Small sample sizing machine

A kind of sizing machine, yarn technology, applied in the direction of liquid/gas/vapor yarn/filament processing, etc., can solve the problems of yarn bonding, incomplete drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

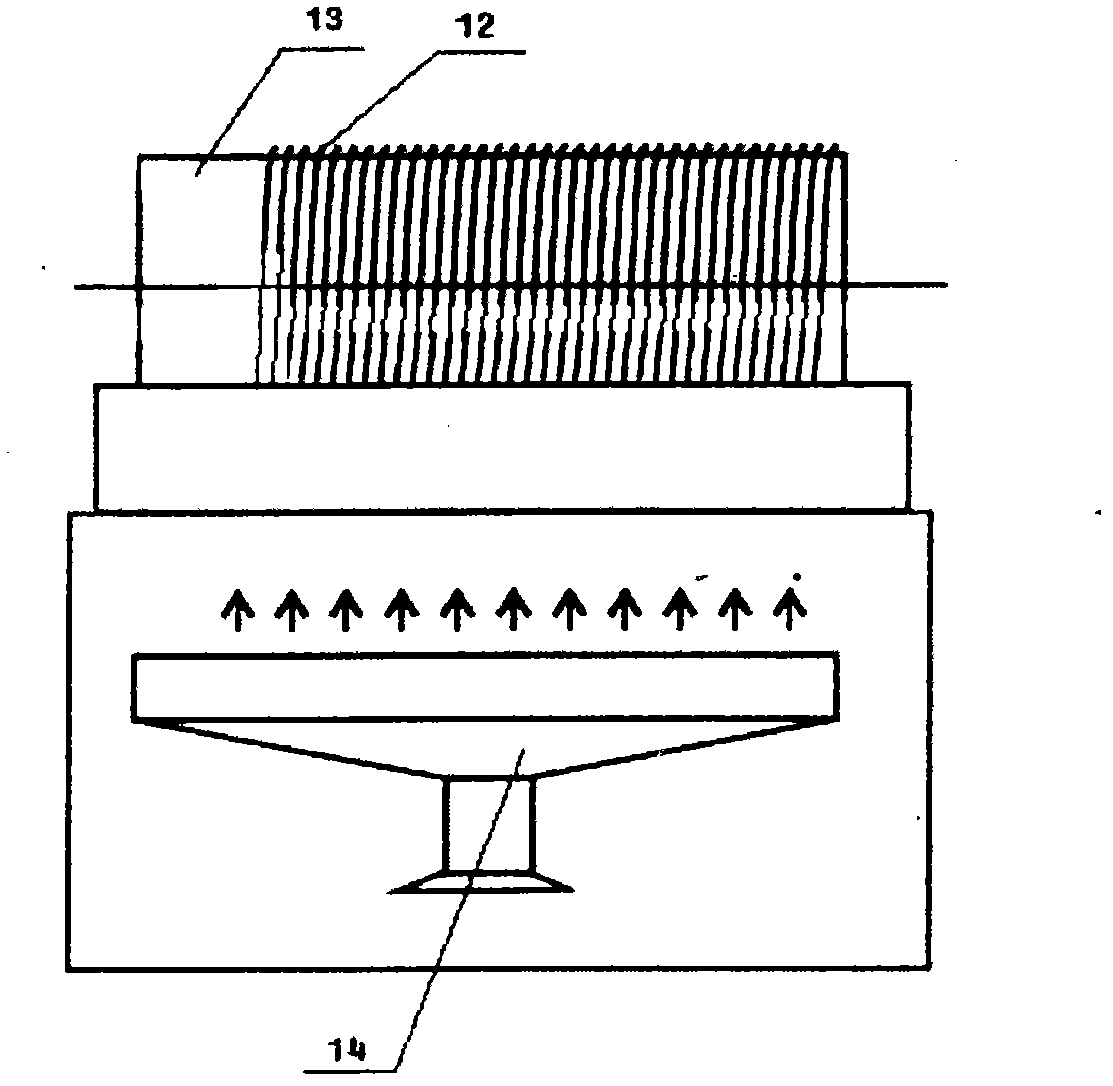

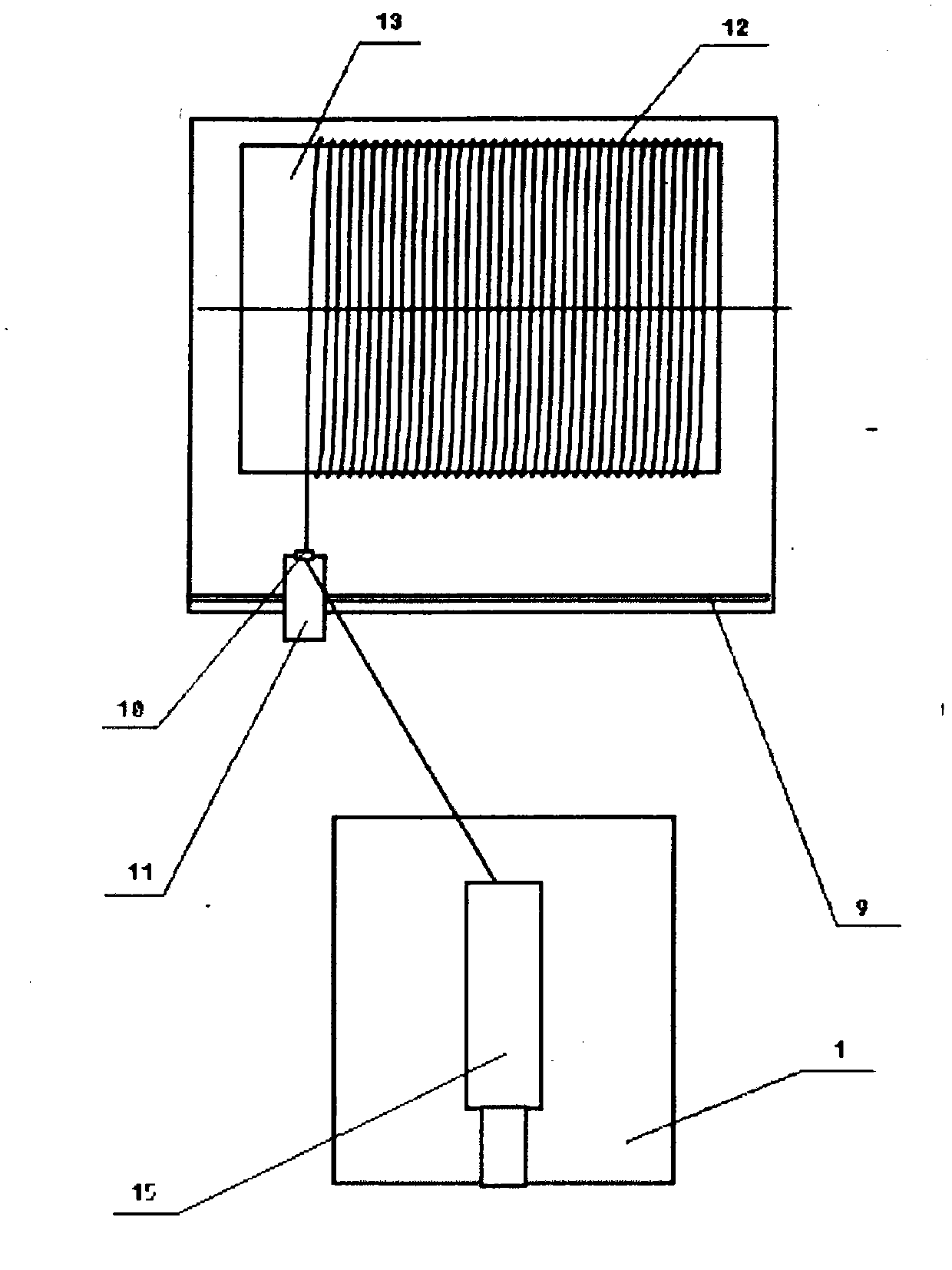

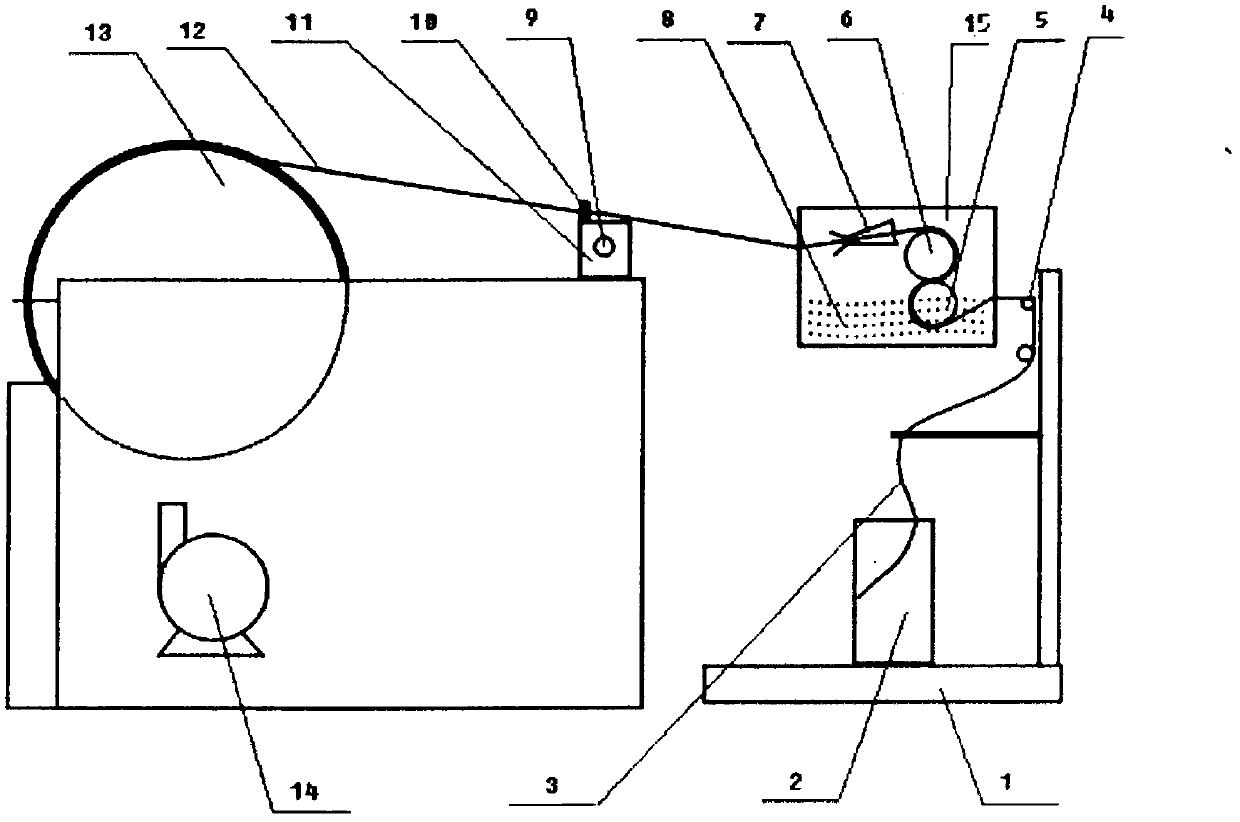

[0009] Referring to the accompanying drawings, the yarn bobbin 2 of the present embodiment is placed on the creel 1, the yarn 3 is unwound from the yarn bobbin 2, the yarn 3 enters the sizing tank 15 through the guide wheel 4, and the bottom of the sizing tank 15 is equipped with a Material 8, yarn 3 walks around press roll 5, and squeegee roll 6 enters squeegee 7, and the bottom of press roll 5 is immersed in the slurry 8, makes the yarn 3 that walks around press roll 5 from the slurry After the process, the yarn 3 becomes the sizing yarn 12 after being covered with sizing, and the squeegee 7 scrapes off the excess sizing on the sizing yarn 12, and the screw mandrel 9 is installed on the frame and can rotate to guide the yarn. The device base 11 is installed on the screw mandrel, and the rotation of the screw mandrel 9 drives the yarn guide base 11 to reciprocate along the screw mandrel 9, and the yarn guide 10 is installed on the yarn guide base 11, so that the yarn guide 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com