Rotor homopolarity magnetic steel bonding and positioning device

A positioning device and a technology of the same polarity, which is applied in the direction of electromechanical devices, manufacture of stator/rotor body, manufacture of motor generators, etc., can solve problems such as the inability to achieve magnetic steel bonding on the outer surface of the rotor, and achieve improved assembly speed and assembly High precision, improved processing efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is further described below in conjunction with the accompanying drawings of the embodiments, but the scope of protection is not limited to the description.

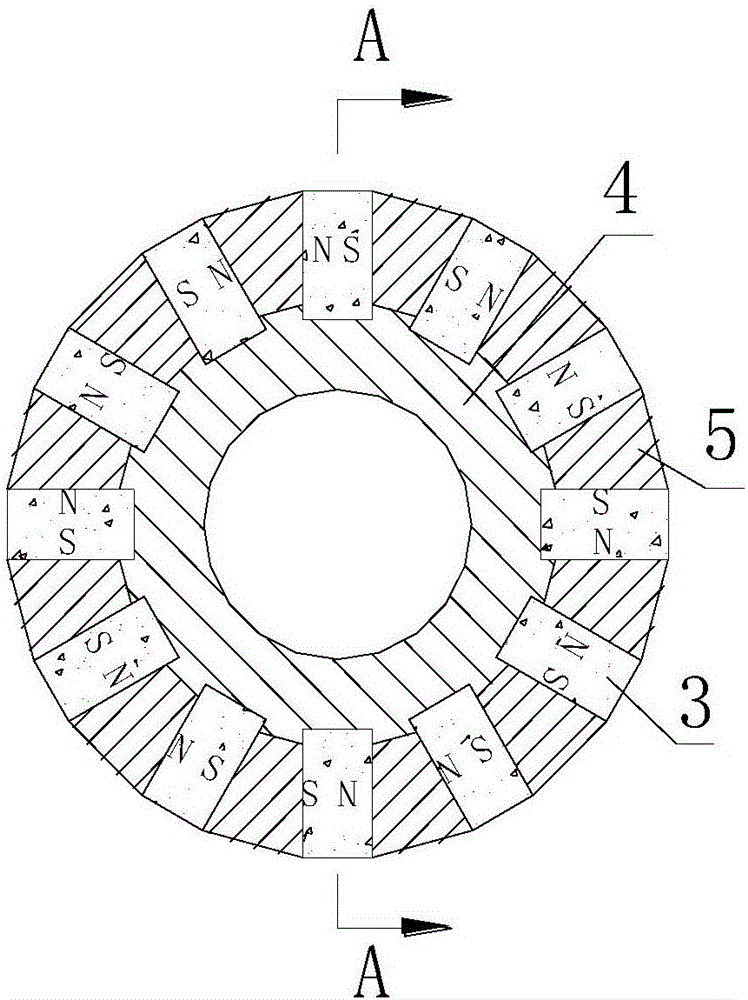

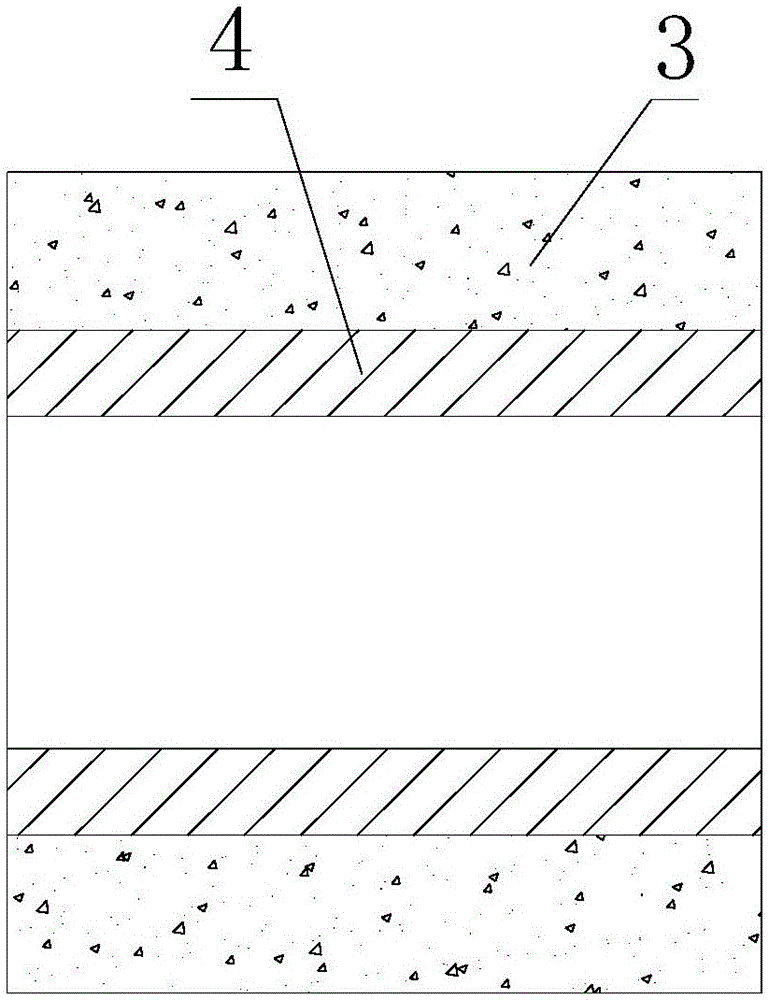

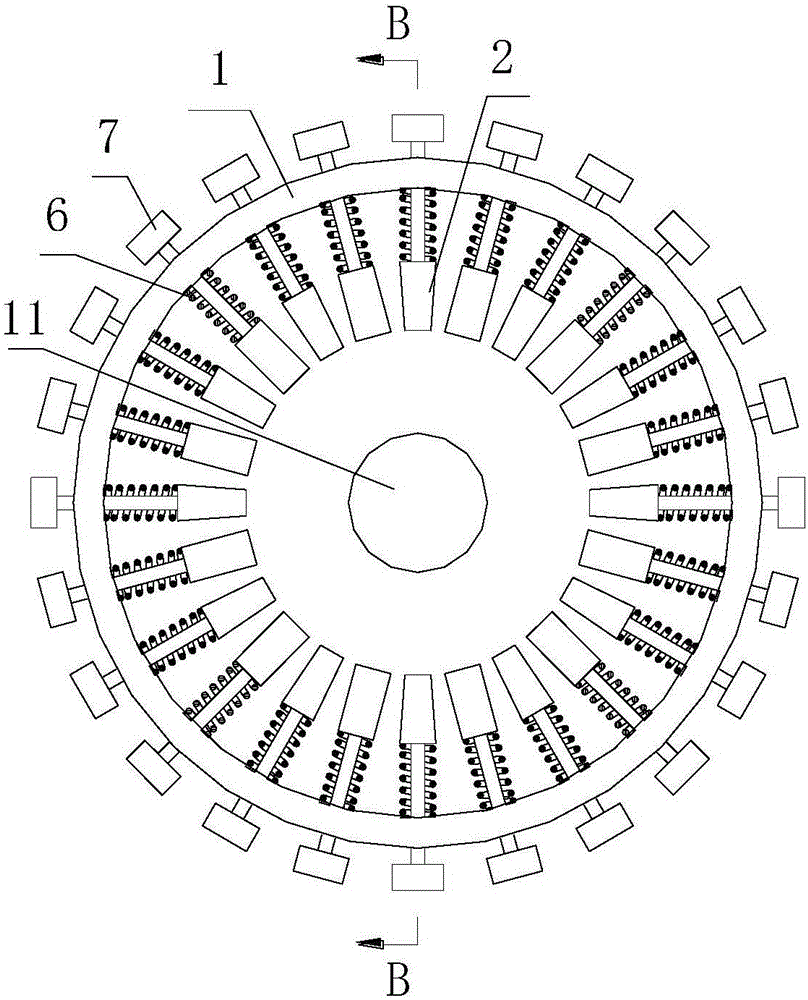

[0032] Such as image 3 , Figure 4 As shown, a magnetic steel bonding positioning device with the same polarity of the rotor includes a positioning sleeve 1 and a number of elastic components uniformly arranged along the circumferential direction of the positioning sleeve 1. The elastic components are composed of screws 7, tightening blocks 2 and springs 6 , the fastening block 2 is located inside the positioning sleeve 1 and connected to the end of the screw 7, the spring 6 is set on the screw 7, and is located between the fastening block 2 and the positioning sleeve 1, and the center of the positioning sleeve 1 A positioning boss 11 is also provided. Using this positioning device, when bonding the rotor magnetic steel, if Figure 9 , Figure 10 As shown, put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com