Injection molding suspension

A technology of injection molding and injection molding, applied to springs, springs/shock absorbers, mechanical equipment, etc. made of plastic materials, can solve problems such as pollution, easy to fly, and environmental pollution, and achieve the effect of optimizing the suspension structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

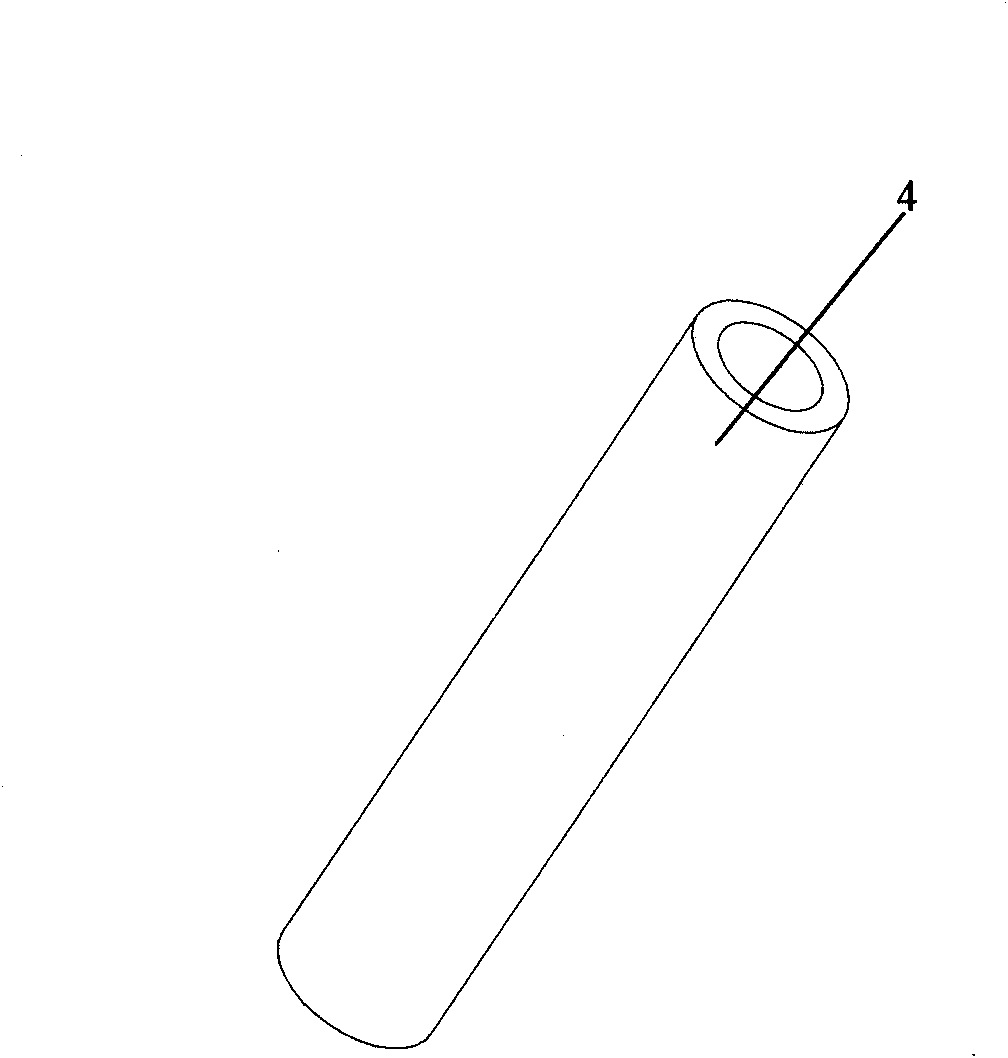

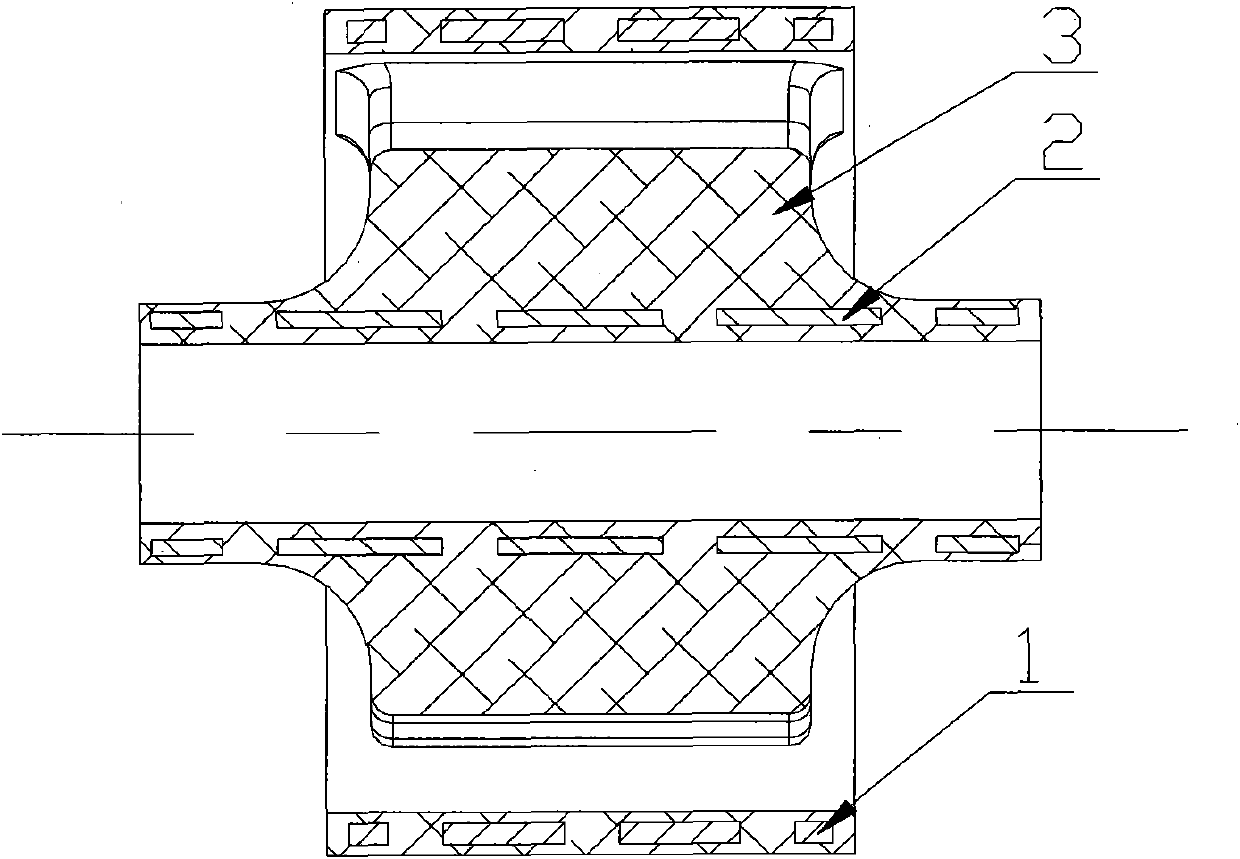

[0017] The present invention provides an injection molding mount, in which a thermoplastic elastomer 3, a metal outer liner 1 and a metal inner liner 2 are molded into such figure 1 In the injection molded body shown, the thermoplastic elastomer 3 is located between the metal outer lining pipe 1 and the metal inner lining pipe 2, and is connected to the metal outer lining pipe 1 and the metal inner lining pipe 2 respectively.

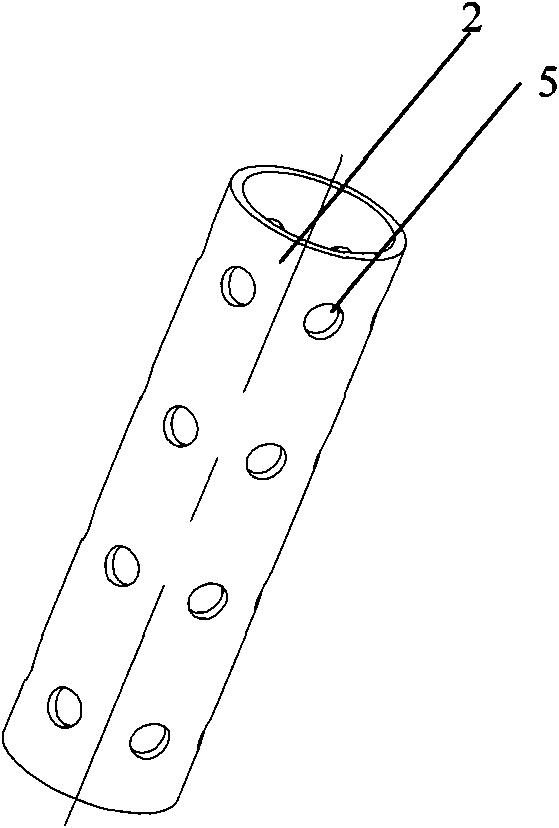

[0018] Another example figure 2 As shown, the metal inner tube 4 is pressed into the metal inner tube 2 so that the metal inner tube 4 and the metal inner tube 2 are in an interference fit.

[0019] Wherein, the structure of the metal outer lining pipe 1 and the metal inner lining pipe 2 is as follows: image 3 and Figure 4 As shown, through holes 5 are evenly distributed on its surface respectively, and the number of through holes 5 can be between 10-50. In this embodiment, the number is 30, and the diameter of through holes 5 is between 2-5mm. An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com