UV (ultraviolet) single-side adhesive tape with adhesive failure after ultraviolet irradiation and preparation method of adhesive tape

A post-irradiation, ultraviolet technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of insufficient adhesive force of the tape, poor adhesion loss effect, etc., and achieve good adhesion effect, high adhesion, no The effect of residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention also discloses a preparation method of UV single-sided adhesive tape that loses tack after being irradiated by ultraviolet rays, comprising the following steps:

[0021] (1) Take UV adhesive, curing additive, ethyl ester solution and toluene solution, prepare and stir the ethyl ester solution, toluene solution, UV adhesive and curing additive to form glue, and strictly prohibit sunlight exposure during glue mixing and production process;

[0022] (2) Coat the above-mentioned prepared glue on the transparent base film by direct coating, bake at 85°C-95°C for 2-4 minutes for curing treatment, and then cover the single-sided release film and send it to 45°C- 55 ℃ warm room for 23H-25H curing treatment.

Embodiment 1

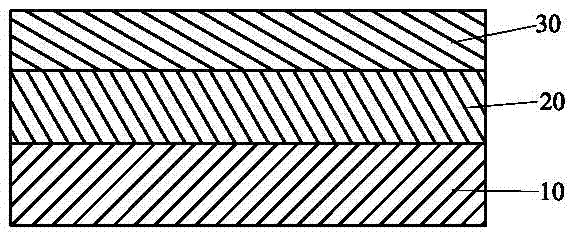

[0025] One includes a transparent base film 10 , a UV adhesive layer 20 and a single-side release film 30 . The UV adhesive layer 20 is coated on the surface of the transparent base film 10, and the single-sided release film 30 is coated on the surface of the UV adhesive layer 20; and, the UV adhesive layer 20 includes the following weight percentage components : UV adhesive 38%, curing additive 2%, ethyl ester 20% and toluene 40%. The transparent base film 10 is made of PET, and the thickness of the UV adhesive layer 20 is 8 μm.

[0026] A kind of preparation method of the UV one-sided adhesive tape that loses tack after ultraviolet irradiation comprises the following steps:

[0027] (1) Take UV adhesive, curing additive, ethyl ester solution and toluene solution, prepare and stir the ethyl ester solution, toluene solution, UV adhesive and curing additive to form glue, and strictly prohibit sunlight exposure during the glue mixing and production process.

[0028] (2) Apply ...

Embodiment 2

[0030] One includes a transparent base film 10 , a UV adhesive layer 20 and a single-side release film 30 . The UV adhesive layer 20 is coated on the surface of the transparent base film 10, and the single-sided release film 30 is coated on the surface of the UV adhesive layer 20; and, the UV adhesive layer 20 includes the following weight percentage components : UV adhesive 40%, curing additive 2.5%, ethyl ester 19.5% and toluene 38%. The transparent base film 10 is made of PET, and the thickness of the UV adhesive layer 20 is 5 μm.

[0031] A kind of preparation method of the UV one-sided adhesive tape that loses tack after ultraviolet irradiation comprises the following steps:

[0032] (1) Take UV adhesive, curing additive, ethyl ester solution and toluene solution, prepare and stir the ethyl ester solution, toluene solution, UV adhesive and curing additive to form glue, and strictly prohibit sunlight exposure during the glue mixing and production process.

[0033] (2) Ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com