Camera protecting film and preparation process thereof

A technology of protective film and camera, applied in the field of camera, can solve the problems of inability to completely protect the periphery of the camera, insufficient production accuracy of the protective film, insufficient thickness of the protective film, etc., so as to save production time, maximize benefits, and form good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

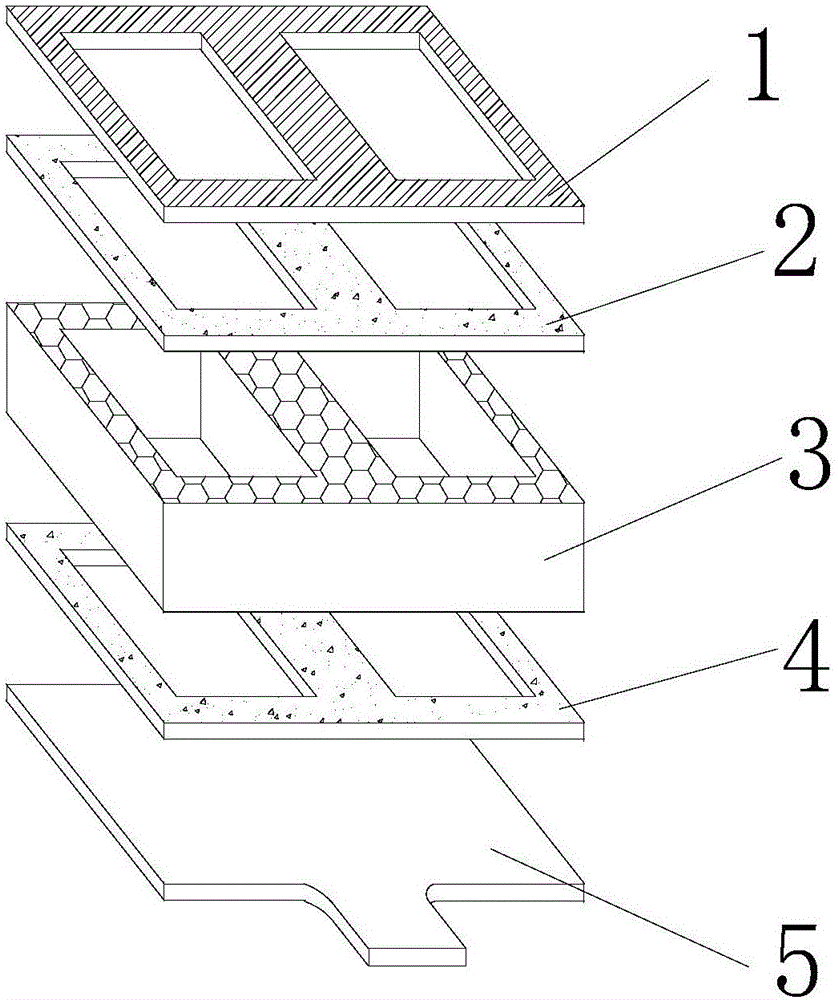

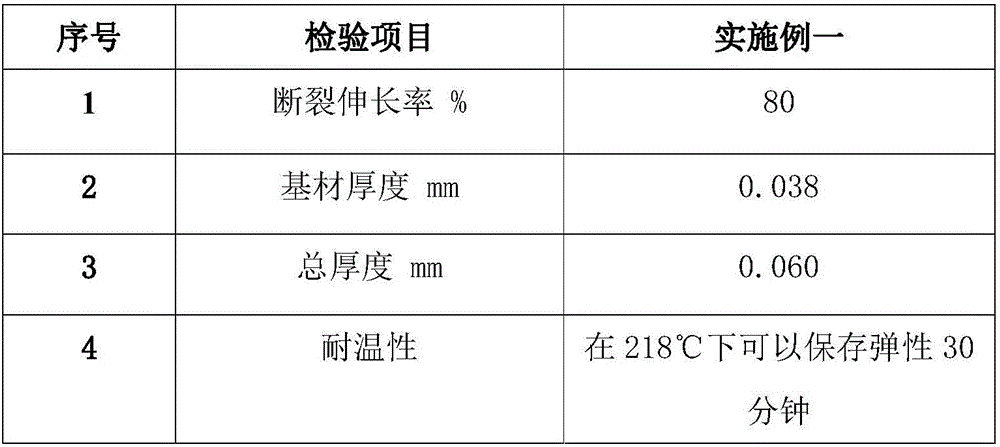

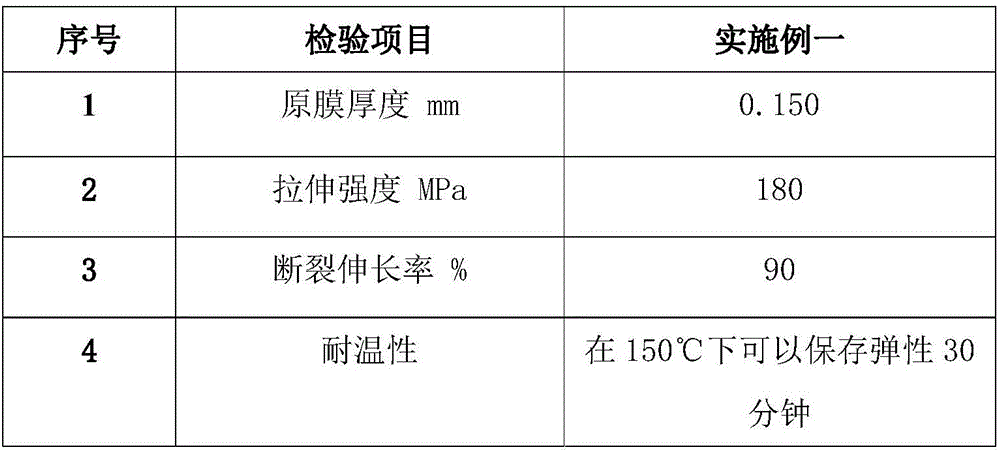

[0021] A camera protection film proposed by the present invention comprises, from top to bottom: a polyethylene protective film layer 1, an adhesive layer A2, a foam overlay layer 3, an adhesive layer B4 and a polyethylene terephthalate layer 5. , adhesive layer A2 and adhesive layer B4 are acrylic adhesive layers, polyethylene protective film layer 1, adhesive layer A2, foam overlay layer 3 and adhesive layer B4 are provided with two hollow areas of the same size, polyethylene protective A silicone adhesive layer is provided on the film layer 1, the thickness of the acrylic adhesive layer is 0.15mm, the thickness of the silicone adhesive layer is 0.02mm, and the thickness of the substrate in the polyethylene protective film layer 1 is 0.038mm. The thickness of the ethylene glycol phthalate layer 5 is 0.15 mm, and the thickness of the foam superimposed layer is 0.5 mm.

[0022] The polyethylene protective film layer 1 is PE silica gel protective film 3M851ST; the foam overlay ...

Embodiment 2

[0030] A camera protection film proposed by the present invention comprises, from top to bottom: a polyethylene protective film layer 1, an adhesive layer A2, a foam overlay layer 3, an adhesive layer B4 and a polyethylene terephthalate layer 5. , adhesive layer A2 and adhesive layer B4 are acrylic adhesive layers, polyethylene protective film layer 1, adhesive layer A2, foam overlay layer 3 and adhesive layer B4 are provided with two hollow areas of the same size, polyethylene protective A silicone adhesive layer is provided on the film layer 1, the thickness of the acrylic adhesive layer is 0.15mm, the thickness of the silicone adhesive layer is 0.02mm, and the thickness of the substrate in the polyethylene protective film layer 1 is 0.038mm. The thickness of the ethylene glycol phthalate layer 5 is 0.15 mm, and the thickness of the foam superimposed layer is 1.0 mm.

[0031] Among them, polyethylene protective film layer 1 is PE silica gel protective film 3M851ST; foam over...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com