so this embodiment is illustrated by fan-shaped fan blade, and its specific technical solution is as follows:

[0030] refer to Figure 4 to Figure 6 , the misalignment mechanism is a guide rail 600 arranged on the main shaft 100 and a linkage rod 900 arranged between each adjacent two blades 200 , and the reset mechanism is a return spring 800 arranged in the guide rail 600 . In the misalignment, the linkage rod 900 is used to ensure that the misalignment angles between multiple blades are unified and consistent.

[0031] Further design of the above technical solution: the guide rail 600 includes a first guide rail 602 that fixes the card when the blades are closed and a second guide rail 601 that fixes the card when the blades are unfolded, and a second limit position is set on the second guide rail 601 Buckle 700 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com