Hot press for consolidated composite floors

A technology of strengthening composite flooring and hot press machine, which is applied in the direction of joining, laminating, and laminating devices of wooden veneers, which can solve the problems of low bonding strength, poor hot pressing effect, complex structure, etc., and achieve hot pressing effect Good, easy to operate, high bonding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

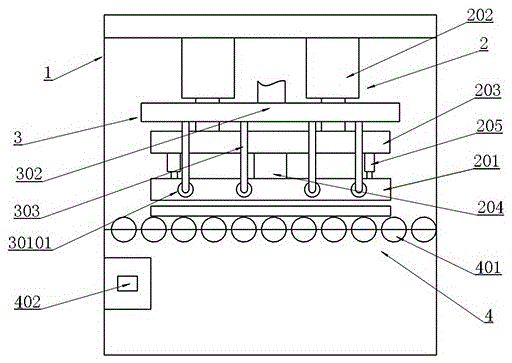

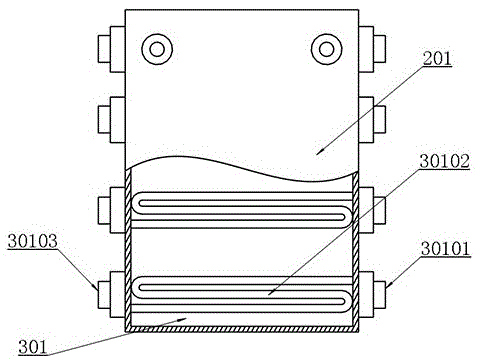

[0020] Example: as attached figure 1 and attached figure 2 As shown, a heat press machine for strengthening composite flooring includes a frame 1, a compacting unit 2 arranged in the frame 1 and a heating unit 3 arranged on the compacting unit 2, the A delivery unit 4 for floor transportation is provided below the pressing unit 2. The pressing unit 2 includes a hot pressing plate 201, a main cylinder 202 and a balance between the hot pressing plate 201 and the main air cylinder 202. plate 203, and the heating unit 3 includes several sets of heating pipes 301 that are independent from each other. The arrangement of the balance plate 203 makes the bonding between the hot pressing plate 201 and the floor more closely and evenly, and further improves the bonding strength of the wear-resistant layer, the decorative layer and the base layer.

[0021] The pressing unit 2 further includes a connecting spindle 204 and a fine-tuning cylinder 205 arranged between the balance plate 203...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com