Preparation process of carbon/ceramic-graphite composite material and carbon/ceramic-graphite composite material prepared through preparation process

A ceramic composite material and composite material technology, which are applied in the field of composite materials composed of carbon/ceramic materials and graphite and their products, can solve problems such as crystallizer loss, increase in product quality, affecting production efficiency of production lines, etc., to achieve excellent strength, improve The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

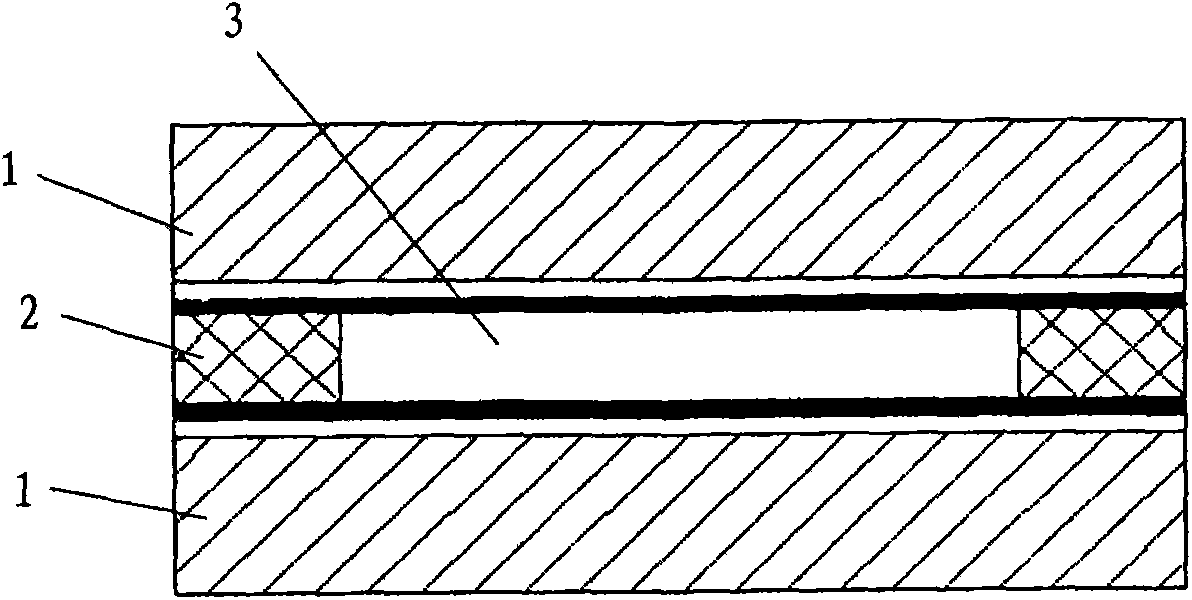

[0021] See figure 1 , the specific implementation of the present invention is given below, and it should be noted that the specific description of the implementation examples should not be regarded as limiting the protection scope of the present invention.

[0022] The specific implementation example of the present invention is: on the substrate of the graphite plate, the coupling layer is bonded sequentially, and then the carbon / ceramic composite reinforcement layer is bonded, followed by hot pressing, carbonization, vapor deposition, and finally sintering at high temperature. The thickness of the graphite matrix of the carbon / ceramic composite material is 20-30mm, the thickness of the coupling layer is 3-5mm, and the thickness of the reinforced layer of the carbon / ceramic composite material is 1.5-2.5mm.

[0023] Due to the high thermal conductivity of graphite materials, the overall thermal conductivity of the three-layer composite material can still maintain a high level, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com