Conductive adhesive

A technology of conductive adhesives and adhesives, applied in the field of adhesives and conductive adhesives, can solve the problems of electronic components without solving the bonding area, achieve enhanced bonding performance, expand the scope of use, and facilitate batches The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Preparation of conductive adhesives for bonding copper to gold conductive tape. The size of the copper material is 0.5mm×0.5mm×0.25mm.

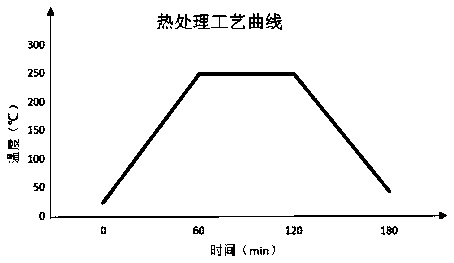

[0024] Diethylene glycol and cyanate resin are used as a mixed solvent system, and a uniform organic mixed solvent is formed by sufficient stirring, and the proportion of the two is 2:3; silver powder with a purity of 99.95% is selected, and the balls are milled into micro-nano scale through high-energy ball milling Silver powder, and then select sample sieves with different meshes to sort out the A-type silver particles with a diameter of 3-20 μm and the B-type silver particles with a diameter of 200 nm or less. Pour into the prepared mixed organic solvent; then add 2-cyclohexyl acrylate particles as a dispersant, the particle size is less than 20μm. Then a double planetary power mixer was used for mixing and infiltration, and finally the prepared conductive adhesive was placed in a -40°C refrigerator for storage for later use. In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com