High-water-resistance primer for silane modified building sealant

A silane modification and sealant technology, applied in the field of materials, can solve the problems of poor water resistance and hydrolysis resistance, high polarity of silicone resin, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086]

[0087]

[0088] Concrete selection and mass percent of each component in table 1 embodiment 1

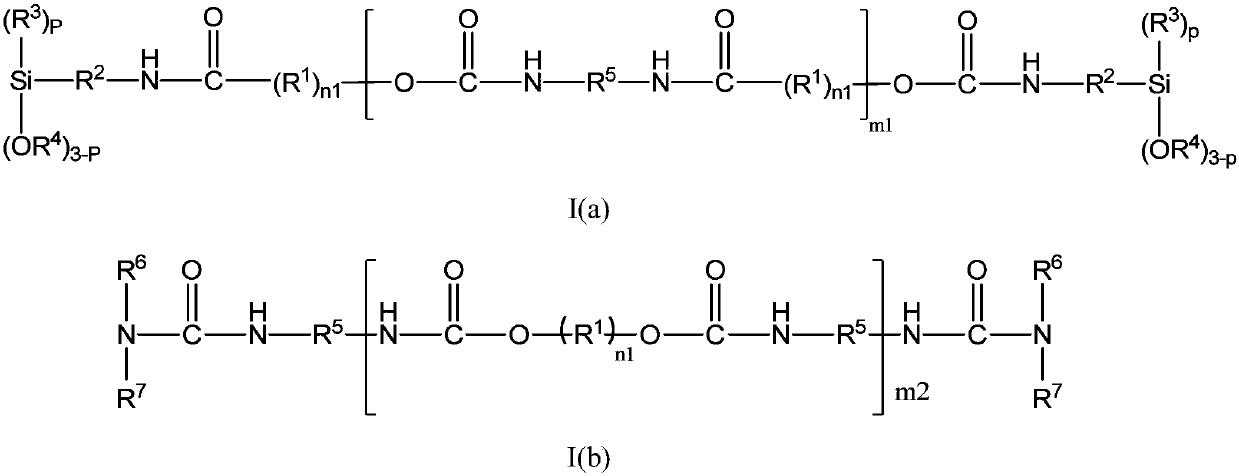

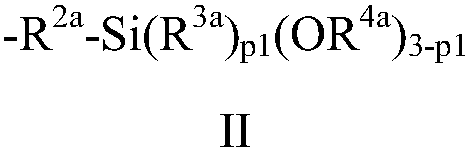

[0089] In this embodiment 1, the silane-modified polymer (A) is a silane-terminated polybutadiene of formula I(a), that is, in the structural formula of formula I(a), m1=0, R 2 for -CH 2 CH 2 CH 2 -, p=0, R 4 for -CH3;

[0090] R in Formula III a , R b , R c , R d , R e and R f Both are H atoms, the range of x1+x2 is 10% to 60%, the range of x3 is 40% to 90%; x4=0; the unit structure of which the molar content is x3 – CH2-CH=CH-CH2-, has The following two isomeric forms:

[0091]

[0092] Specifically in the present embodiment, select the product of commercially available Evonik for use EP ST-M is a silane-modified polymer (A), which is trimethoxysiloxane-terminated polybutadiene with a number-average molecular weight of 3500 g / mol and an average functionality of siloxane of 6.9 to 7.2.

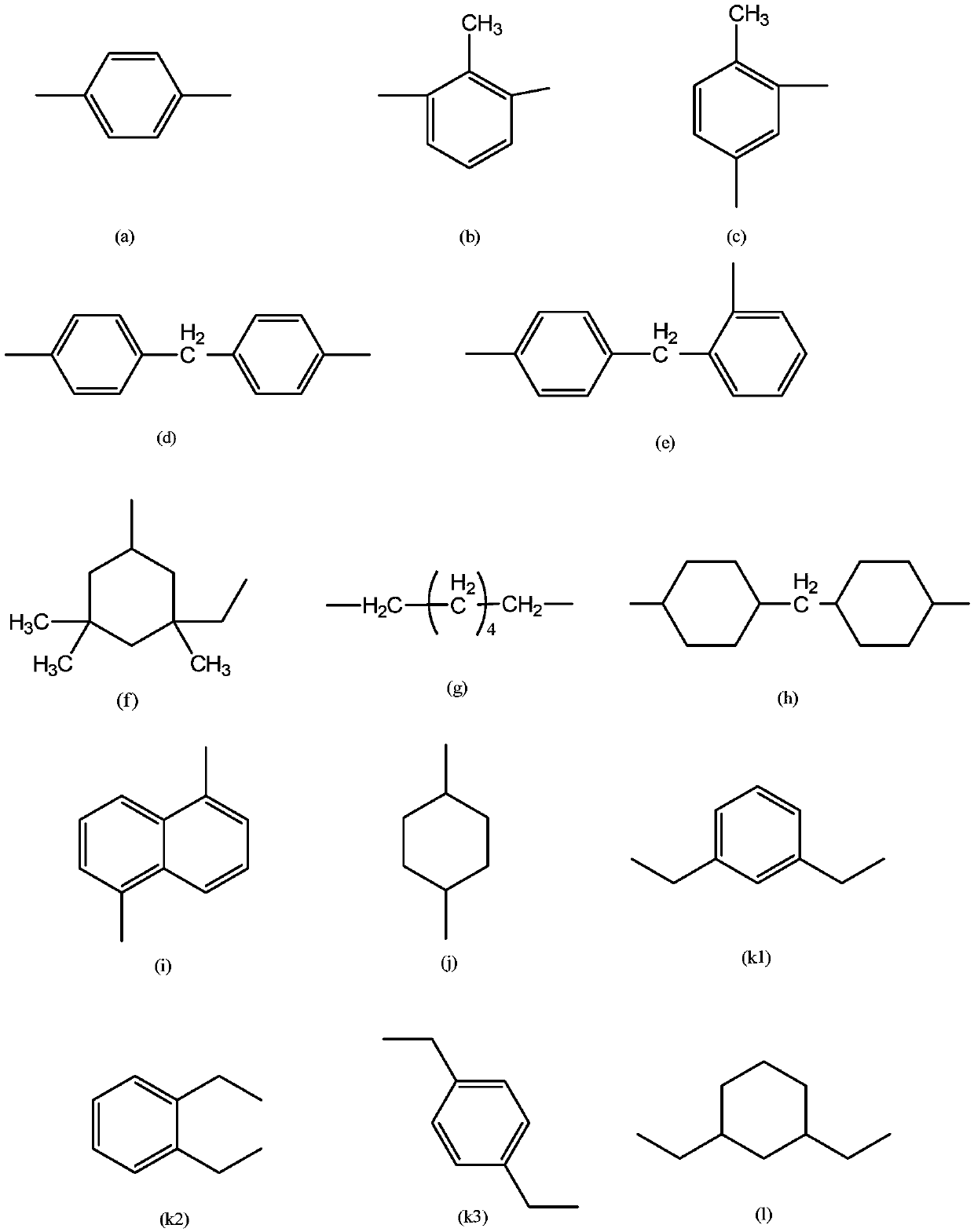

[0093] The cross-linking agent (B) has a polysiloxane polymer o...

Embodiment 2

[0098]

[0099] Concrete selection and mass percent of each component in table 2 embodiment 2

[0100] Same as in Example 1, the silane-modified polymer (A) is a silane-terminated polybutadiene of formula I(a) EP ST-M. 1146 is a commercial product of EVONIK, which is an oligomer copolymerized with aminosilane and alkylsilane, and is used as the silane coupling agent (C) in this embodiment.

[0101] The preparation steps are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0103]

[0104]

[0105] Concrete selection and mass percent of each component in table 3 embodiment 3

[0106] In this embodiment 3, the silane-modified polymer (A) is a silane-modified polyisoprene of formula I(b), and the preparation method is: using hydroxyl-terminated isoprene (1,2 addition structure is Mainly, the molecular weight is 30000,) using hydroxyl-terminated polybutadiene (POLY R-15, commercially available from CRAY VALLEY in the United States, obtained by free radical polymerization, with a number average molecular weight of 2500 to 2800 mol / g, and an average hydroxyl group functionality of 2.2 to 2.6) was mixed at a mass ratio of 1:1 and heated to 110°C And vacuum stirring and dehydration for 2h, and cooling to room temperature, the mixture of the obtained hydroxyl-terminated polybutadiene and hydroxyl-terminated polyisoprene is used as a raw material, firstly mixed with TDI (toluene diisocyanate, commercially available Commercially available) was reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com