Multistation pattern ironing machine

The technology of a station hot stamping machine and a position hot stamping machine is applied to the printing press, rotary printing machine, printing and other directions. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

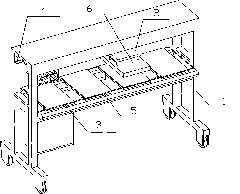

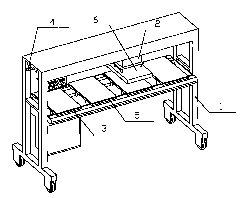

[0017] Implementation mode one: if figure 1 As shown, the multi-station hot stamping machine includes a frame 1, an upper mold assembly 2, and a lower mold assembly 3, wherein the upper mold assembly includes a hot pressing plate 6, which is arranged on a lifting cylinder, It is characterized in that: the lifting cylinder is arranged on the horizontal rail 4, and is equipped with a horizontal stepping drive device; there are four lower mold assemblies 3, which are arranged sequentially under the horizontal rail 4, and the horizontal stepping drive device Driven by the drive, the upper die assembly 2 can be moved to the top of each lower die assembly 3 in turn.

[0018] The horizontal stepping driving device includes a stepping motor, a transmission mechanism and a programmable controller, and the transmission mechanism is a rack and pinion transmission mechanism or a synchronous belt transmission mechanism. Each lower mold assembly is provided with a high temperature resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com