Silane modified building sealant primer capable of quickly forming film and having high barrier property

A silane-modified, high-barrier technology, applied in the field of materials, can solve the problems of damaging the bond between sealant and concrete, loose particles, water seepage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120]

[0121]

[0122] Concrete selection and mass percent of each component in table 1 embodiment 1

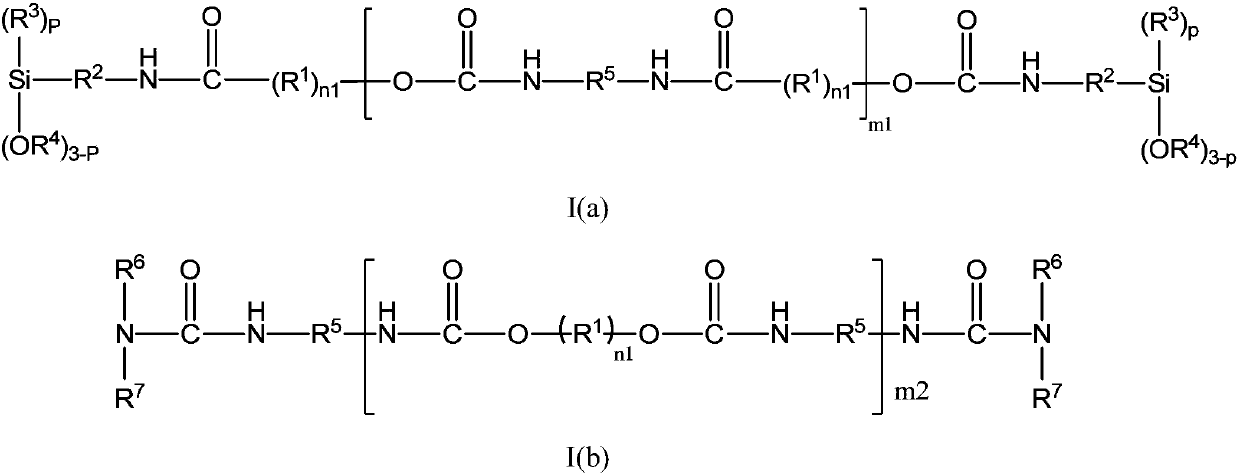

[0123] In this embodiment 1, the silane-modified polymer (A) is a silane-terminated polybutadiene of formula I(a), that is, in the structural formula of formula I(a), m1=0, R 2 for -CH 2 CH 2 CH 2 -, p=0, R 4 for -CH3;

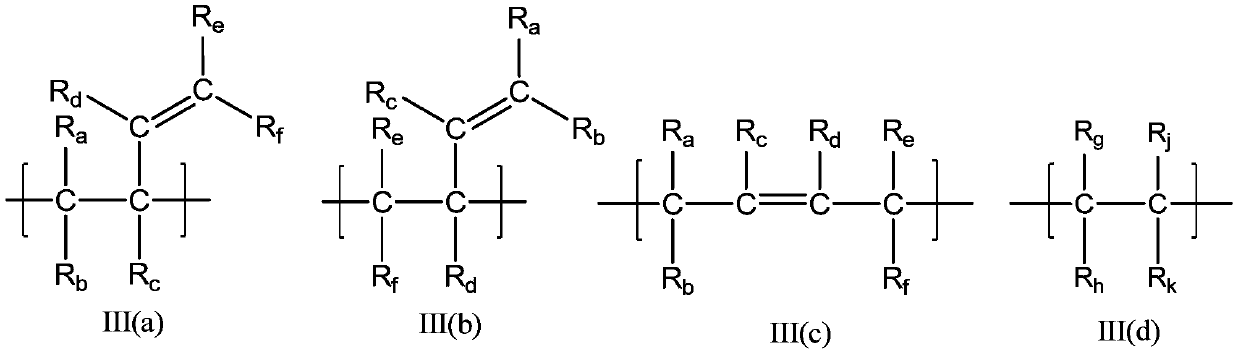

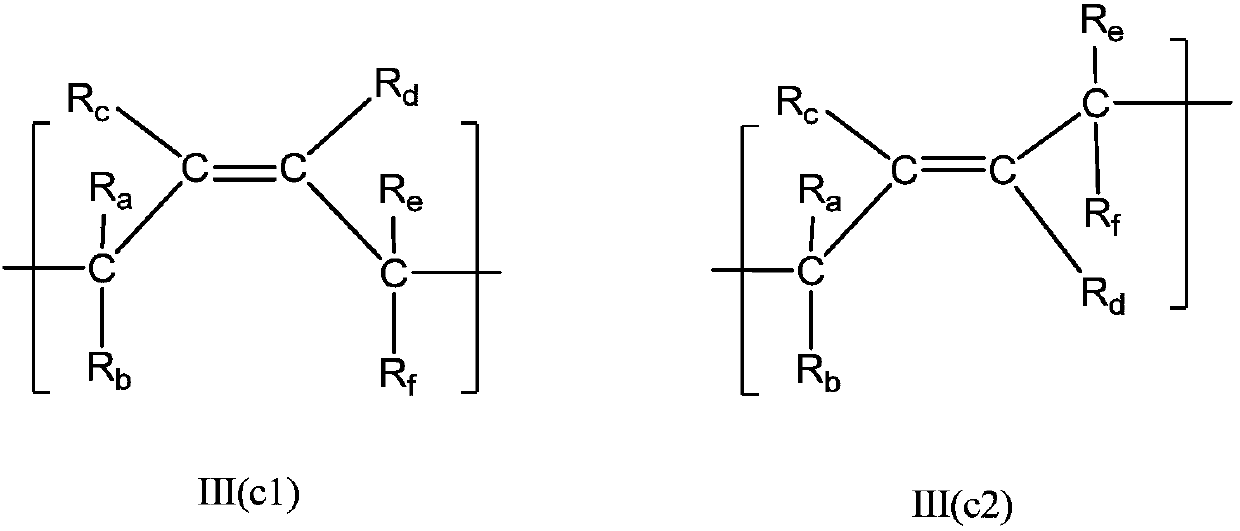

[0124] R in Formula III a , R b , R c , R d , R e and R f Both are H atoms, the range of x1+x2 is 10% to 60%, the range of x3 is 40% to 90%; x4=0; the unit structure of which the molar content is x3 – CH2-CH=CH-CH2-, has The following two isomeric forms:

[0125]

[0126] Specifically in the present embodiment, select the product of commercially available Evonik for use EP ST-M is a silane-modified polymer (A), which is trimethoxysiloxane-terminated polybutadiene with a number-average molecular weight of 3500 g / mol and an average functionality of siloxane of 6.9 to 7.2.

[0127] In this embodiment, the reactive film-forming resin (F) ...

Embodiment 2

[0130]

[0131] Concrete selection and mass percent of each component in table 2 embodiment 2

[0132] Same as in Example 1, the silane-modified polymer (A) is a silane-terminated polybutadiene of formula I(a) EP ST-M. 1146 is a commercial product of EVONIK, which is an oligomer copolymerized with aminosilane and alkylsilane, and is used as the silane coupling agent (C) in this embodiment.

[0133] The preparation method of crosslinking agent (B): 3-aminopropyltrimethoxysilane H 2 N(CH 2 ) 3 Si(OCH 3 ) 3 Mix with 3-glycidyl ether propyl trimethoxysilane (KH-560) at a molar ratio of 1:2, stir and react under nitrogen protection at 70°C for 2 to 4 hours under condensing and reflux, then cool down to room temperature under nitrogen protection, and let stand for 12 hours use.

[0134] The preparation method of the reactive film-forming resin (F) of the silane-terminated polyester hot-melt adhesive (containing 50% ethyl acetate solvent) with the structure of formula (5)...

Embodiment 3

[0140]

[0141] Concrete selection and mass percent of each component in table 3 embodiment 3

[0142] In this embodiment 3, the silane-modified polymer (A) is the silane-modified polyisoprene of formula I(b), and the preparation method is:

[0143] Use hydroxyl-terminated isoprene (mainly 1,2 addition structure, molecular weight 30,000,) use hydroxyl-terminated polybutadiene (POLY R-15, commercially available from CRAY VALLEY in the United States, obtained by free radical polymerization, with a number average molecular weight of 2500 to 2800 mol / g, and an average hydroxyl group functionality of 2.2 to 2.6) was mixed at a mass ratio of 1:1 and heated to 110°C And vacuum stirring and dehydration for 2h, and cooling to room temperature, the mixture of the obtained hydroxyl-terminated polybutadiene and hydroxyl-terminated polyisoprene is used as a raw material, firstly mixed with TDI (toluene diisocyanate, commercially available Commercially available) was reacted for 3 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com