High-temperature-resistant solvent-type acrylate pressure-sensitive adhesive and preparation method thereof

An acrylate, pressure-sensitive adhesive technology, applied in the direction of adhesive types, pressure-sensitive films/sheets, polymer adhesive additives, etc., can solve problems such as environmental pollution and depletion of valuable resources, and achieve environmental Wide range of effects with strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

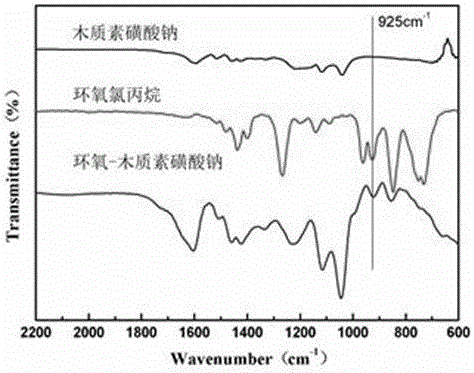

Method used

Image

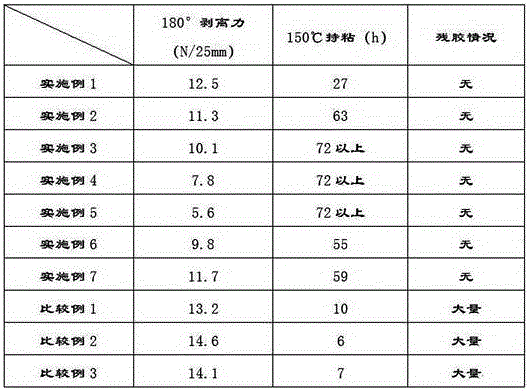

Examples

Embodiment 1

[0048] 1) Weigh 44.25g of butyl acrylate, 10.5g of isooctyl acrylate, 7.5g of methyl acrylate, 6.75g of vinyl acetate, 2.25g of maleic anhydride, 2.25g of acrylic acid, 0.75g of hydroxyethyl acrylate, epoxy modified Lignin 0.75g, ethyl acetate 53.6g, toluene 21.4g, dibenzoyl peroxide 0.225g (initiator accounts for butyl acrylate, isooctyl acrylate, methyl acrylate, vinyl acetate, maleic anhydride, acrylic acid, 0.3% of the total weight of hydroxyethyl acrylate and epoxy-modified lignin). Mix butyl acrylate, isooctyl acrylate, methyl acrylate, vinyl acetate, maleic anhydride, acrylic acid, and hydroxyethyl acrylate to obtain a monomer mixture; mix ethyl acetate and toluene to obtain a solvent. Take 22.5g of monomer mixture, 37.5g of solvent, and 0.075g of dibenzoyl peroxide and stir in a beaker evenly, then pour it into a four-necked flask equipped with a stirring device, a thermometer and a condenser, and gradually heat it to 80°C Reflux begins to appear, observe the reaction...

Embodiment 2

[0054] 1) Weigh 42.75g of butyl acrylate, 10.5g of isooctyl acrylate, 7.5g of methyl acrylate, 6.75g of vinyl acetate, 2.25g of maleic anhydride, 2.25g of acrylic acid, 0.75g of hydroxyethyl acrylate, epoxy modified 2.25g of lignin, 53.6g of ethyl acetate, 21.4g of toluene, and 0.225g of dibenzoyl peroxide. Mix butyl acrylate, isooctyl acrylate, methyl acrylate, vinyl acetate, maleic anhydride, acrylic acid, and hydroxyethyl acrylate to obtain a monomer mixture; mix ethyl acetate and toluene to obtain a solvent. Take 22.5g of monomer mixture, 37.5g of solvent, and 0.075g of dibenzoyl peroxide and stir them evenly in a beaker, then pour them into a four-necked flask equipped with a stirring device, a thermometer and a condenser, and gradually heat to 80°C to start Reflux occurs, observe the reaction system, and start timing the reaction for 1 hour when the viscosity of the system increases.

[0055] 2) After the reaction, the remaining monomer mixture, 33.75g of solvent and 0....

Embodiment 3

[0060] 1) Weigh 41.25g of butyl acrylate, 10.5g of isooctyl acrylate, 7.5g of methyl acrylate, 6.75g of vinyl acetate, 2.25g of maleic anhydride, 2.25g of acrylic acid, 0.75g of hydroxyethyl acrylate, epoxy modified 3.75g of lignin, 53.6g of ethyl acetate, 21.4g of toluene, and 0.225g of dibenzoyl peroxide. Mix butyl acrylate, isooctyl acrylate, methyl acrylate, vinyl acetate, maleic anhydride, acrylic acid, and hydroxyethyl acrylate to obtain a monomer mixture; mix ethyl acetate and toluene to obtain a solvent. Take 22.5g of monomer mixture, 37.5g of solvent, and 0.075g of dibenzoyl peroxide and stir them evenly in a beaker, then pour them into a four-necked flask equipped with a stirring device, a thermometer and a condenser, and gradually heat to 80°C to start Reflux occurs, observe the reaction system, and start timing the reaction for 1 hour when the viscosity of the system increases.

[0061] 2) After the reaction, the remaining monomer mixture, 33.75g of solvent and 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com