Method for preparing TZ-PSBSR soldering rubber blended waterproof coiled material

A waterproof membrane and thermal welding technology, which is applied in the field of building waterproof materials, can solve problems such as easy cracking, failure to form a waterproof layer, and affect the waterproof effect of the membrane, and achieve the effect of solving the bonding problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

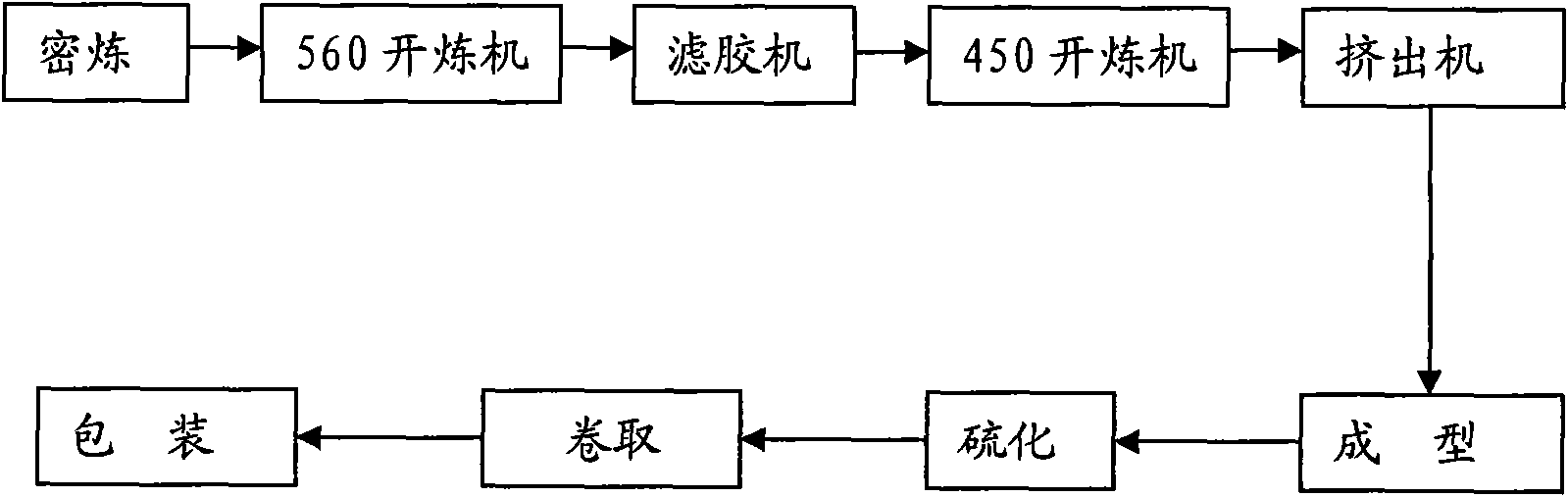

[0007] A preparation method of TZ-PSBSR thermally welded rubber-plastic blended waterproof membrane, which is composed of POE (7380), styrene-butadiene rubber (1502), SBS (1401), light calcium carbonate, carbon black N330, modifier TP -10, DOP, sulfur, antioxidant RD, TMTD, antioxidant 4010, POE (7380), styrene-butadiene rubber (1502), SBS (1401), light calcium carbonate, carbon black N330, modifier TP-10 , DOP, sulfur, anti-aging agent RD, TMTD, anti-aging agent 4010 weight ratio is 100: 100: 100: 320: 65: 2: 15: 3: 5: 5: 2.5, all raw materials are added to the banburying according to the formula ratio , the banburying time is 9min, and the banburying temperature is 130-150°C, so that it can be mixed evenly and then discharged. The glue is poured on the 560 open mill, the temperature is lowered to ≤90°C, and then the strips are unloaded. The impurities are filtered through the filter rubber machine, and the strips are thinned and mixed on the 450 open mill. After the mixing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com