Optical fiber bundle and manufacturing method thereof

A manufacturing method and technology of optical fiber bundles, applied in the direction of bundle optical fibers, etc., can solve the problems of limited number of optical fibers in optical fiber bundles, large adhesion area of optical fiber ribbons, difficult stripping, etc., and achieve stable processing quality, convenient stripping, and simple processing technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

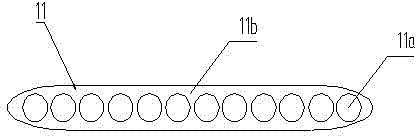

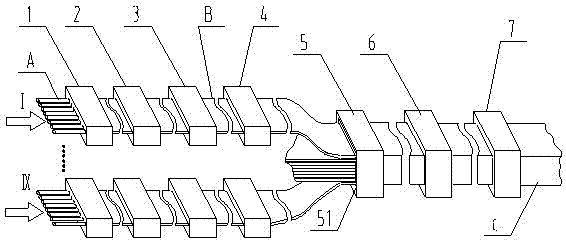

[0026] In this embodiment, an optical fiber with a diameter of 230-240 μm is used as a raw material, and a circular optical fiber bundle eye mask is used to produce a 64-core optical fiber bundle with a circular cross-section. For the production process, see Figure 5 ,details as follows:

[0027] Lay the above-mentioned eight optical fibers A up and down to form eight layers, and run forward at a speed of 145-155m / min through the optical fiber tape eye mask 1, UV resin at a pressure of 2.0-1.7bar and a flow rate of 70-90ml / min After entering the optical fiber belt eye mask 1, the optical fiber A is coated with UV resin and bonded to each other after entering the eye mask 1. Nitrogen cooling with a flow rate of 50 L / min forms eight optical fiber ribbons B. The eight optical fiber ribbons B respectively pass through the isolation layer coating liquid tank 4 of the corresponding layer at the above-mentioned speed. Silicon oil is built in the tank, and the outer surface of the o...

Embodiment 2

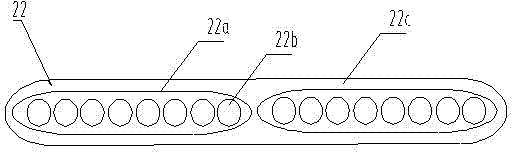

[0030] In this embodiment, an optical fiber ribbon containing eight cores (the diameter of the optical fiber in the optical fiber ribbon is 230-240 μm) is used as a raw material, and a square eye mask is used to produce a 64-core optical fiber bundle with a rectangular cross-section. The production process is shown in Image 6 ,details as follows:

[0031] The above eight optical fiber ribbons B are stacked and placed side by side, and pass through the isolation layer coating solution tank 4 of the corresponding layer at a speed of 145-155m / min. The isolation layer covered with silicone oil, the thickness of the isolation layer is about 0.01mm, the optical fiber ribbon quickly enters the optical fiber bundle eye mask 5, and the UV resin 3 enters the square optical fiber bundle eye mask 5 at a pressure flow of 2.0~1.7bar, eight optical fiber ribbons B enters the rectangular optical fiber bundle eye mask 5 and passes through the optical fiber bundle eye mask hole 51 and is coate...

Embodiment 3

[0034] In this embodiment, two 8-core optical fiber ribbons (the diameter of the optical fiber in the optical fiber ribbon is 230~240 μm) are used as raw materials to produce a 16-core optical fiber bundle with a rectangular cross-section. For the production process, see Image 6 ,details as follows:

[0035] The two optical fiber ribbons B pass through the isolation layer coating liquid tank 4 of the corresponding layer at a speed of 145-155m / min. Silicon oil is built in the tank. The thickness is about 0.01mm. This optical fiber ribbon enters the optical fiber bundle eye mask 5 very quickly, the UV resin 3 enters the optical fiber bundle eye mask 5 with a pressure of 2.0-1.7 bar, and the two optical fiber ribbons B enter the optical fiber bundle eye mask 5 and pass through the rectangular optical fiber bundle eye mask 51 After being coated with UV resin and bonded to each other, when irradiated by a UV lamp with an illumination of 4500-6000W in the UV light box 6, the silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com