Degradable self-adhesive film material as well as preparation method and application thereof

A self-adhesive, self-adhesive layer technology, applied in the direction of adhesives, wax adhesives, adhesive types, etc., can solve the problems of pollution, difficult to recycle, and the shape is not fixed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

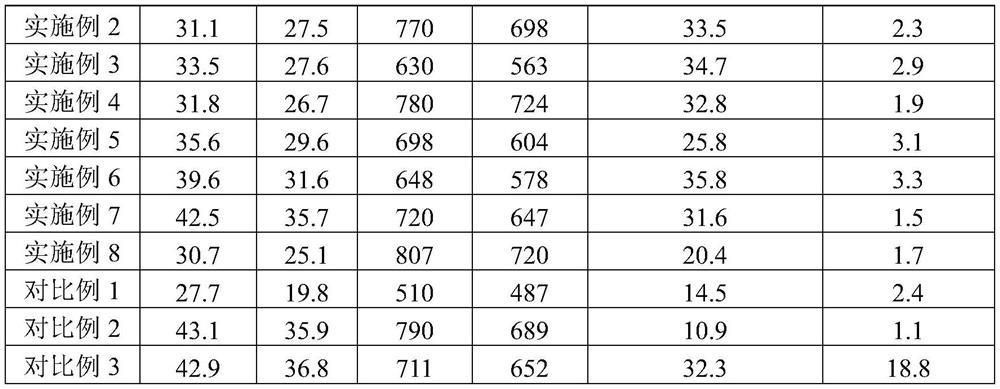

Examples

Embodiment 1

[0060] Add the raw materials for the preparation of the surface layer of the self-adhesive film into a high-speed mixer and mix them thoroughly. After mixing evenly, transfer them to a twin-screw extruder for melt extrusion and granulation to obtain a modified material for the surface layer. The modified material for the surface layer is extruded and granulated The screw temperature is 180-210° C., and the screw speed is 350 rpm.

[0061] Add the raw materials for the preparation of the self-adhesive film and self-adhesive layer into a high-speed mixer and mix them thoroughly. The temperature of the screw is 180-200°C and the rotational speed of the screw is 300rpm when extruding and granulating the raw material.

[0062] The self-adhesive film is processed by a two-layer co-extrusion blown film machine. According to the film thickness ratio, the surface layer modifier is added to the surface layer hopper, and the self-adhesive layer modifier is added to the self-adhesive laye...

Embodiment 2

[0080] The degradable self-adhesive film was prepared according to the film thickness and process method of Example 1, the difference lies in the raw material composition of the surface layer of the self-adhesive film and the self-adhesive layer.

[0081] The parts by weight of each component of self-adhesive film surface layer are as follows:

[0082]PLA (from Nature Works, model: 4032D, MI=7g / 10min 210°C, 2.16kg): 31.1 parts

[0083] PBAT (from Tunhe, Lanshan, model: TH801T, MI=4g / 10min 190°C, 2.16kg): 67 parts

[0084] Erucamide: 0.5 parts

[0085] Compatibilizer PLA-g-MAH (MI is 8.2g / 10min, 2.16kg at 190°C): 1 part

[0086] Chain extender (from BASF ADR 4370F, France, with 9 epoxy functional groups): 0.1 parts

[0087] Antioxidant 1010: 0.1 parts

[0088] Antioxidant 168: 0.2 parts.

[0089] The parts by weight of each component of the self-adhesive film self-adhesive layer are as follows:

[0090] PLA (from Nature Works, model: 4032D, MI=7g / 10min 210°C, 2.16kg): 29....

Embodiment 3

[0098] The degradable self-adhesive film was prepared according to the film thickness and process method of Example 1, the difference lies in the raw material composition of the surface layer of the self-adhesive film and the self-adhesive layer.

[0099] The parts by weight of each component of self-adhesive film surface layer are as follows:

[0100] PLA (from Nature Works, model: 4043D, MI=16g / 10min 210°C, 2.16kg): 35 parts

[0101] PBS (from Tunhe, Lanshan, model: TH803S, MI=18g / 10min 190°C, 2.16kg): 63.1 parts

[0102] Oleic acid amide: 0.5 parts

[0103] Compatibilizer PLA-g-MAH (MI is 6.5g / 10min, 190°C 2.16kg): 1 part

[0104] Chain extender (from BASF ADR 4468, France, with 5 epoxy functional groups): 0.1 parts

[0105] Antioxidant 1010: 0.1 parts

[0106] Antioxidant 168: 0.2 parts.

[0107] The parts by weight of each component of the self-adhesive film self-adhesive layer are as follows:

[0108] PLA (from Nature Works, model: 4043D, MI=16g / 10min 210°C, 2.16kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com