Carbon-carbon crucible support and preparation method thereof

A technology of prefabricated body and carbon fiber cloth, which is applied in chemical instruments and methods, self-melting liquid pulling method, crystal growth, etc., can solve the problems of increased amount of dipping, high price of graphite molds, increased production costs, etc., and achieves favorable Industrialized production, high market application prospects, and the effect of increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

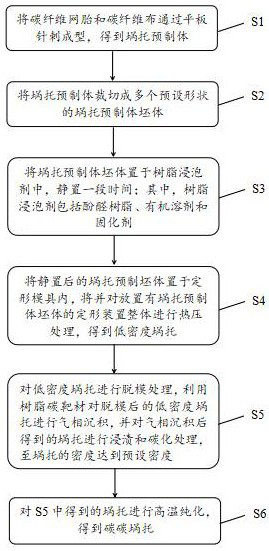

[0115] When performing high-temperature purification, it has little effect on the density of the crucible holder; high-temperature purification mainly removes some metal and non-metallic impurities in the crucible holder; when the application field of the crucible holder does not require the content of metal impurities in the crucible holder, carbon The preparation method of support comprises:

[0116] S1: The carbon fiber mesh tire and carbon fiber cloth are formed by needle punching on a flat plate to obtain a crucible support prefabricated body;

[0117] S2: cutting the crucible support prefabricated body into a plurality of prefabricated crucible support prefabricated bodies;

[0118] S3: Put the crucible holder prefabricated body in the resin soaking agent and let it stand for 1 hour; wherein, the resin soaking agent includes phenolic resin, organic solvent and curing agent;

[0119] S4: Put the prefabricated body of the crucible holder after standing in the shaping mold...

Embodiment 2

[0124] S1: The carbon fiber mesh tire and carbon fiber cloth are formed by needle punching on a flat plate to obtain a crucible support prefabricated body;

[0125] S2: cutting the crucible support prefabricated body into a plurality of prefabricated crucible support prefabricated bodies;

[0126] S3: Put the crucible holder prefabricated body in the resin soaking agent and let it stand for 1 hour; wherein, the resin soaking agent includes phenolic resin, organic solvent and curing agent;

[0127] S4: Put the prefabricated body of the crucible holder after standing in the shaping mold, and carry out hot pressing treatment on the whole shaping device with the prefabricated body of the crucible holder at 120°C. The hot pressing time is 9 hours, and a low Density crucible holder;

[0128] S5: Perform demoulding treatment on the low-density crucible holder, use resin carbon target material to perform vapor deposition on the demolded low-density crucible holder, impregnate the cru...

Embodiment 3

[0132] S1: The carbon fiber mesh tire and carbon fiber cloth are formed by needle punching on a flat plate to obtain a crucible support prefabricated body;

[0133] S2: cutting the crucible support prefabricated body into a plurality of prefabricated crucible support prefabricated bodies;

[0134] S3: Put the crucible support prefabricated body in the resin soaking agent, and let it stand for 1.5 hours; wherein, the resin soaking agent includes phenolic resin, organic solvent and curing agent;

[0135] S4: Put the prefabricated body of the crucible holder after standing still in the shaping mold, and perform hot pressing treatment on the whole shaping device with the prefabricated body of the crucible holder at 130°C. The hot pressing time is 6 hours, and a low Density crucible holder;

[0136] S5: Perform demoulding treatment on the low-density crucible holder, use resin carbon target material to perform vapor deposition on the demolded low-density crucible holder, impregnat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com