Moisture-curing liquid waterproofing composition for free-smashing bricks suitable for joint pretreatment and repair

A pretreatment, moisture curing technology, applied in the field of materials, can solve the problems of poor durability, curing, incomplete curing, etc., and achieve the effects of excellent bonding compatibility, good water resistance, and extended durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

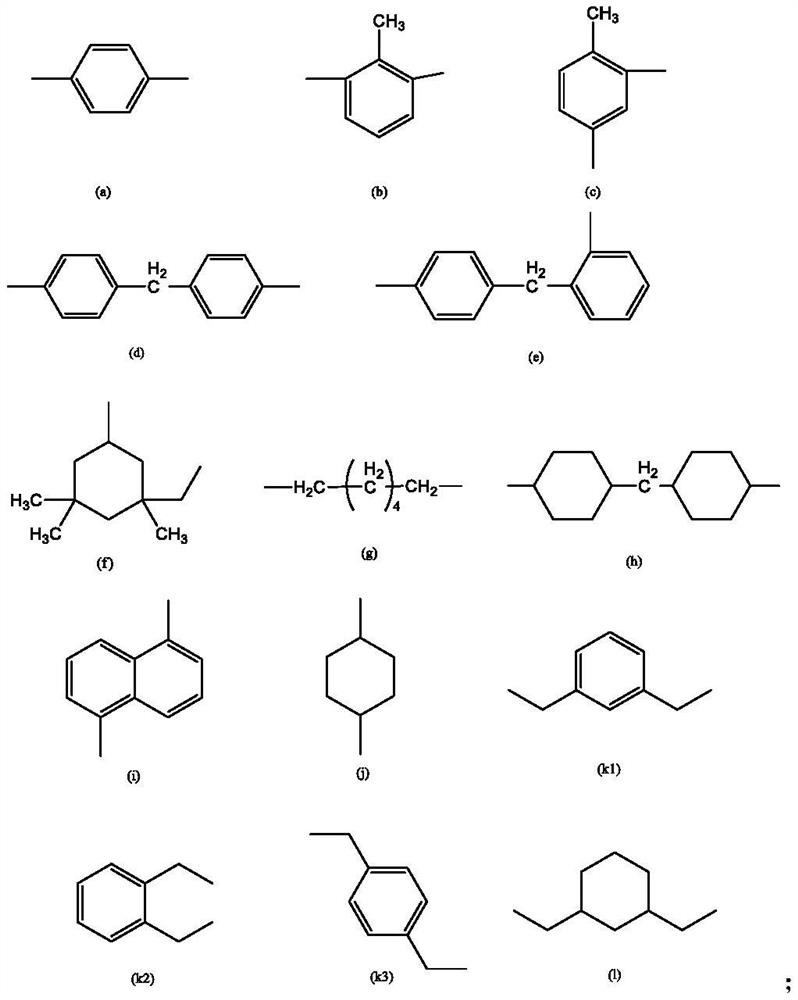

Method used

Image

Examples

Embodiment 1

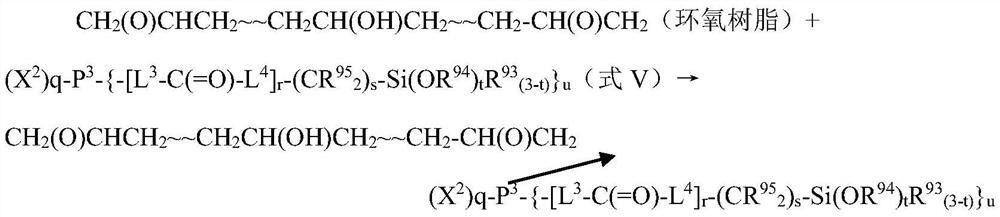

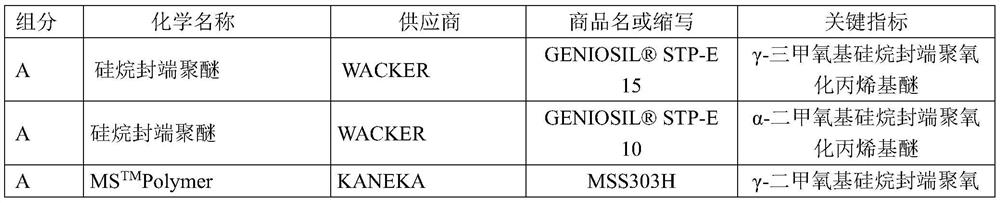

[0152] Example 1: Self-made alkoxy-silicon-modified polymer A1 with a chain segment formed from the condensation reaction of epichlorohydrin with active hydrogen-containing compounds such as alcohols, phenols, acids or amines as the main chain

[0153]In this example, self-made alkoxy-silicon modified polymer A1, which is formed by the condensation reaction of epichlorohydrin with active hydrogen-containing compounds such as alcohols, phenols, acids, or amines, is the main chain: The aminoalkoxysilane of the group carries out ring-opening reaction with the above-mentioned epoxy resin to bind the alkoxysilane to the epoxy resin, and the epoxy resin selects bisphenol A glycidyl ether type epoxy resin E51 (NPEL-128 ), alkoxysilanes containing active hydrogen groups are selected (C 6 h 5 )NH-(CH2)3-Si(OCH 3 ) 3 , that is, the secondary aminosiloxane of γ-anilinopropyl trimethoxysilane, according to the equimolar ratio of -CH(O)CH2 and NH, react to obtain viscous epichlorohydrin...

Embodiment 2

[0155] Example 2: Self-made alkoxy silicon-modified polymer A1 with a chain segment formed from the condensation reaction of epichlorohydrin with active hydrogen-containing compounds such as alcohols, phenols, acids or amines as the main chain

[0156] (1) Equipped with a dropping funnel (connected to vacuum during distillation), reflux water condenser (connected to N during atmosphere protection) 2 ), a stirrer and a thermometer in a four-necked flask; polytetramethylene ether glycol (PTMEG 2000, molecular weight 2000, a primary hydroxyl-terminated homopolymer obtained by monomer tetrahydrofuran ring-opening polymerization), optional Select commercially available BASF products 2000 as a raw material, first remove water under reduced pressure at 110 °C, and 2 Cool to room temperature under protection for use. In a four-necked flask, react with IPDI (commercially available) for 3 hours under nitrogen protection at 70-80°C, and prepare isocyanate-blocked Terminated polytetram...

Embodiment 3

[0159] Example 3: Self-made alkoxy silicon-modified polymer A1 with a chain segment formed by the condensation reaction of epichlorohydrin with an active hydrogen-containing compound such as alcohol, phenol, acid or amine as the main chain

[0160] The alkoxysilane is bonded to the epoxy resin through the ring-opening reaction between the mercaptoalkoxysilane with active hydrogen groups and the above epoxy resin. The epoxy resin is bisphenol A glycidyl ether type epoxy resin E51 (NPEL-128), the alkoxysilane containing active hydrogen group selects HS-(CH2)3-Si(OCH 3 ) 3 , that is, KH-590, which is formed by the condensation reaction of epichlorohydrin with active hydrogen-containing compounds such as alcohols, phenols, acids or amines, according to the equimolar ratio of -CH(O)CH2 and SH. The segment of the main chain is an alkoxy silicon modified polymer A1.

[0161] The specific preparation method is as follows: 1.0kg epoxy resin E51 (NPEL-128) is added to a four-necked fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com