UV (Ultraviolet)-cured acrylate pressure-sensitive adhesive with low shrinkage rate and preparation method thereof as well as UV-cured acrylate pressure-sensitive adhesive tape with low shrinkage rate

An acrylate, low shrinkage technology, applied in the field of low shrinkage UV-curable acrylate pressure-sensitive adhesive tapes, can solve the problems of low shrinkage and high pressure-sensitive adhesive adhesion, and achieve low shrinkage and adhesion. Large, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

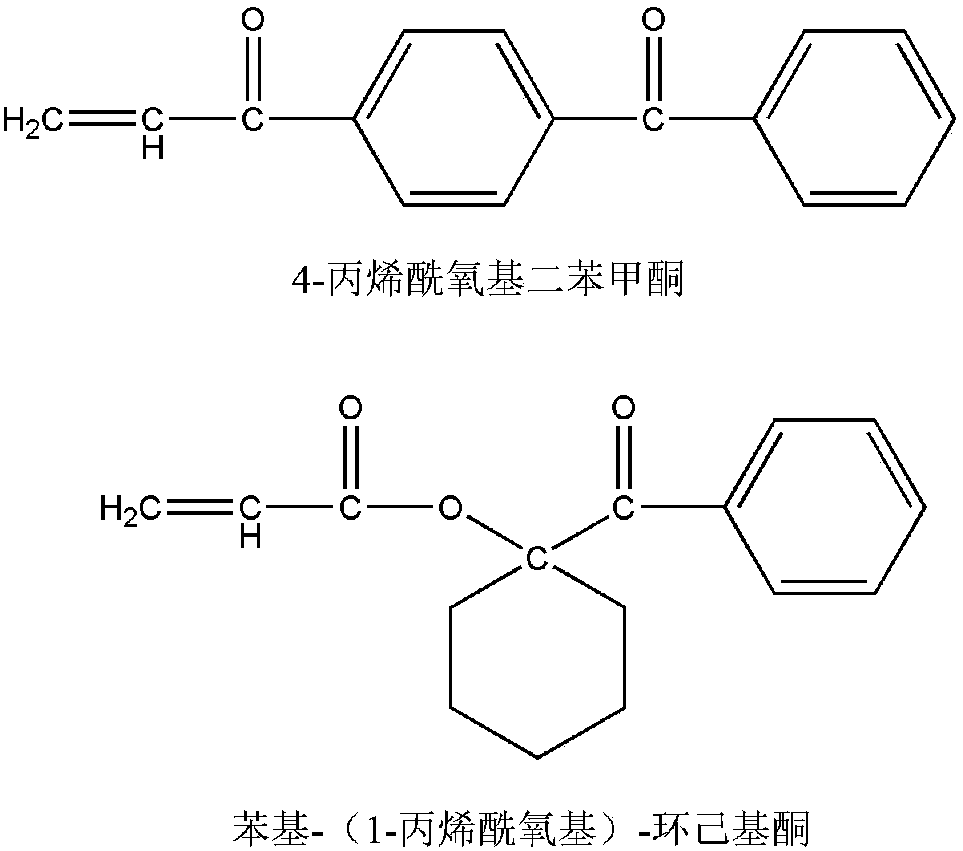

[0032] 1) After mixing 45g of butyl acrylate, 15g of isooctyl acrylate, 15g of vinyl acetate, 4.7g of acrylic acid, 2g of hydroxyethyl acrylate, and 0.3g of 4-acryloyloxybenzophenone, take 60 % with the solvent (ethyl acetate:toluene=5:3) of 75g, 0.15g initiator AIBN mixes and pours into the four-necked flask that thermometer, mechanical stirring (150rap / min) and condensing tube are equipped with, then be heated to 80 ℃ reaction, when the viscosity of the reaction system starts to increase, count 1h.

[0033] 2) After 1h, the remaining monomer, 75g of solvent (ethyl acetate: toluene = 5:3) and 0.075g of initiator AIBN were evenly added dropwise into the reaction system within 1h using a constant liquid funnel, and then incubated for 2h.

[0034] 3) Add the remaining 0.075g of initiator AIBN into the reaction system at one time, and then keep it warm for 1.5h.

[0035] 4) After heat preservation for 1.5 hours, add 18 g of polyvinyl acetate into the reaction system, adjust the ...

Embodiment 2

[0039] 1), mix 45g of butyl acrylate, 15g of isooctyl acrylate, 15g of vinyl acetate, 4.7g of acrylic acid, 2g of hydroxyethyl acrylate, and 0.3g of phenyl-(1-acryloyloxy)-cyclohexyl ketone Afterwards, get its 60% and 75g solvent (ethyl acetate: toluene=5:3), 0.15g initiator AIBN is mixed and poured into the four-necked flask that thermometer, mechanical stirring (150rap / min) and condenser pipe are housed , and then heated to 80°C for reaction, when the viscosity of the reaction system began to increase, timed for 1h.

[0040] 2) After 1 hour, the remaining monomer, 75g of solvent and 0.075g of initiator were evenly added dropwise into the reaction system within 1 hour using a constant liquid funnel, and then kept for 2 hours of reaction.

[0041] 3) Add the remaining 0.075g of the initiator into the reaction system at one time, and then keep it warm for 1.5h.

[0042] 4) After heat preservation for 1.5 hours, add 18 g of polyvinyl acetate into the reaction system, adjust the...

Embodiment 3

[0046] 1) After mixing 45g of butyl acrylate, 15g of isooctyl acrylate, 15g of vinyl acetate, 4.7g of acrylic acid, 2g of hydroxyethyl acrylate, and 0.3g of 4-acryloyloxybenzophenone, take 60 % with the solvent (ethyl acetate:toluene=5:3) of 75g, 0.15g initiator AIBN mixes and pours into the four-necked flask that thermometer, mechanical stirring (150rap / min) and condensing tube are equipped with, then be heated to 80 ℃ reaction, when the viscosity of the reaction system starts to increase, count 1h.

[0047] 2) After 1 hour, the remaining monomer, 75g of solvent and 0.075g of initiator were evenly added dropwise into the reaction system within 1 hour using a constant liquid funnel, and then kept for 2 hours of reaction.

[0048] 3) Add the remaining 0.075g of the initiator into the reaction system at one time, and then keep it warm for 1.5h.

[0049]4) After 1.5 hours of heat preservation reaction, add 18 g of polyvinyl acetal into the reaction system, adjust the rotation sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com