High-temperature-resistant mylar sheet and preparation method thereof as well as method for protecting wafer in wafer thinning process

A high-temperature-resistant, wafer-based technology, applied in chemical instruments and methods, film/sheet adhesives, semiconductor/solid-state device manufacturing, etc., can solve the problems of high wafer damage rate, poor protection effect, and affecting chip performance, etc. problems, to achieve the effect of good electrical properties, good cushioning, and excellent creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

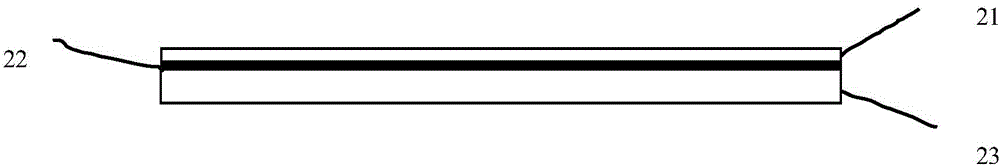

[0046] A high temperature resistant mylar sheet, comprising a PET transparent release film 21, an acrylic adhesive 22 and a PET transparent film 23, the acrylic adhesive 22 is located between the PET transparent release film 21 and the PET transparent film 23, and the PET transparent release film 21 The thickness of the PET transparent film 23 is 25 μm, and the thickness of the PET transparent film 23 is 80 μm.

[0047] In order to obtain above-mentioned high temperature resistant mylar sheet, a kind of preparation method of high temperature resistant mylar sheet, its steps are:

[0048] (a) Prepare the required dimethyl terephthalate, ethylene glycol, biaxial stretching film making machine, glue coating machine, acrylic adhesive, PET transparent release film for the preparation of high temperature resistant mylar sheets;

[0049] (b) In the 10,000-level clean environment production workshop (the air humidity in the workshop is 70%), polyethylene terephthalate is obtained thro...

Embodiment 2

[0066] Same as Example 1, the difference is: in the high temperature resistant mylar sheet, the thickness of the PET transparent release film 21 is 22 μm, and the thickness of the PET transparent film 23 is 85 μm;

[0067] A preparation method of high temperature resistant mylar sheet, the steps are the same as in Example 1, the difference is: the air humidity in the workshop in step (b) is 80%; Apply a layer of 4 μm thick acrylic adhesive evenly on the PET transparent film obtained in (b); in step (d), when the temperature drops to 30° C., stick the PET transparent release film on the acrylic adhesive.

[0068] The high temperature resistant mylar sheet prepared in this example is tested, and its performance is shown in Table 2: the adhesive force is 28g / 30mm, it is very firm and stable in adhesion to the ceramic disc, and has a long service life, and its total light transmittance is 83%, it is convenient to observe whether there are air bubbles between the high temperature r...

Embodiment 3

[0074] Same as Example 1, the difference is: in the high temperature resistant mylar sheet, the thickness of the PET transparent release film 21 is 27 μm, and the thickness of the PET transparent film 23 is 75 μm;

[0075] A preparation method of high temperature resistant mylar sheet, the steps are the same as in Example 1, the difference is: the air humidity in the workshop in step (b) is 75%; Apply a layer of 6 μm thick acrylic adhesive evenly on the PET transparent film obtained in (b); in step (d), when the temperature drops to 30° C., stick the PET transparent release film on the acrylic adhesive.

[0076] The high temperature resistant mylar sheet prepared in this example is tested, and its performance is shown in Table 3: the adhesive force is 22g / 30mm, it is very firm and stable in adhesion to the ceramic disc, and has a long service life, and its total light transmittance is 91%, it is convenient to observe whether there are air bubbles between the high temperature r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com