Heat-vulcanization adhesive for adhering ceramics with elastomer

A technology of thermal vulcanization rubber and elastomer, which is applied in the direction of adhesive types, polymer adhesive additives, halogen rubber derivative adhesives, etc., and can solve problems such as difficult high-hardness and high-strength ceramic bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

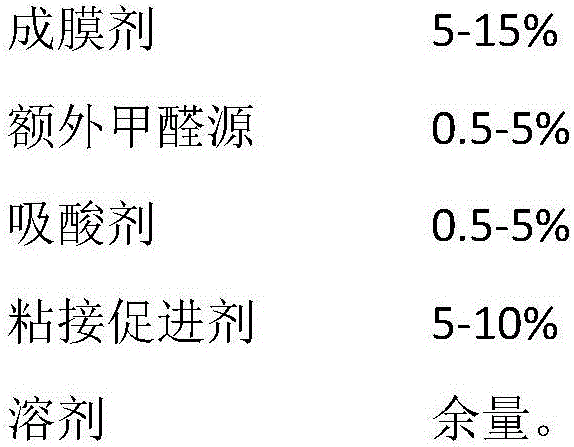

Method used

Image

Examples

Embodiment Construction

[0037] The foregoing description and the following examples are intended to disclose and illustrate the present invention, and the specific amounts and combinations of the ingredients described herein are not intended to limit the scope of the present invention defined by the claims.

[0038] (1) Adhesion promoter

[0039]

[0040] Prepare the silane-modified inorganic porous material supported phenolic compound according to the following steps:

[0041] Soak the porous inorganic filler in 30wt% N-β-(aminoethyl)-γaminopropyltrimethoxysilane / acetone solution at 70°C for 4 hours, filter and dry and soak in 20wt% trimethylol at 50°C Base phenol / toluene solvent for 2 hours, after drying, the adhesion promoter can be obtained.

[0042] The formula number corresponding to the adhesion promoter is as follows:

[0043] serial number 1 2 3 Adhesion Promoter Ad.1 Ad.2 Ad.3

[0044] The prepared silane-modified inorganic porous material supporting phenoli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com