Intelligent hot press and hot pressing control method thereof

A technology of intelligent hot press and control mechanism, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve problems that affect the quality and service life of product hot pressing, material fracture, and product defect rate of hot pressing molds, etc. Achieve the effects of improving controllability and flexibility, prolonging service life, ensuring quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

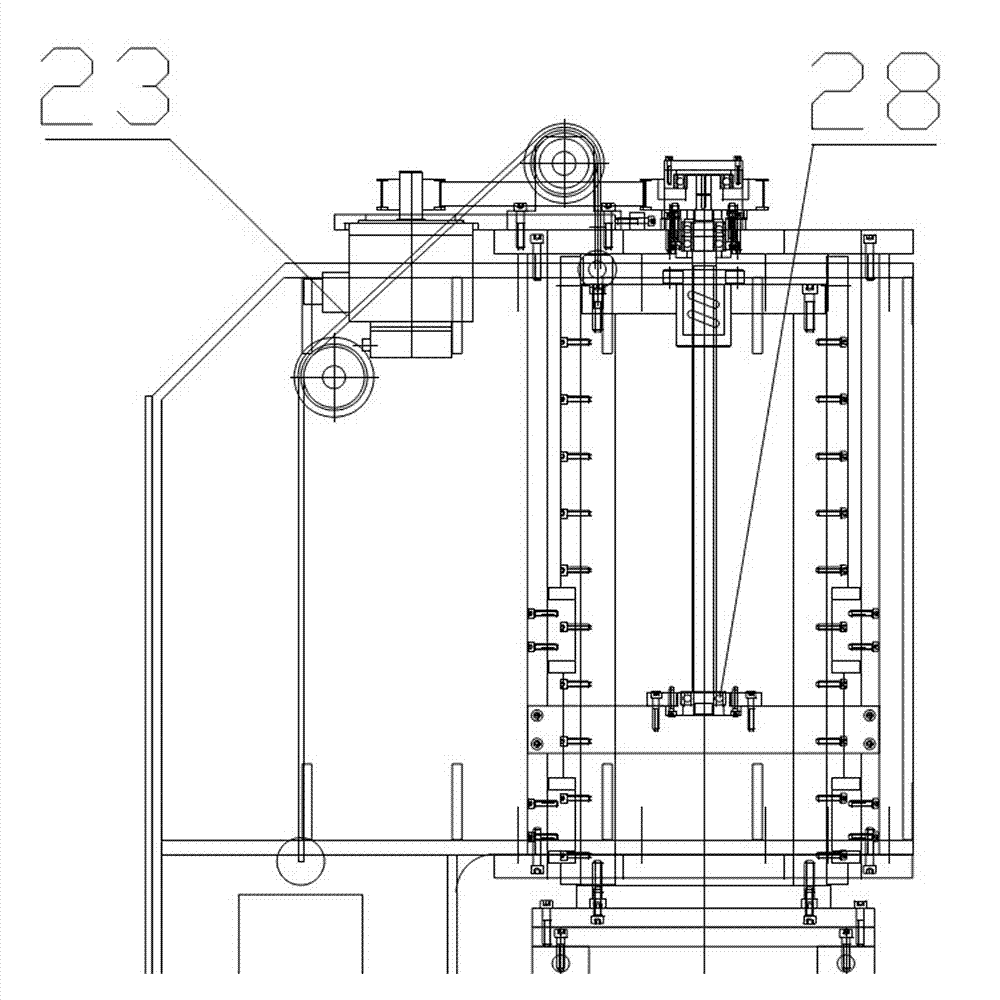

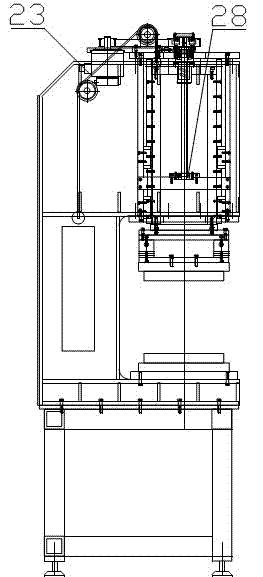

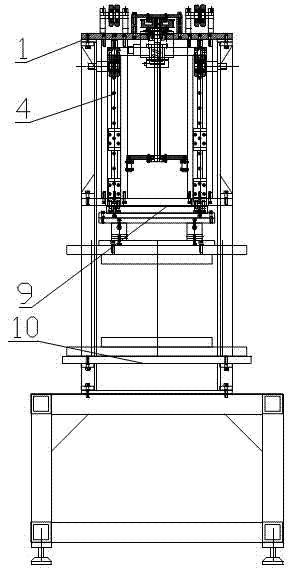

[0047] Such as Figure 1 to Figure 3 As shown, this example provides an intelligent heat press, including:

[0048] Rack 1;

[0049] The control mechanism 23 installed on the frame 1, the control mechanism 23 realizes the segmented hot pressing control of the mold through the servo motor, so as to form segmented hot pressing;

[0050] The limit mechanism 28 installed on the frame 1, the limit mechanism 28 is used to limit the position of the hot pressing;

[0051] The positioning and guiding mechanism 4 fixed on the frame 1, the positioning and guiding mechanism 4 is used to realize the positioning and guiding of the hot pressing process;

[0052] The upper worktable 9, the upper worktable 9 is connected with the control mechanism 23, and realizes the downward pressure and back pressure movement through the positioning guide mechanism 4; and,

[0053] The lower worktable 10, which is fixedly installed on the frame 1, is used to cooperate with the upper worktable 9 to realiz...

Embodiment 2

[0059] On the basis of Embodiment 1, the control mechanism 23 in this embodiment realizes segmented hot-press control of pressure, distance, speed and time through a servo motor.

[0060] The segmented hot-pressing control realizes the segmented control of the hot-pressing process of the mould, which is also called staged control. The hot-pressing control of each stage realizes the hot-pressing through a set pressure, distance and speed. And keep the hot pressing time for a certain time, and then carry out the hot pressing control of the next stage; the hot pressing control of one stage can have different control parameters from the hot pressing control of the previous stage and the next stage, and the control parameters include Pressure, distance, speed and time, therefore, the hot pressing process of the mold can be divided into different controllable stages, making the hot pressing control process flexible and changeable, and can well adapt to various materials or products w...

Embodiment 3

[0062] On the basis of Embodiment 2, this example also includes a grating detection device. The grating detection device detects whether there is danger between the upper worktable 9 and the lower worktable 10 through the safety grating. The motor stops the pressing motion of the upper worktable 9, and simultaneously controls the upper worktable 9 to realize the back pressure.

[0063] The safety grating is a photoelectric safety protection device, also known as a safety protector, a punch protector, and an infrared safety protection device. The safety grating generates a protective light curtain by emitting infrared rays. When the light curtain is blocked, the device sends a light-shielding signal to control Potentially dangerous mechanical equipment stops working to avoid safety accidents.

[0064] In the existing technology, there will be certain safety accidents, such as the hot press machine being caught by workers or other dangerous objects that do not belong to the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com