A kind of halogen-free flame-retardant two-component polyurethane adhesive for rail passenger cars and its preparation method

A two-component polyurethane, rail passenger car technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of body structure bonding, etc. The effect of high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

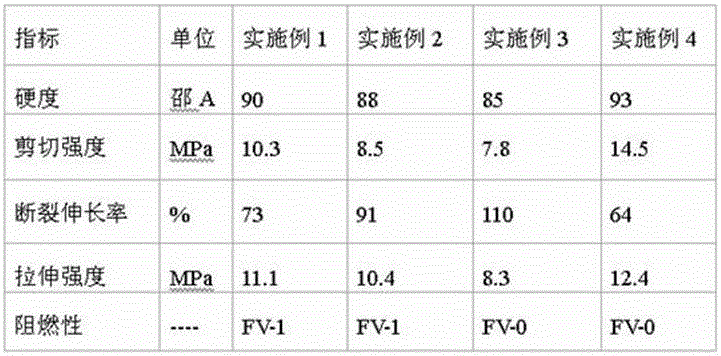

Examples

Embodiment 1

[0020] Add castor oil polyol 13.2% Wt, polyester polyol (hydroxyl value 167mgKOH / g, molecular weight 1000) 12.2%Wt, bisphenol A polyether polyol (hydroxyl value 270mgKOH / g, molecular weight 450) 5.4% Wt, flame retardant plasticizer dimethyl phosphate 11.4% Wt, heated to 120 ° C, and dehydrated under vacuum for 2 hours, then cooled to 60 ° C, added to the planetary mixer, Then add 57.0% Wt of aluminum hydroxide, 0.58% Wt of epoxy-terminated silane coupling agent, and 0.25% Wt of organometallic catalyst, stir for 2 hours in a vacuum state, and discharge, which is A component. Component B is liquefied polymethylene polyphenyl polyisocyanate. According to A׃B=6׃1 (mass ratio), it can be used after being fully mixed.

Embodiment 2

[0022] Add castor oil polyol 19.4% Wt, polyester polyol (hydroxyl value 120mgKOH / g, molecular weight 1540) 21.5%Wt, bisphenol A polyether polyol (hydroxyl value 200mgKOH / g, molecular weight 658) into the three-necked flask ) 6.5% Wt, flame retardant plasticizer ethyl diethyl phosphate 8.6% Wt, heated to 120 ° C, and dehydrated under vacuum for 2 hours, then cooled to 60 ° C, added to the planetary mixer, and then Add 21.5% Wt of magnesium hydroxide, 21.5% Wt of aluminum hydroxide, 0.7% Wt of epoxy-terminated silane coupling agent, 0.3% Wt of organometallic catalyst, etc., stir for 2 hours in a vacuum state, and discharge the material, which is component A . Component B is a mixture of liquefied diphenylmethane diisocyanate 50%wt and diphenylmethane diisocyanate 50%wt. According to A׃B=6׃1 (mass ratio), it can be used after being fully mixed.

Embodiment 3

[0024] Add castor oil polyol 20.8%Wt, polyester polyol (hydroxyl value 76mgKOH / g, molecular weight 2000) 10.4%Wt, bisphenol A polyether polyol (hydroxyl value 270mgKOH / g, molecular weight 450) 10.4% Wt, flame retardant plasticizer triisopropylphenyl phosphate 12.7% Wt, heated to 120°C, dehydrated under vacuum for 2 hours, then cooled to 60°C, added to planetary mixer , then add 44.8% Wt of magnesium hydroxide, 0.9% Wt of epoxy-terminated silane coupling agent, 0.1% Wt of organometallic catalyst, etc., stir for 2 hours in a vacuum state, and discharge, which is A component. Component B is a mixture of 50% wt of polymethylene polyphenyl polyisocyanate and 50% wt of liquefied diphenylmethane diisocyanate. According to A׃B=6׃1 (mass ratio), it can be used after being fully mixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com