Re-peel-off type special double-faced adhesive sheet for fixing flexible printed circuit board

A flexographic printing, re-peelable technology, applied in the direction of adhesive type, ester copolymer adhesive, film/sheet adhesive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

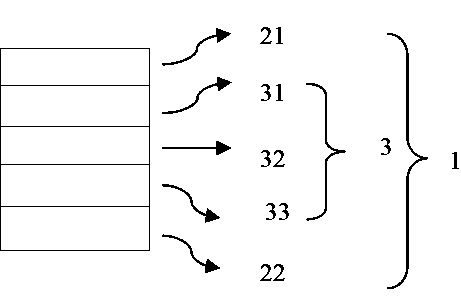

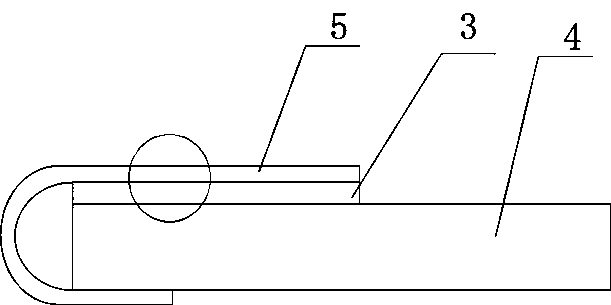

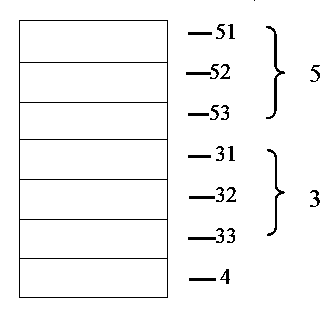

[0058] This embodiment provides a special double-sided adhesive sheet that can be peeled off again for fixing flexible printed circuit boards, such as figure 1 As shown, the double-sided adhesive sheet of this embodiment is a double-sided adhesive sheet 1 with a release liner, comprising a core material layer 32, a first adhesive layer 33 and a second adhesive layer 31, the described The core material layer 32 is disposed between the inside of the first adhesive layer 33 and the inside of the second adhesive layer 31, and also includes a first release liner 22 and a second release liner 21, the first release liner The pad 22 and the second release liner 21 are provided on the outer side of the first adhesive layer 33 and the second adhesive layer 31, respectively.

[0059] The core material of the above-mentioned core material layer is PET film, and the above-mentioned first adhesive layer includes the following components: in parts by weight, 100 parts by weight of acrylic p...

Embodiment 2

[0070] This embodiment provides a special double-sided adhesive sheet that can be peeled off again for fixing flexible printed circuit boards, such as figure 1 As shown, the double-sided adhesive sheet of this embodiment is a double-sided adhesive sheet 1 with a release liner, comprising a core material layer 32, a first adhesive layer 33 and a second adhesive layer 31, the described The core material layer 32 is disposed between the inside of the first adhesive layer 33 and the inside of the second adhesive layer 31, and also includes a first release liner 22 and a second release liner 21, the first release liner The pad 22 and the second release liner 21 are provided on the outer side of the first adhesive layer 33 and the second adhesive layer 31, respectively.

[0071] The core material of the above-mentioned core material layer is PET film, and the above-mentioned first adhesive layer includes the following components: in parts by weight, 100 parts by weight of acrylic p...

Embodiment 3

[0083] This embodiment provides a special double-sided adhesive sheet that can be peeled off again for fixing flexible printed circuit boards, such as figure 1 As shown, the double-sided adhesive sheet of this embodiment is a double-sided adhesive sheet 1 with a release liner, comprising a core material layer 32, a first adhesive layer 33 and a second adhesive layer 31, the described The core material layer 32 is disposed between the inside of the first adhesive layer 33 and the inside of the second adhesive layer 31, and also includes a first release liner 22 and a second release liner 21, the first release liner The pad 22 and the second release liner 21 are provided on the outer side of the first adhesive layer 33 and the second adhesive layer 31, respectively.

[0084] The core material of the above-mentioned core material layer is PET film, and the above-mentioned first adhesive layer includes the following components: in parts by weight, 100 parts by weight of acrylic p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com