Patents

Literature

55results about How to "Large number of cores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

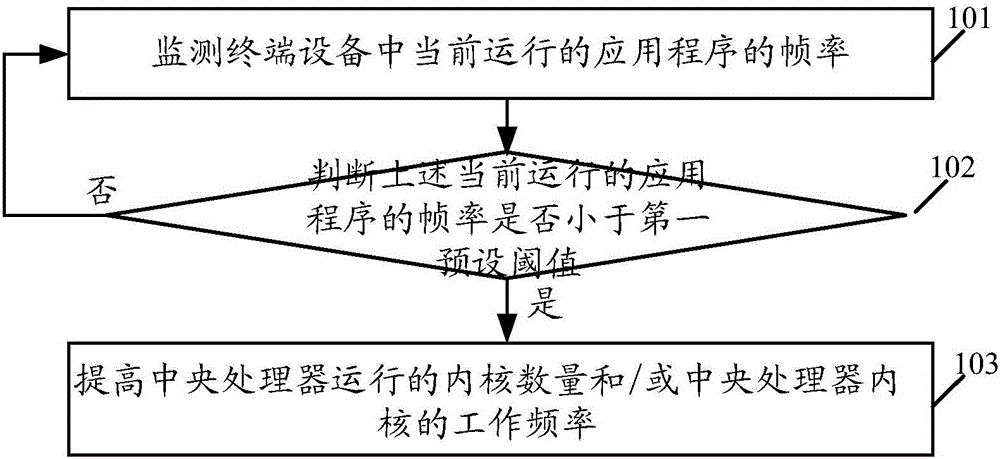

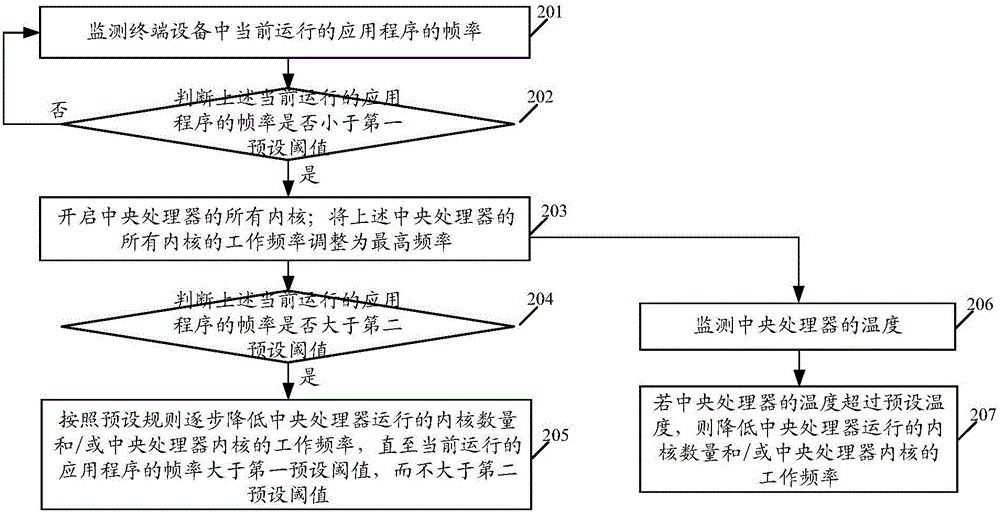

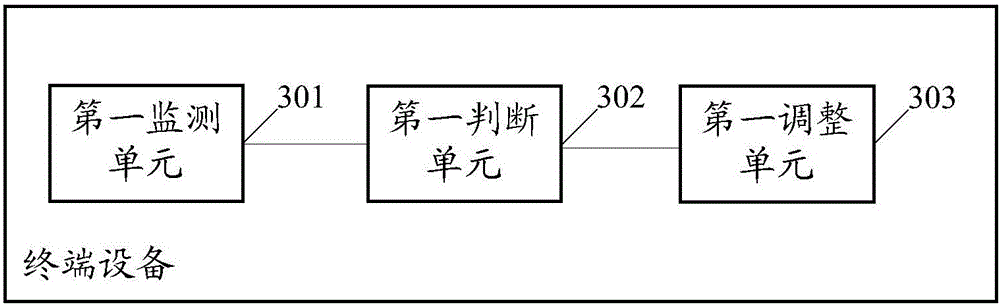

Control method for central processing unit and terminal equipment

ActiveCN106020990AIncrease the number of coresIncrease working frequencyResource allocationEnergy efficient computingTerminal equipmentCPU power dissipation

The embodiment of the invention discloses a control method for a central processing unit and terminal equipment, which are applied to the technical field of mobile communications. The method in the embodiment of the invention comprises the following steps of monitoring the frame rate of a currently-running application program in the terminal equipment; judging whether the frame rate of the currently-running application program is smaller than a first preset threshold or not; if the frame rate of the currently-running application program is smaller than the first preset threshold, improving the number of running kernels of the central processing unit and / or the working frequency of the kernels of the central processing unit. According to the embodiment of the invention, the power consumption of a CPU (Central Processing Unit) and the limitation of performance optimization are reduced.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

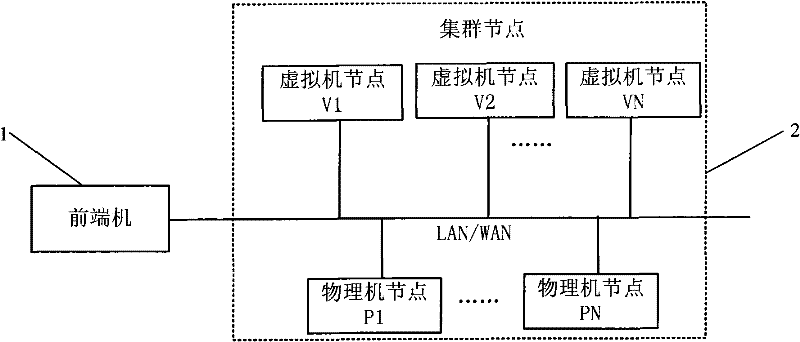

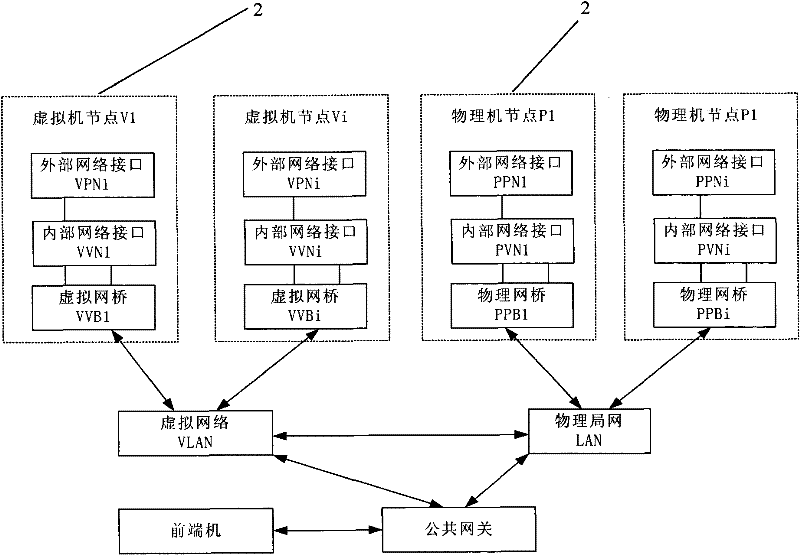

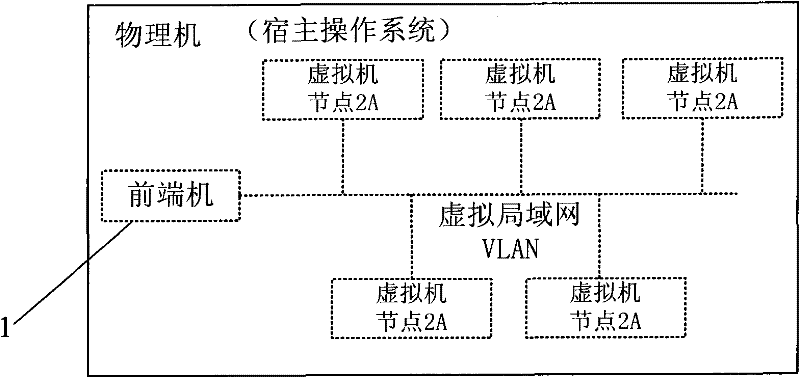

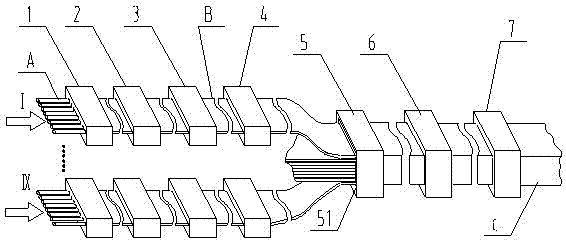

A virtual computer cluster and its implementation method

InactiveCN102271145ALow costImprove efficiencyNetworks interconnectionVirtualizationComputer cluster

The invention relates to the technical field of computing system virtualization, in particular to a virtual computer cluster and an implementation method thereof. Including a front-end machine and several cluster nodes, the front-end machine is a virtual machine or a physical machine; the cluster node is a virtual machine node or a physical machine node; the front-end machine is connected to the cluster node and the cluster node through a physical or virtual network card . During the cluster implementation process, the cluster management software is installed on the front-end computer, and the node monitoring program is installed on each node to construct a software system of virtual computer cluster. The cluster and its implementation method of the present invention provide a single virtual resource expansion method to support occasions where users have special requirements for computing resources, storage resources, security and stability of computing systems. It can be widely used in computer virtualization technology.

Owner:G CLOUD TECH

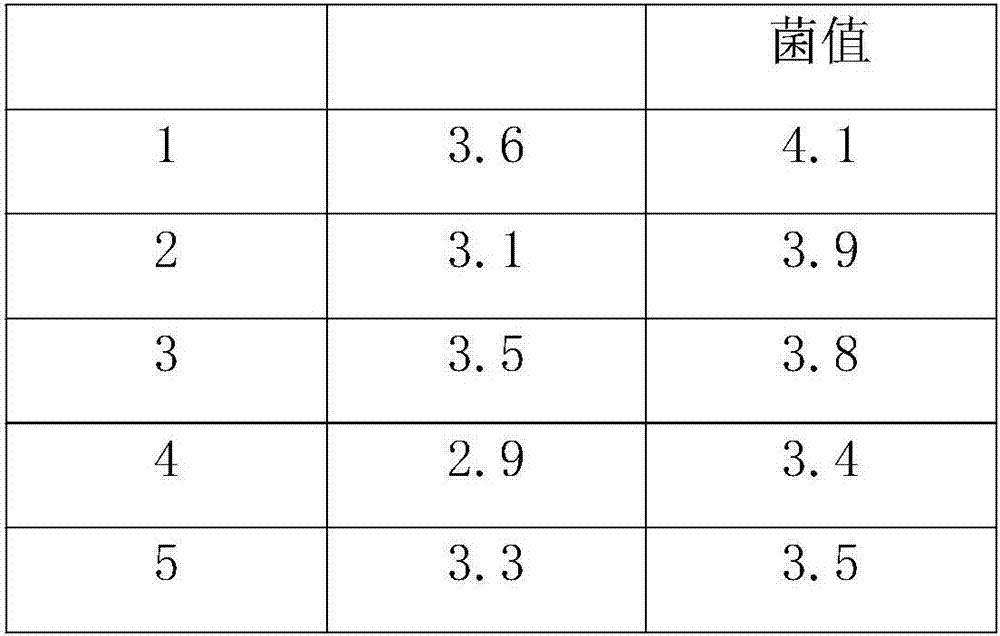

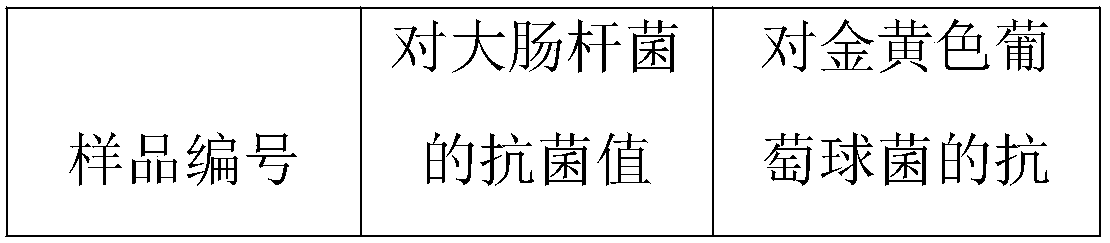

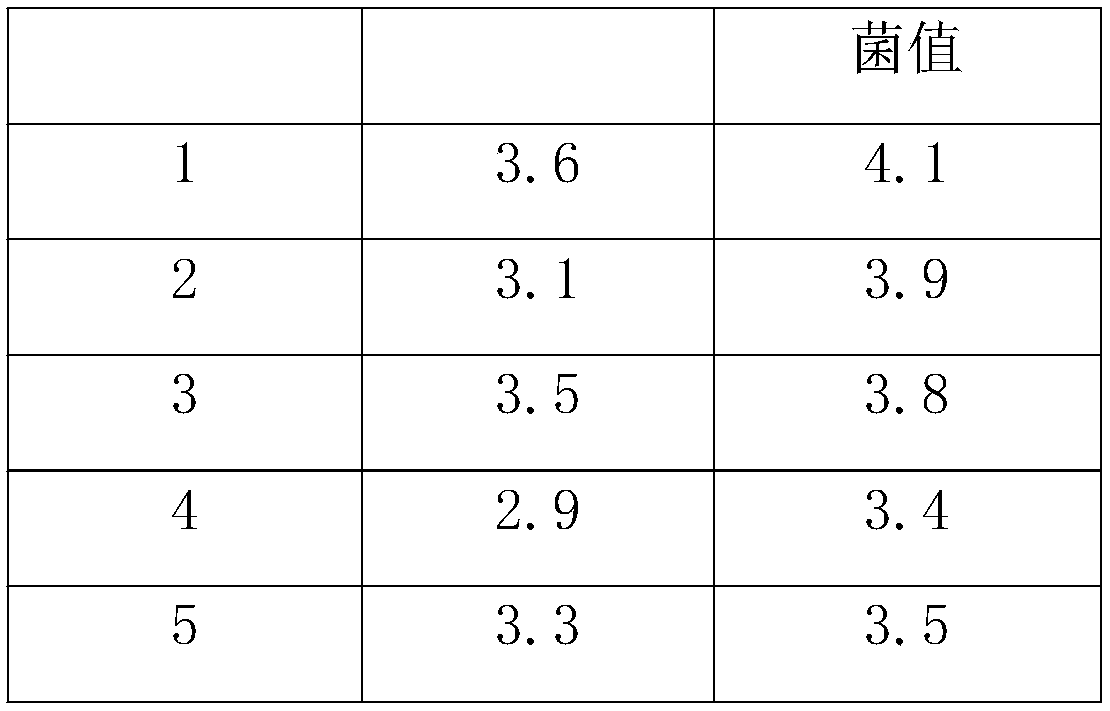

High-strength antibacterial aluminum alloy for aluminum alloy ladder and preparation method thereof

ActiveCN107201469AHigh hardnessImprove toughnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to the technical field of aluminum alloy ladder preparation, and particularly relates to high-strength antibacterial aluminum alloy for an aluminum alloy ladder and a preparation method thereof. The aluminum alloy comprises a high-strength aluminum alloy matrix and a micro-arc oxidation film, wherein the micro-arc oxidation film is arranged on the surface of the aluminum alloy matrix, the weight of a hole sealing agent on the micro-arc oxidation film is 0.15 g / cm<2> to 0.90 g / cm<2>, and the hole sealing agent covers at least 92% of micropores in the micro-arc oxidation film. The preparation method comprises the steps of smelting metal, modifying, refining and degassing, pouring and forming and performing quenching treatment, aging treatment, micro-arc oxidation and hole sealing treatment, wherein in the step of modifying, nanometer modificators are uniformly dispersed into liquid alloy obtained by smelting; in the step of refining and degassing, 0.23% to 0.38% of hexachloroethane is added to the modified liquid alloy so as to refine and degas; and the aging treatment is divided into four-stage aging treatment. The aluminum alloy prepared by adopting the preparation method has the characteristics of high hardness, high strength, wear resistance, corrosion resistance, good anti-cracking performance, good antibacterial effect, difficulty in aging and deformation and long service life.

Owner:浙江洋铭实业有限公司

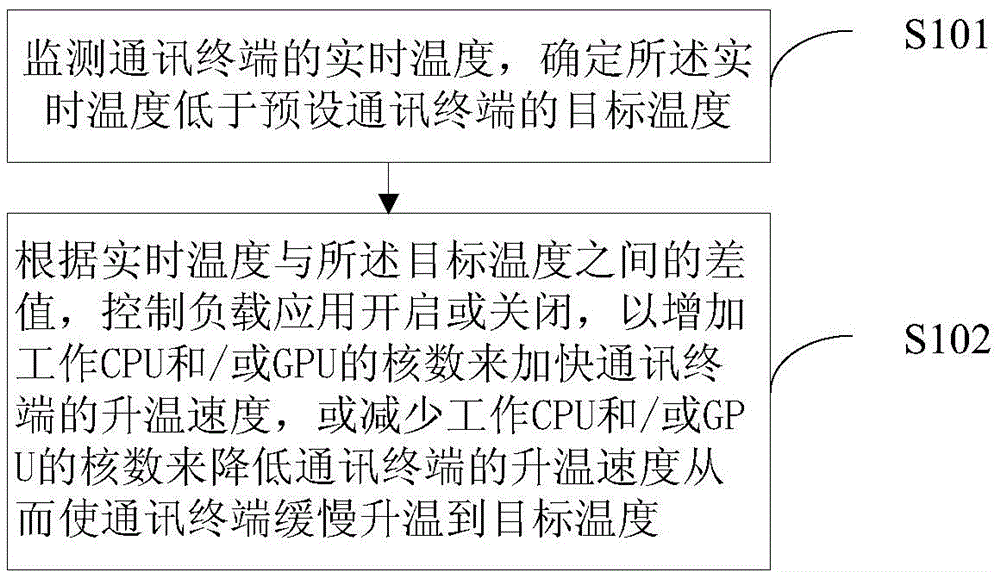

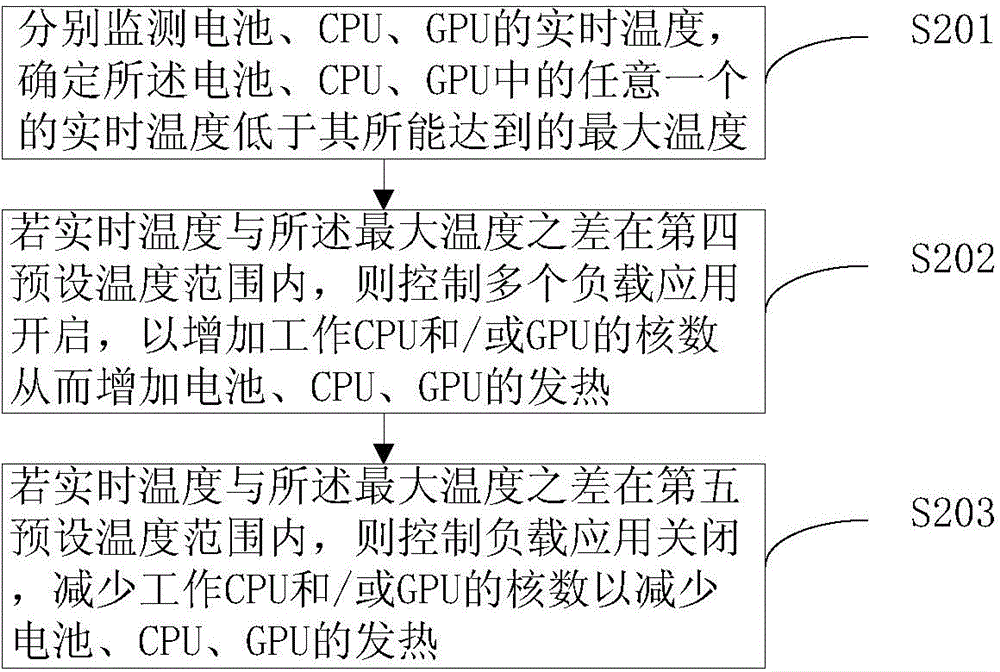

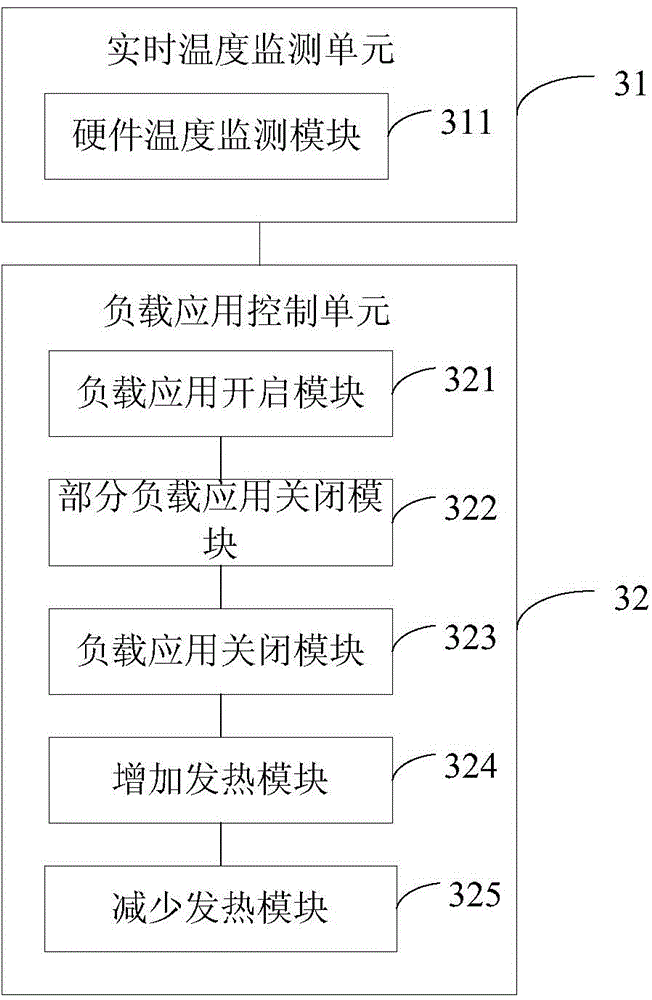

Communication terminal temperature control method and device

ActiveCN104536483AFast heatingReduce heating rateTemperature control using electric meansTemperature controlComputer terminal

The invention relates to the technical field of communication, in particular to a communication terminal temperature control method and device. According to the method and device, the real-time temperature of a communication terminal is monitored, it is determined that the real-time temperature is lower than the target temperature of the preset communication terminal; a load application is controlled to be opened or closed according to the difference value between the real-time temperature and the target temperature, the temperature rising speed of the communication terminal is increased by increasing the core number of a working CPU and / or a working GPU, or the temperature rising speed of the communication terminal is reduced by reducing the core number of the working CPU and / or working GPU so as to enable the temperature of the communication terminal to rise to the target temperature slowly. The load application is controlled to be opened or closed by monitoring the difference value between the real-time temperature and the target temperature of the communication terminal so as to increase or reduce the temperature rising speed of the communication terminal, high-temperature and constant-temperature control of the communication terminal is achieved through utilization of waste gas heat, and the heating bag function is achieved.

Owner:SHANGHAI ZHUO YOU NETWORK TECH

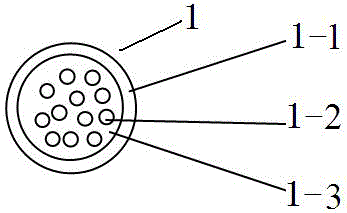

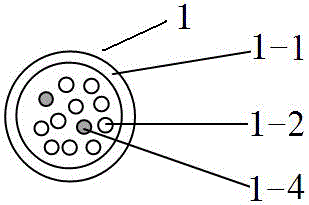

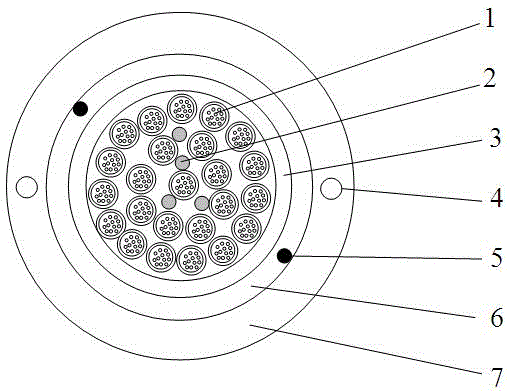

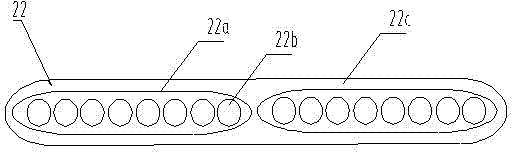

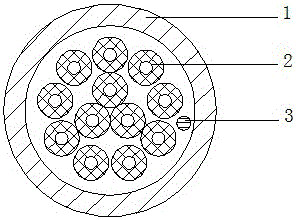

All-dielectric large-core-number high-density micro pipeline wiring cable and manufacturing method thereof

The invention relates to an all-dielectric large-core-number high-density micro pipeline wiring cable and a manufacturing method of the all-dielectric large-core-number high-density micro pipeline wiring cable and belongs to the technical field of optical communication cable manufacturing. The all-dielectric large-core-number high-density micro pipeline wiring cable is a data communication optical cable and is suitable for various laying conditions of outdoor pipelines, overheads, road surfaces and the like and can be used for environments of long-distance communication, interoffice communication, indoor introduction and the like. The all-dielectric large-core-number high-density micro pipeline wiring cable has the advantages of being large in core number, small in outer diameter, high in tensile strength, high in side-pressure-resisting capability, good in water blocking effect and bending capability, easy to construct, easy to bifurcate and the like. The all-dielectric large-core-number high-density micro pipeline wiring cable is composed of a water blocking type optical fiber micro pipe, large line density water blocking yarn, a water blocking band, glassfiber reinforced plastic rods, aramid fibers, a tearing rope and an outer protection sleeve. The water blocking type optical fiber micro pipe is twisted to form a water blocking type optical fiber micro pipe cable core, the outer portion of the water stopping type optical fiber micro pipe cable core is longitudinally wrapped through the double-face insulating type water blocking band, the high-strength aramid fibers and the tearing rope serve as strengthening parts, the two glassfiber reinforced plastic rods are adopted in the outer layer to be strengthened in the outer protection sleeve in parallel, and the tensile performance of the all-dielectric large-core-number high-density micro pipeline wiring cable is enhanced.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

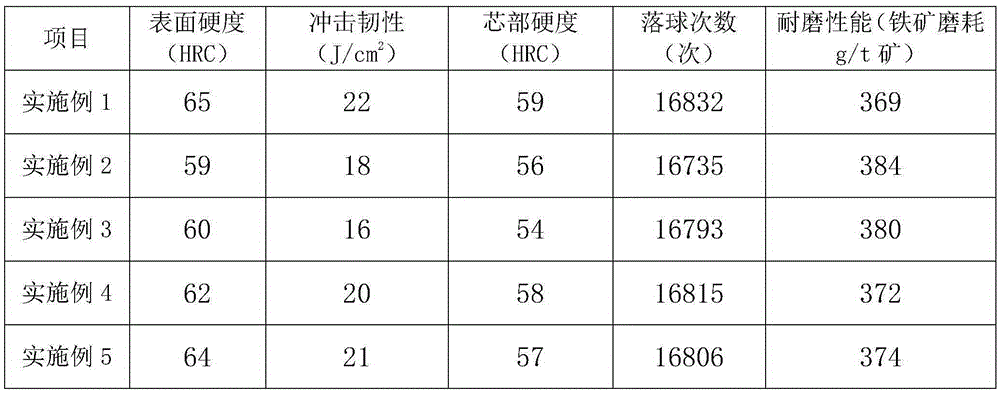

Preparation method of high-manganese low-chromium alloy wear-resisting ball

The invention provides a preparation method of a high-manganese low-chromium alloy wear-resisting ball. The preparation method comprises the steps that raw materials are firstly smelted to obtain alloy liquid, and modification is carried out on the alloy liquid; a covering agent is added to the surface of the alloy liquid obtained after modification, still standing is carried out, refining desulfuration and deoxygenation are carried out, and detection is carried out; the alloy liquid is poured, and a casting is obtained through casting forming and cleaning; and the casting is precooled, the precooled casting is placed in a NaNO2 saline solution for quenching treatment, tempering treatment is carried out after quenching is finished, and finally the finished high-carbon middle-chromium alloy wear-resisting ball is obtained after the casting is cooled to room temperature. According to the prepared high-manganese low-chromium alloy wear-resisting ball, tensile strength is improved by 0.7%, yield strength is improved by 6.1%, ductility is improved by 10.8%, impact toughness is improved by 17.9%, and hardness is improved by 0.3 of HRC.

Owner:NINGGUO SOUTHERN WEAR RESISTANT MATERIALS

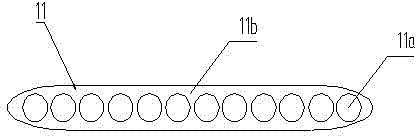

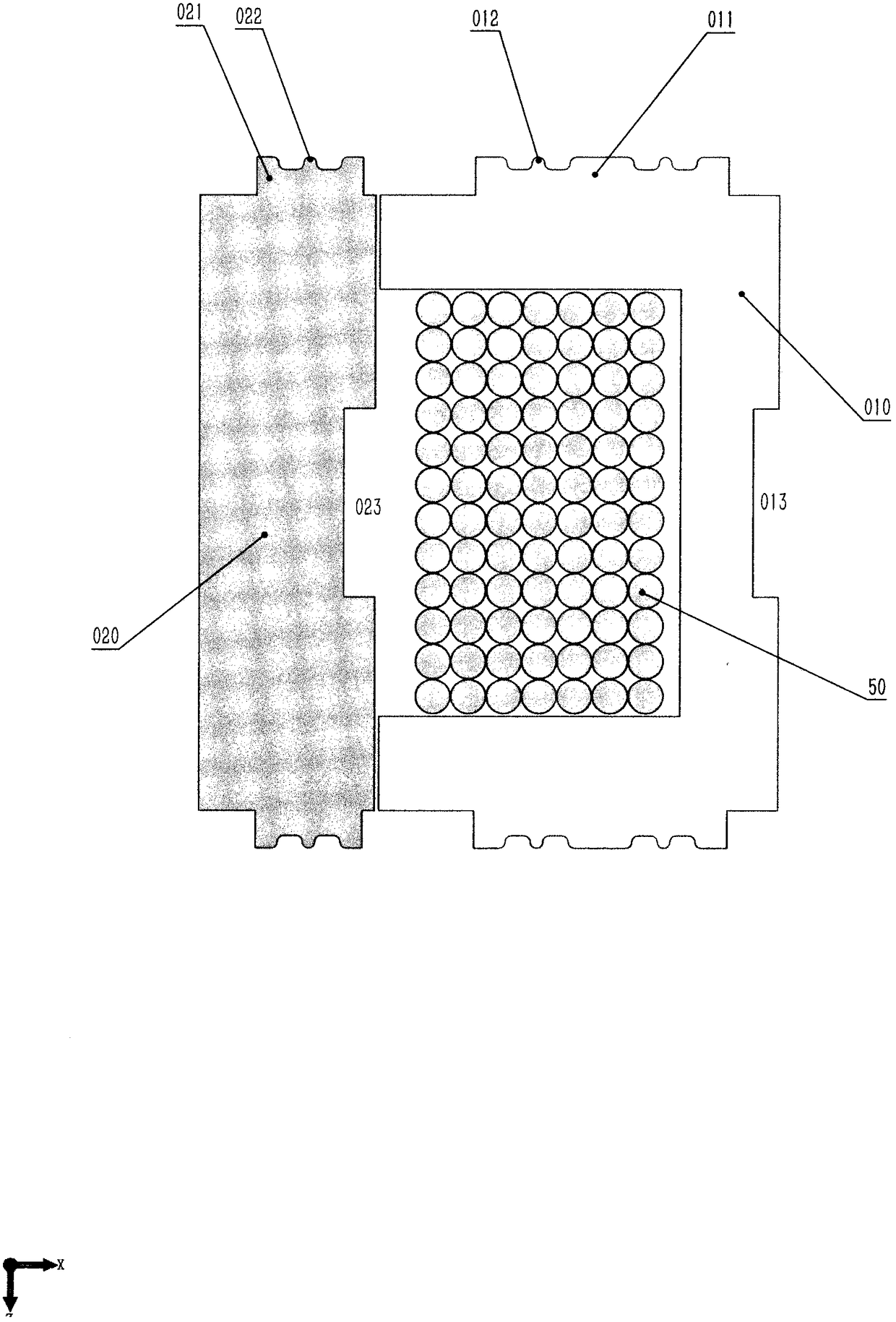

Optical fiber bundle and manufacturing method thereof

InactiveCN102393547ASolve bonding problemsFacilitate strippingBundled fibre light guideIsolation layerEngineering

The invention relates to the technical filed of optical fiber, and particularly relates to an optical fiber bundle and a manufacturing method thereof. The UV (Ultraviolet) optical fiber bundle comprises a plurality of optical fiber ribbons, each optical fiber ribbon is provided with an isolation layer on the outer surface along the ribbon length, the plurality of optical fiber ribbons with isolation layers are stacked and consolidated by UV (Ultraviolet) resin integrally. 2 to 12 optical fiber ribbons are stacked into 2 to 12 layers. The optical fiber ribbons are wrapped. A plurality of stacked optical fiber ribbons are consolidated as optical fiber bundles with circular or rectangular cross sections by UV resin; the diameter of the optical fiber bundle with a circular cross section is 3000 to 3050mu m, the long side of the optical fiber bundle with a rectangular cross section is 2150 to 2200mu m long. The optical fiber bundle contains 2 to 8 optical fiber ribbons which are stacked in parallel, and each optical fiber ribbon contains 8 optical fibers tiled horizontally and in parallel. The optical fiber bundle is manufactured by stacking and placing the optical fiber ribbons in parallel, thus overcoming the technical prejudice in prior art that the optical fiber ribbons in the optical fiber bundle cannot be stacked and placed in parallel and meeting the requirement of people on optical cables with a large number of cores, the processing technology is simple and the processing quality is stable.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

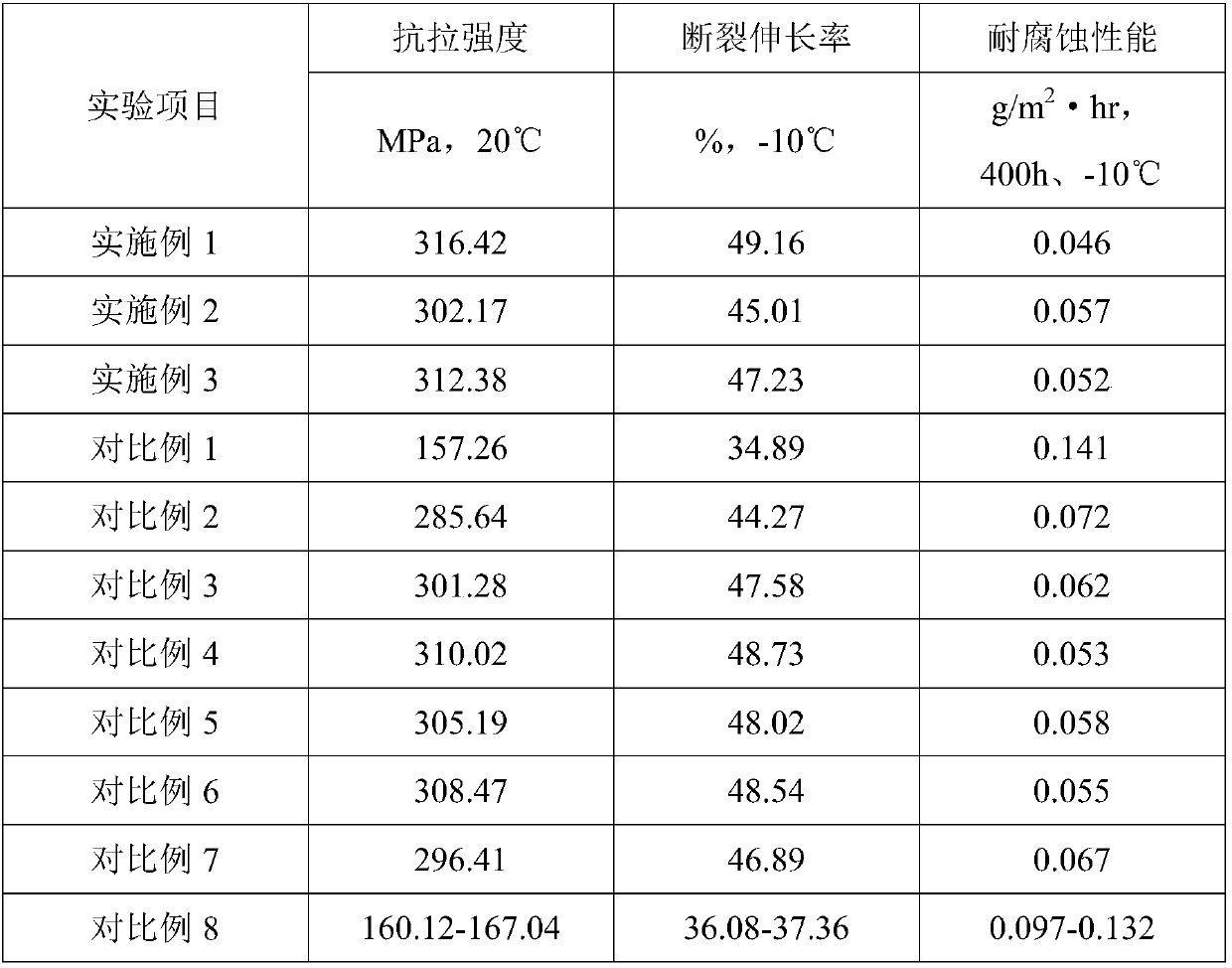

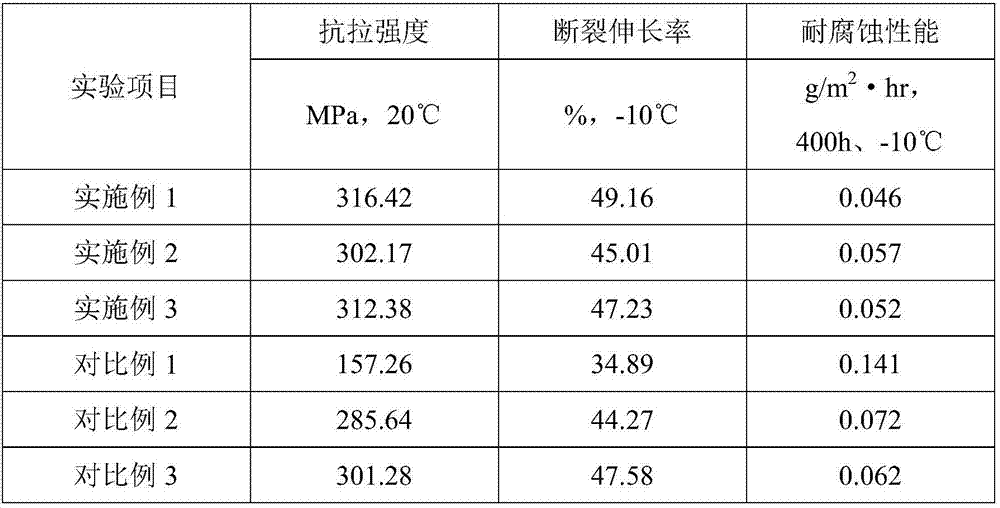

Preparing method for rare earth aluminum alloy material good in corrosion-resisting performance

The invention discloses a preparing method for a rare earth aluminum alloy material good in corrosion-resisting performance and belongs to the technical field of preparing of aluminum alloys. The rareearth aluminum alloy material comprises the following raw materials including aluminum, copper, vanadium, manganese, tin, chromium, rare earth elements, titanium carbide, tungsten carbide, tungsten silicide, tungsten, a refeining agent and a grain refining agent. The rare earth aluminum alloy material is prepared through the steps of melting, refining, drossing, casting and the like. By the adoption of the technology, the corrosion-resisting performance of the rare earth aluminum alloy material can be obviously improved.

Owner:广西丰达三维科技有限公司

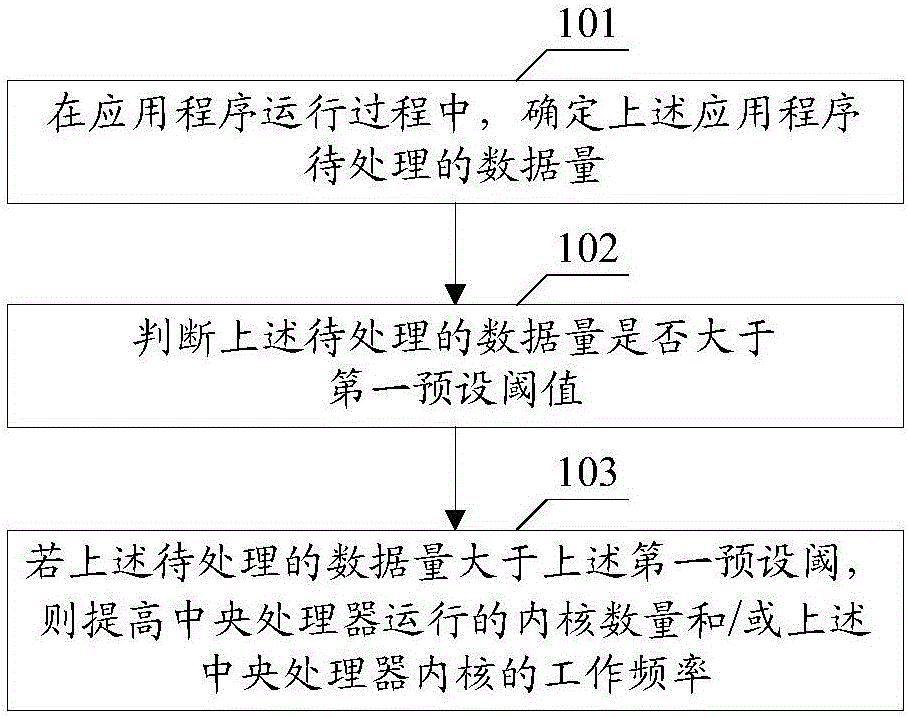

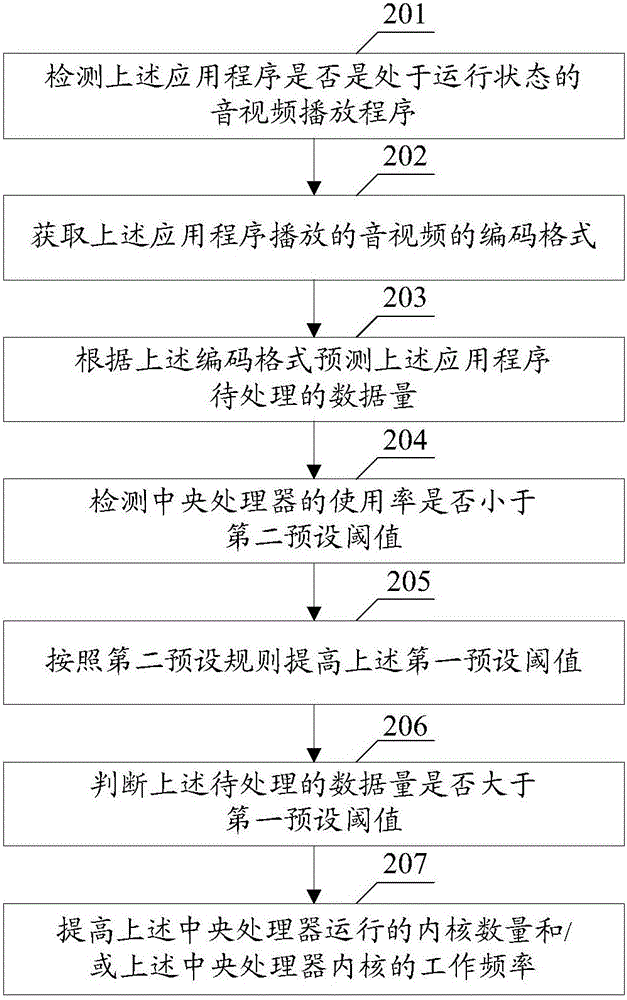

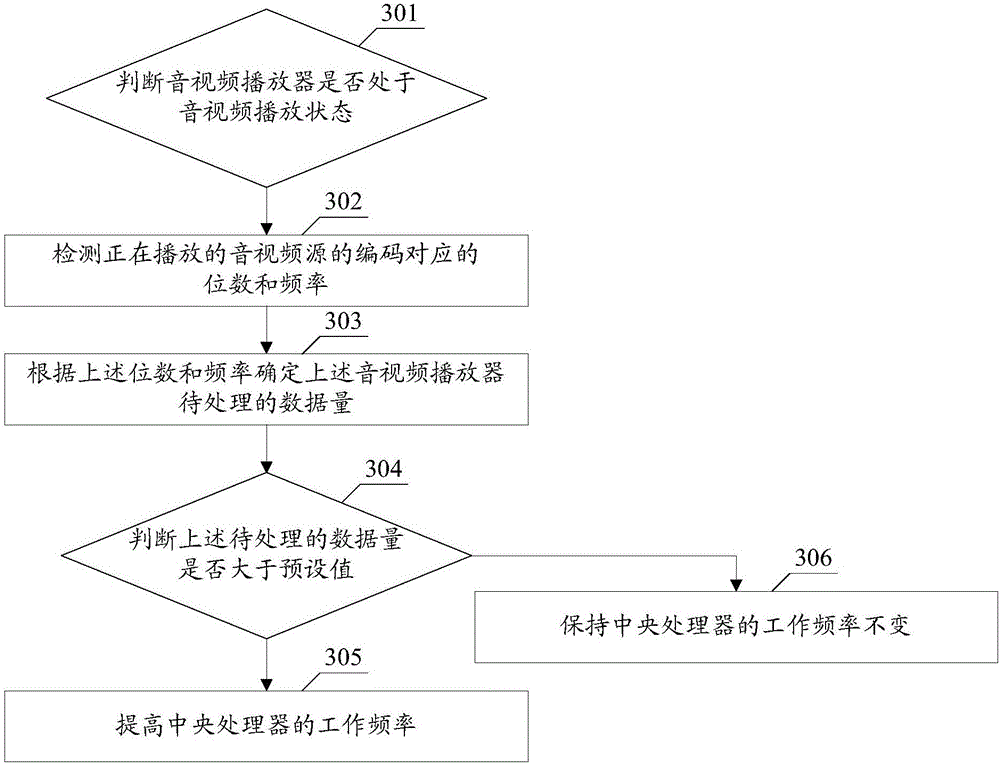

Control method of central processing unit and terminal equipment

InactiveCN106527666AImprove fluencyIncrease the number of coresResource allocationPower supply for data processingElectricityOperating frequency

The embodiment of the invention discloses a control method of a central processing unit and terminal equipment. The method comprises the steps that the to-be-processed data volume of an application program is determined in the running process of the application program; whether the to-be-processed data volume is larger than a first preset threshold value or not is judged; if yes, the number and / or the working frequency of running cores of the central processing unit is increased. When the to-be-processed data volume of the application program of the terminal equipment is larger than the first preset threshold value, the number and / or the working frequency of the cores of the central processing unit is increased; when the to-be-processed data volume of the application program of the terminal equipment is smaller than the first preset threshold value, the working frequency of the central processing unit keeps invariable. According to the scheme, electricity consumption can be reduced, and the running smoothness of the application program can be improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

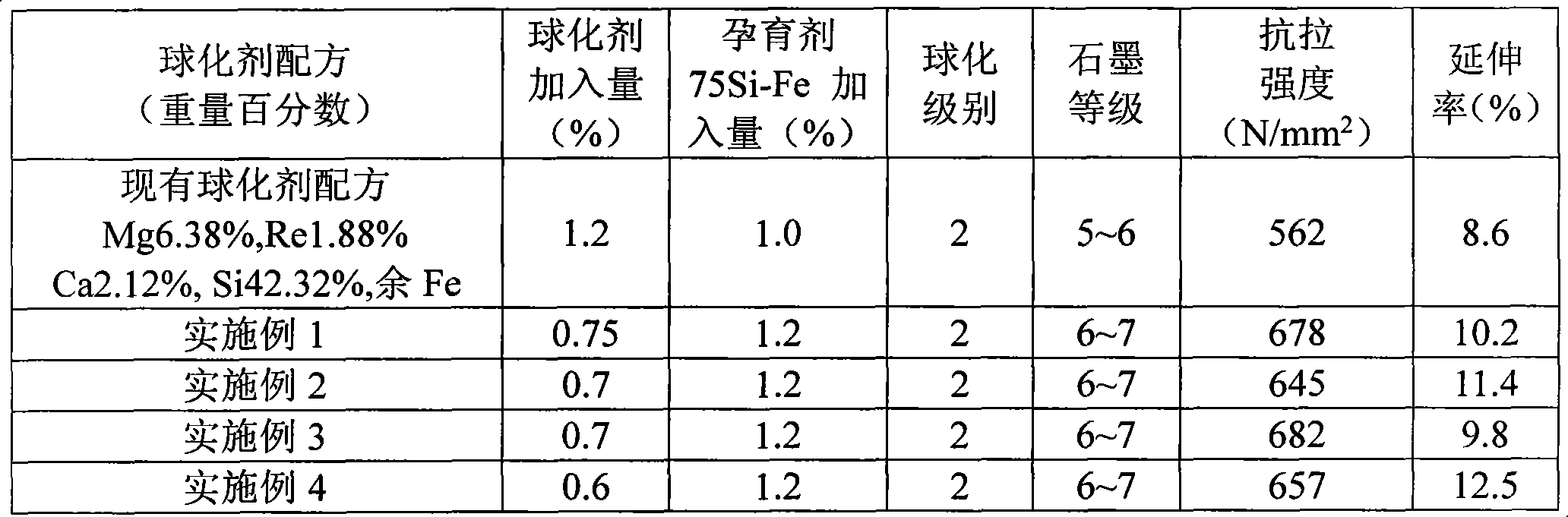

Nodular cast iron rare-earth magnesium silicon nodularizer

The invention relates to a nodular cast iron rare-earth magnesium silicon nodularizer, comprising the following components by weight percent: 12-15% of Mg, 0.5-2.0% of Re, 42-50% of Si, 3.5-5.5% of Ca, 0.5-1.0% of Ba, 2.0-5.0% of Mn, 0.5-1.5% of C, less than 1.5% of Al, and the balance of Fe. The components are prepared into granules by a conventional mix-melting method and crushing, so as to obtain the nodular cast iron rare-earth magnesium silicon nodularizer. The nodularizer is in an irregular block shape; the grain size is 3-25mm or 5-40mm. According to the nodular cast iron rare-earth magnesium silicon nodularizer, the content of magnesium is improved; the spheroidisation cost can be significantly reduced; meanwhile, the nodular cast iron rare-earth magnesium silicon nodularizer is stable in spheroidisation quality and good in graphite ball roundness; the effects such as purification of molten iron, facilitation of graphitization, delaying of degraded spheroidization and facilitation of nucleation refined organization and the like can be achieved by adding Re, Ca, Ba, Mn and C.

Owner:WUXI NOVEL SPECIAL METAL

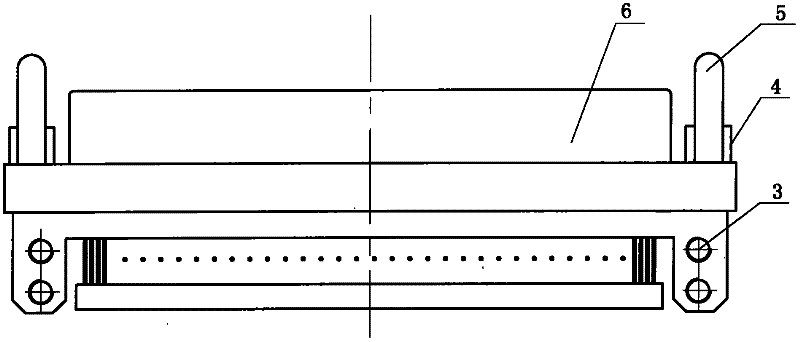

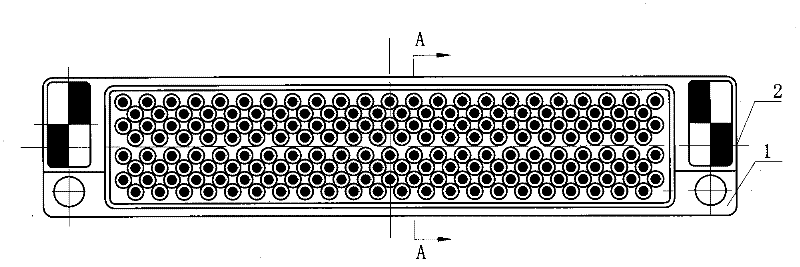

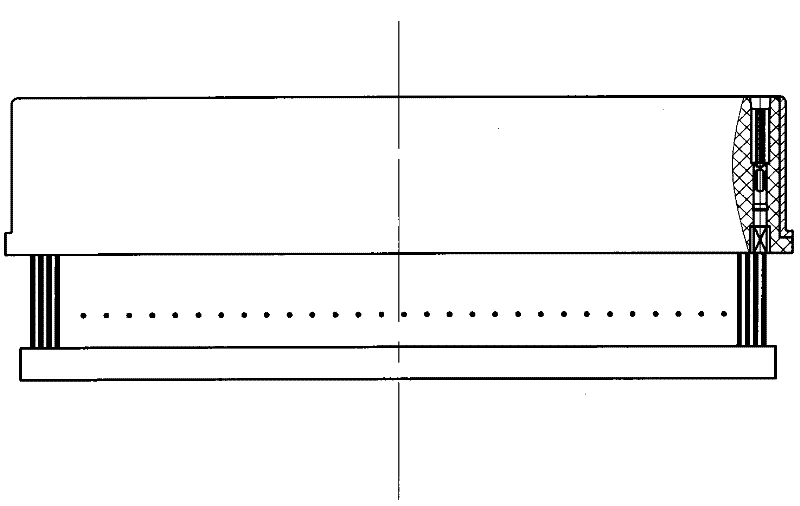

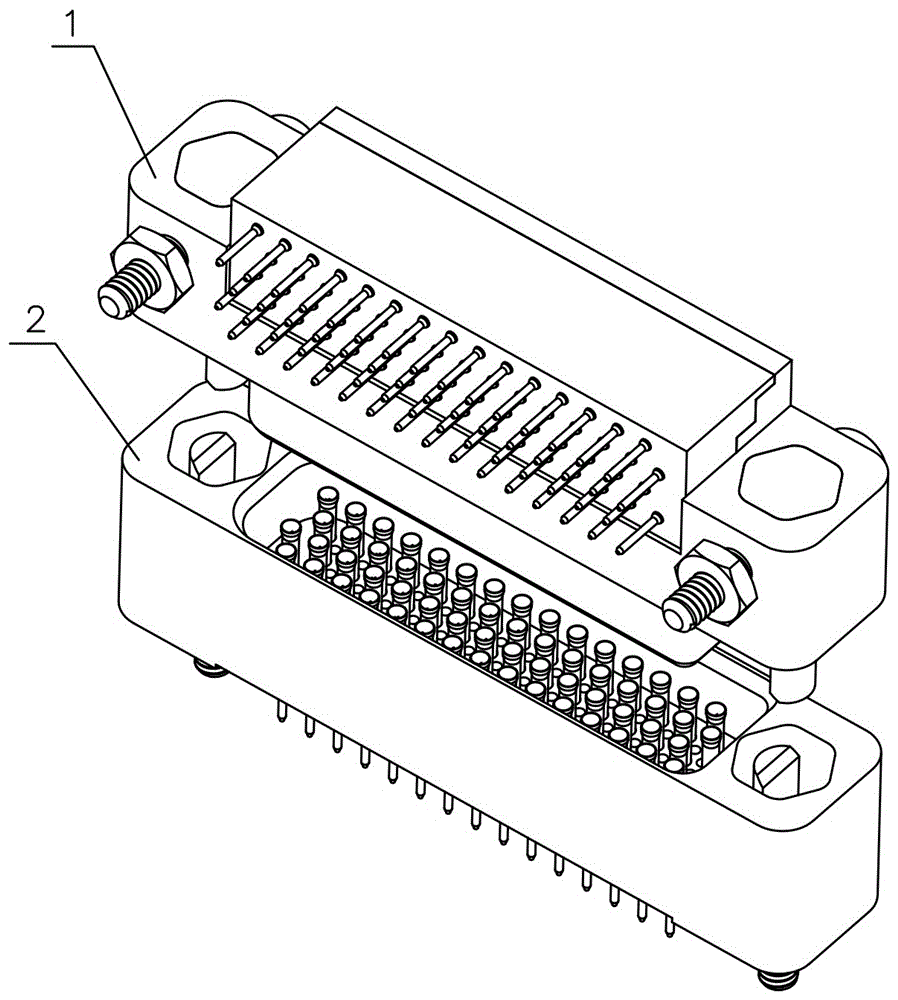

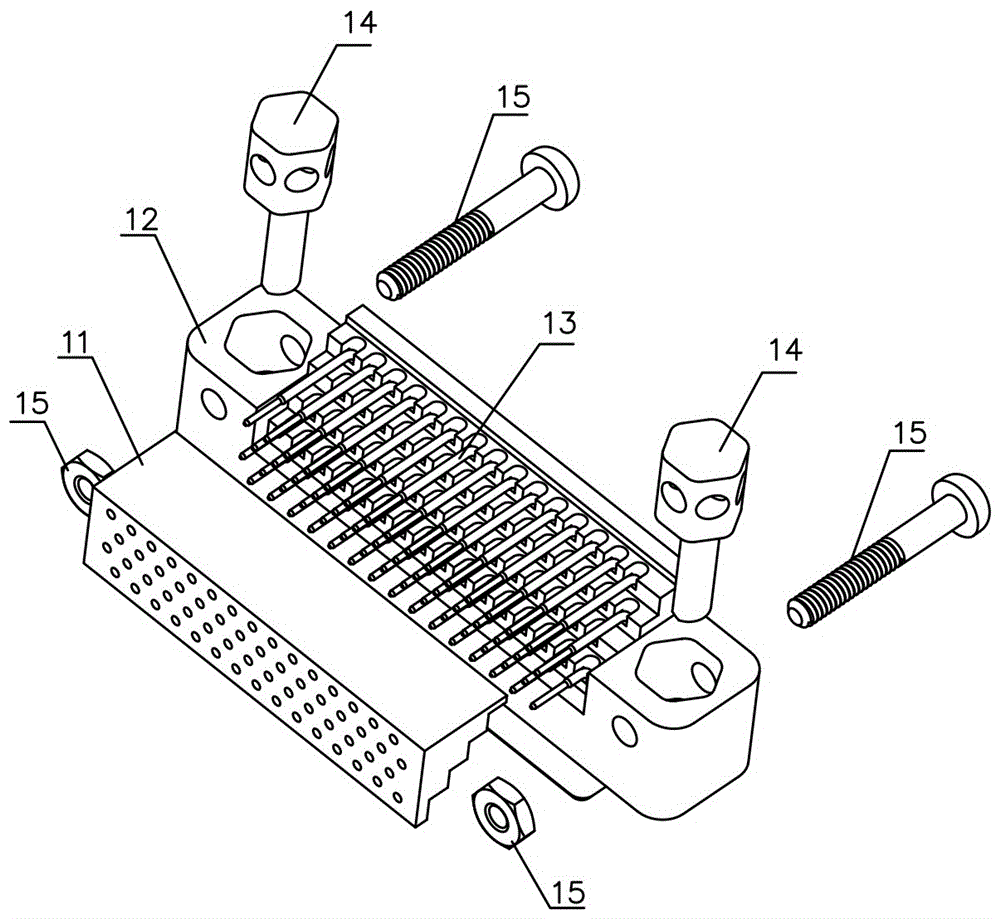

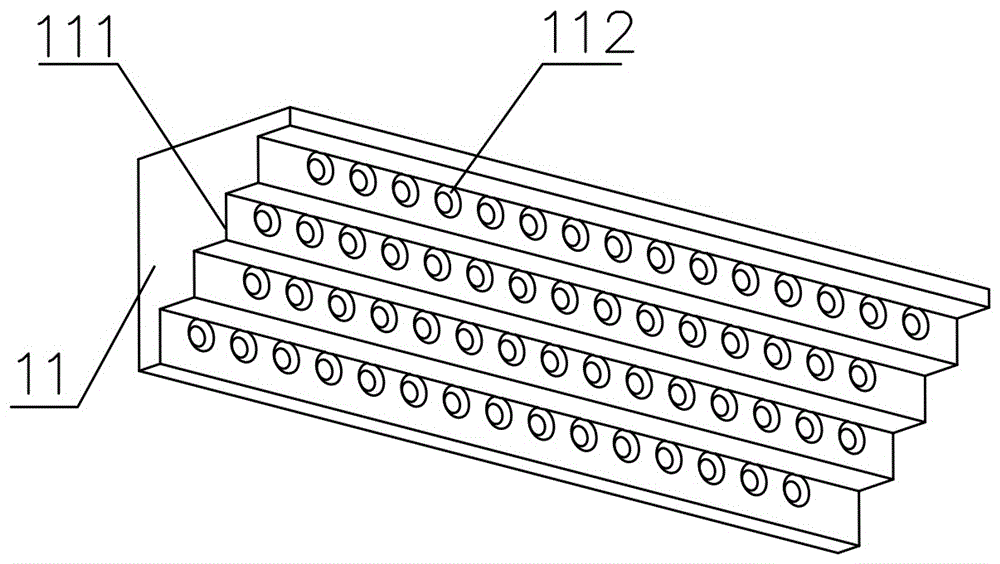

LRM (Line replaceable module) low-frequency high-density surface mount connector plug

InactiveCN102176558AIncrease the arrangement densityLarge number of coresIncorrect coupling preventionCoupling contact membersInterference fitHigh density

The invention provides an LRM (Line replaceable module) low-frequency high-density surface mount connector plug, which comprises a shell A, a shell B, a lock screw, a guide pin, a coding piece and a low-frequency high-density surface mount base assembly, wherein the flange of the low-frequency high-density base assembly is clamped by the grooves of the shell A and shell B; the shell A and the shell B are fixed together by screws so as to fix the connector; the guide pin is locked in a corresponding screwed holes on the shells in a thread way, and the coding piece is in the interference fit with the grooves of the shells. The connector plug has simple structure, spectrum arrangement density and core quantity can be increased by changing the end connection mode of ends. The invention provides a 2-row circular arc surface-mount structure for a connector, which is formed by bending the tail ends of 8 rows of contact elements.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

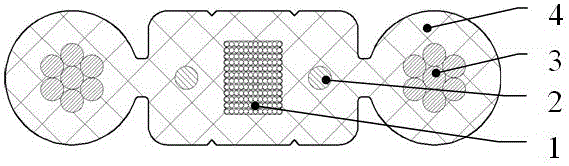

Dual self-holding optical fiber ribbon type wiring optical cable

InactiveCN105954845AImprove protectionPlay a tensile roleFibre mechanical structuresFiberEngineering

The invention discloses a dual self-holding optical fiber ribbon type wiring optical cable. The dual self-holding optical fiber ribbon type wiring optical cable comprises an optical fiber ribbon, reinforcement members, messenger wires and an oversheath. The wiring optical cable is symmetrical on the left and on the right; the optical fiber ribbon is disposed at the center of the wiring optical cable; the two messenger wires are respectively disposed at the left end and the right end of the wiring optical cable; the two reinforcement members are respectively disposed between the optical fiber ribbon and the corresponding messenger wires; and the oversheath is disposed at the peripheral side of the wiring optical cable. The wiring optical cable provided by the invention is large in cable core number, small in dimension and high in tensile strength, and can be applied to machine room wiring or fiber to the premise of indoor and outdoor buildings.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

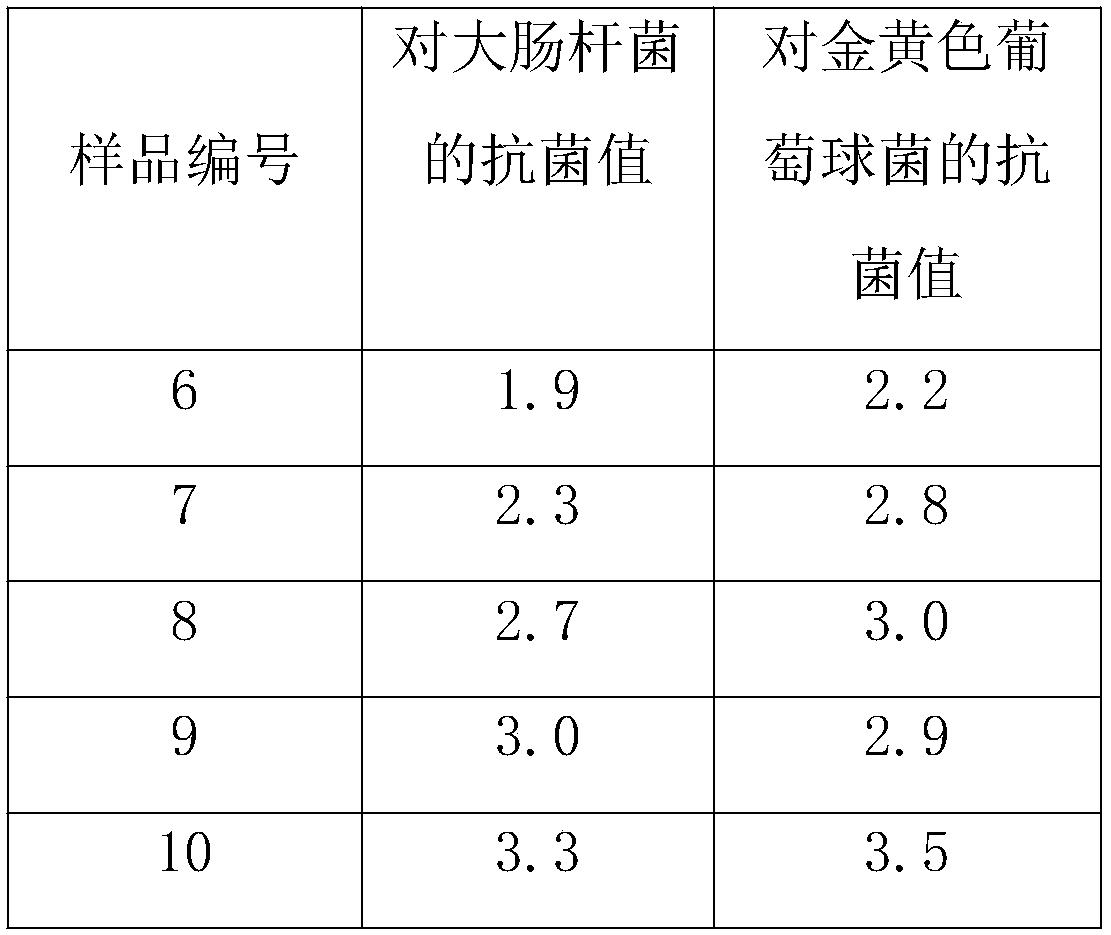

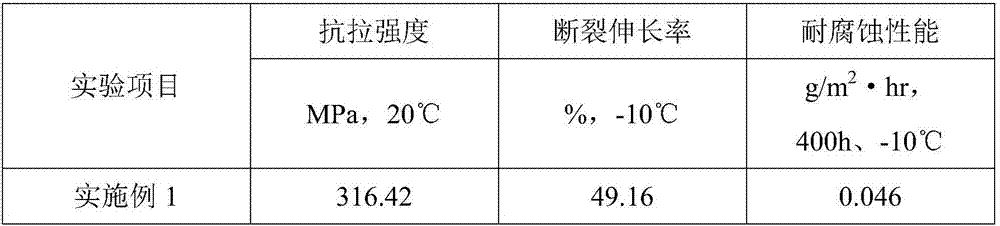

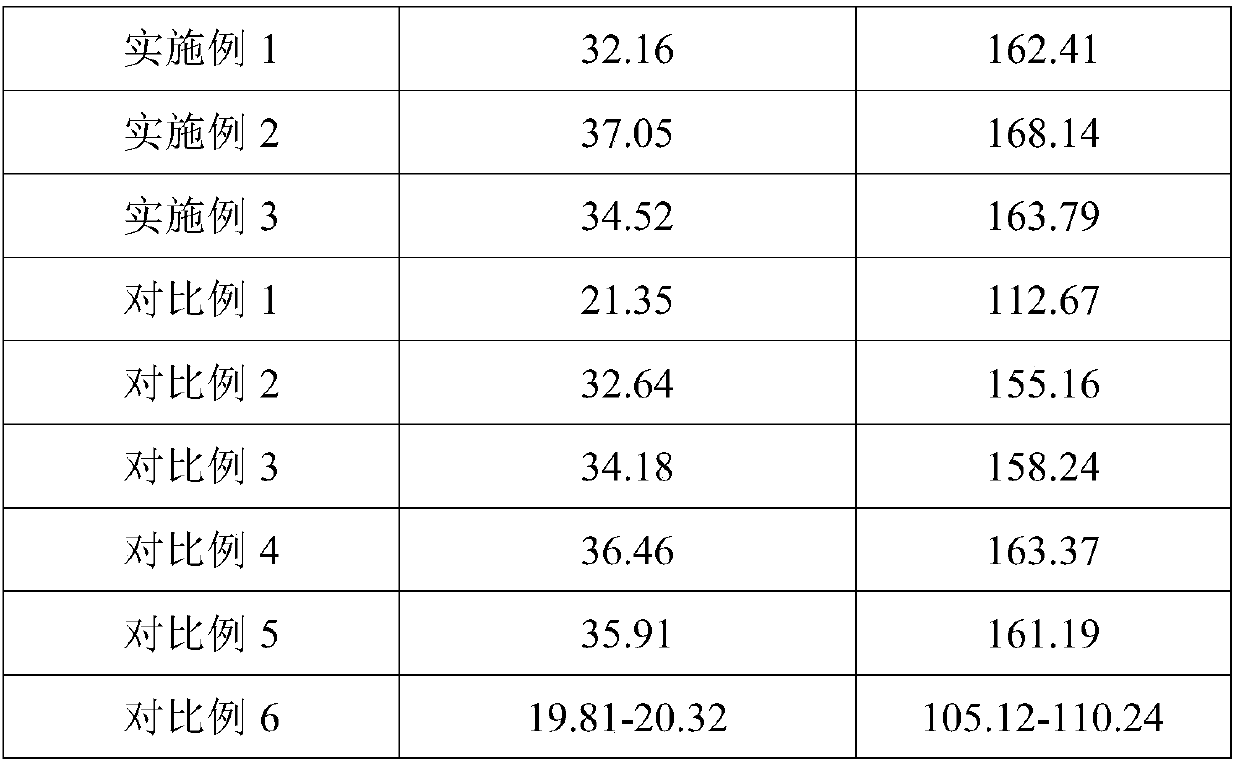

Rare earth aluminum alloy

The invention discloses a rare earth aluminum alloy, and belongs to the technical field of aluminum alloy preparing. The rare earth aluminum alloy comprises the following raw materials of aluminum, copper, vanadium, manganese, tin, chromium, a rare earth element, titanium carbide, tungsten carbide, tungsten silicide, tungsten, a refining agent and a grain refiner; and the rare earth aluminum alloyis prepared through the steps of fusion, refining, drossing, casting and the like. By means of the process, the strength of extension, the elongation at break and the corrosion resistance of the rareearth aluminum alloy can be obviously improved.

Owner:广西丰达三维科技有限公司

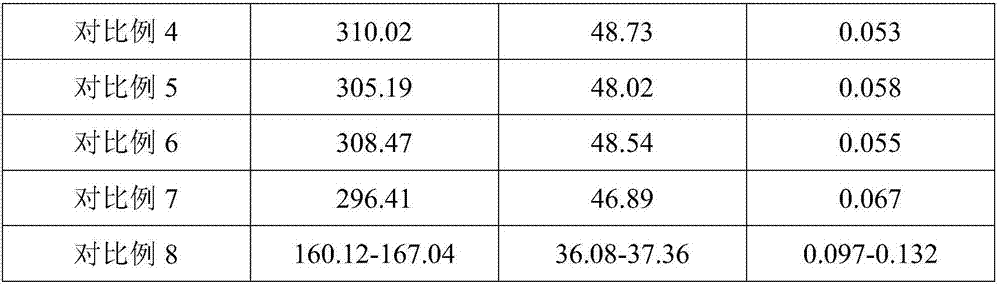

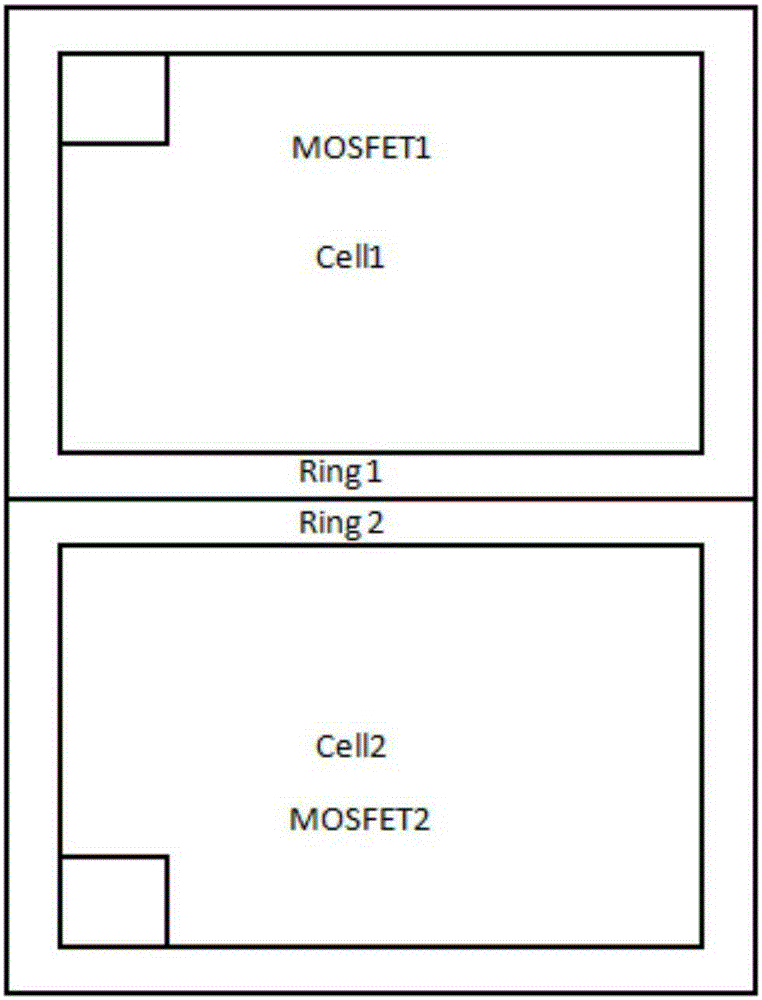

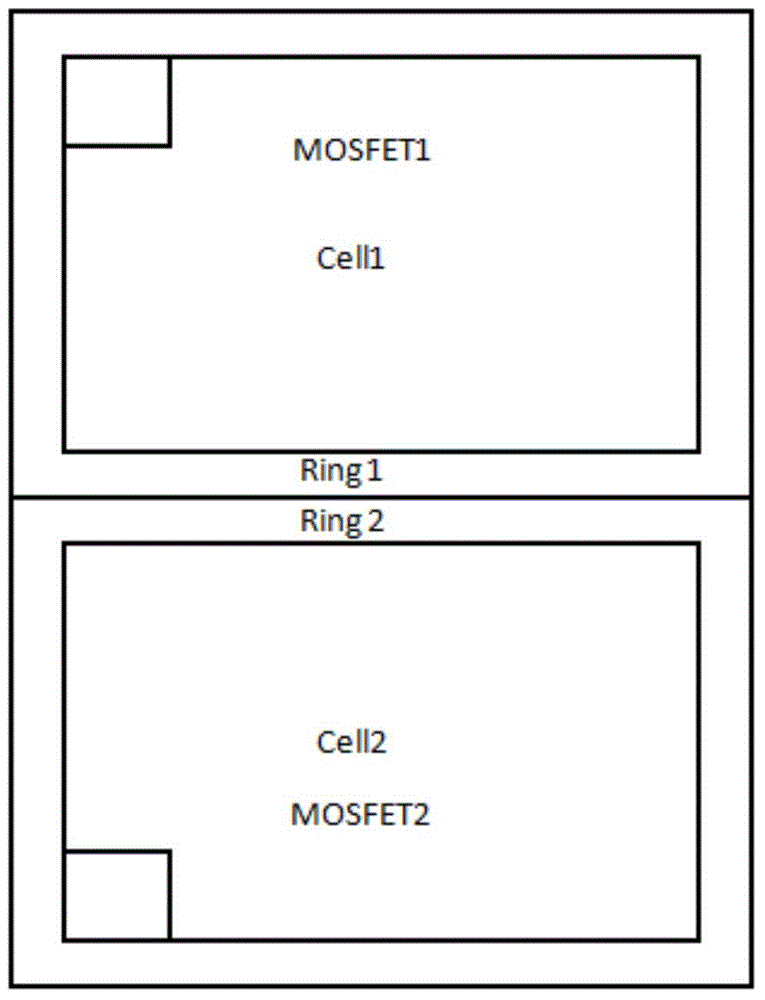

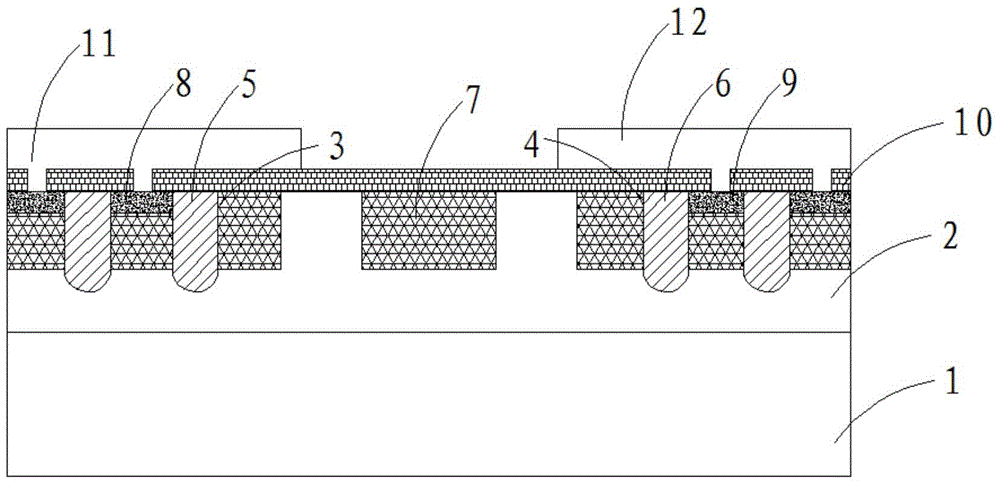

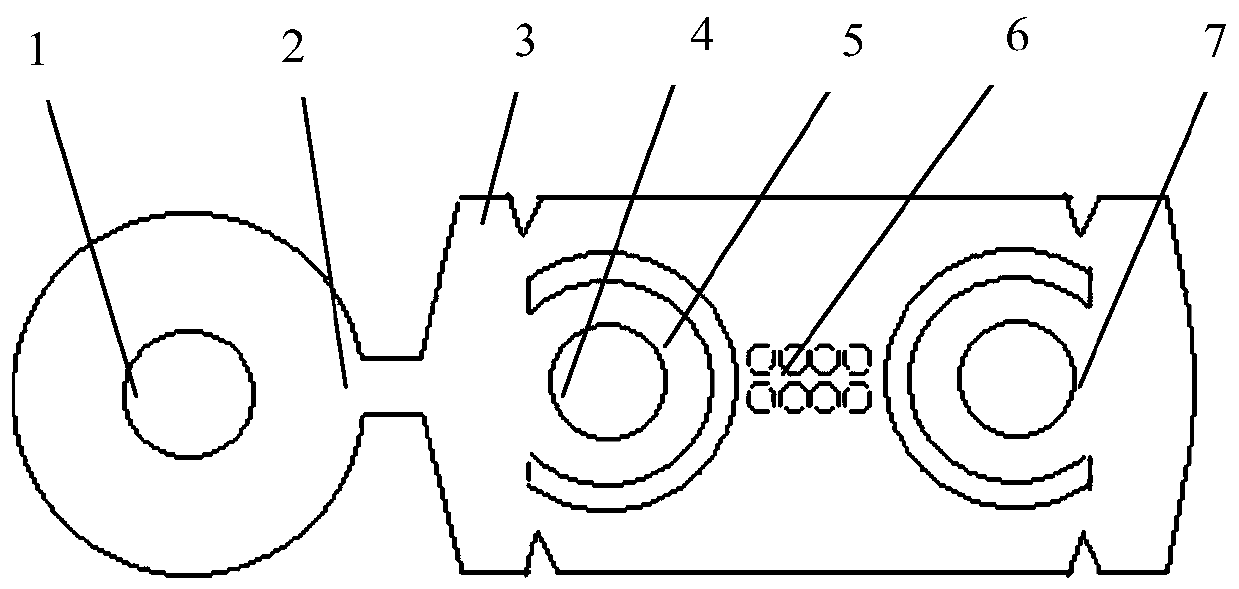

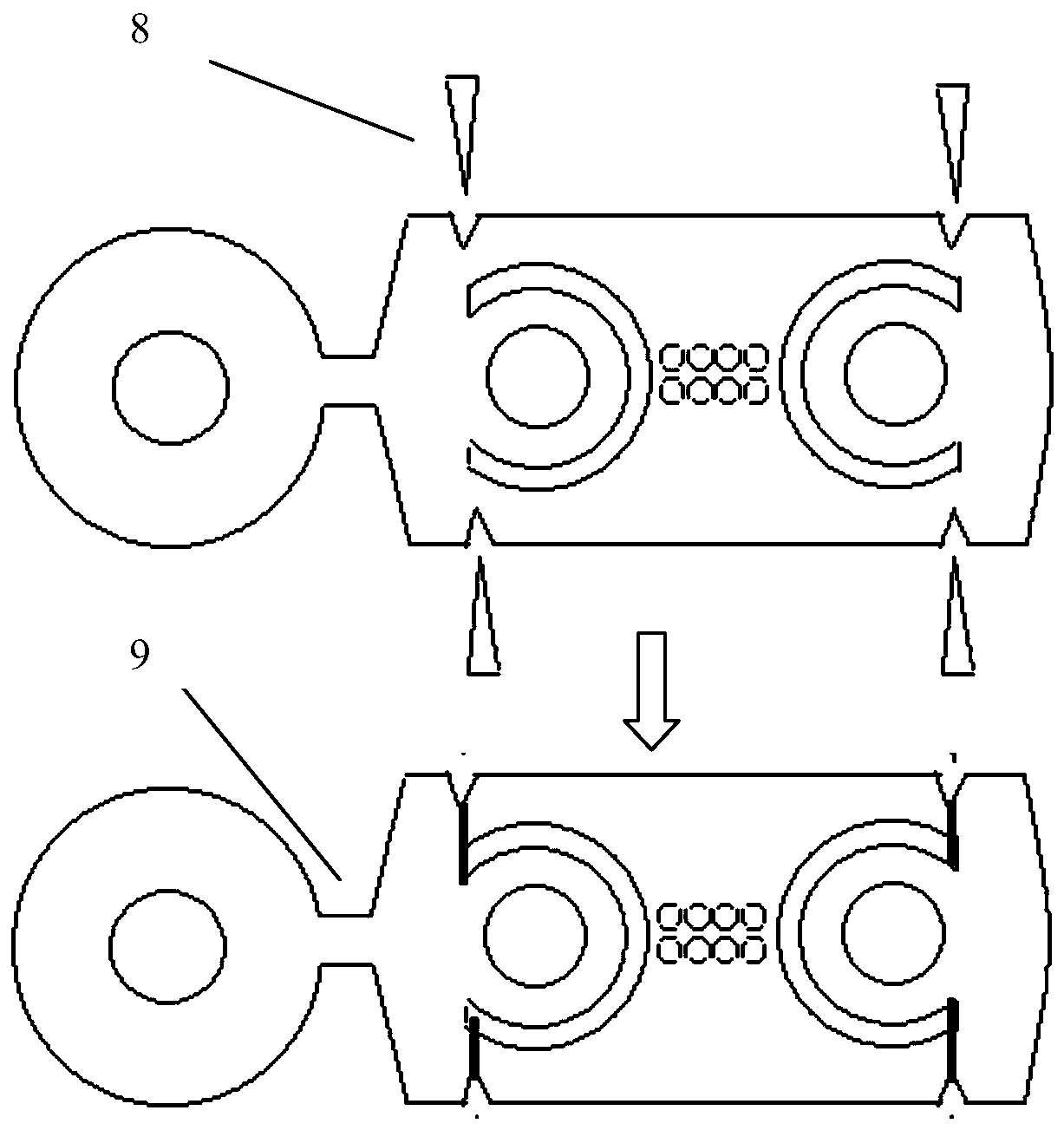

Trench MOSFET with double tube cores and production method of Trench MOSFET

ActiveCN105206606AReduce areaLarge number of coresTransistorSolid-state devicesDouble tubeTrench mosfet

The invention provides a Trench MOSFET with double tube cores and a production method of the Trench MOSFET. The Trench MOSFET comprises an N+ substrate layer, wherein an N- epilayer is arranged on the N+ substrate layer; a first P-body layer is arranged at the left upper part of the N- epilayer; a second P-body layer is arranged at the right upper part of the N- epilayer; the continuous N- epilayer is arranged between the first P-body layer and the second P-body layer; a first Trench groove is formed in the first P-body layer; a second Trench groove is formed in the second P-body layer; the first Trench groove penetrates through the first P-body layer; the second Trench groove penetrates through the second P-body layer; Poly structures are arranged in the first Trench groove and the second Trench groove. According to the invention, the independent Ring structure of two MOSFETs are combined into one Ring structure, so that under the premise that the performance of the product is not impacted, the area of a single MOS is reduced, the effective tube core number of a single MOSFET is increased, and the cost is reduced.

Owner:FUJIAN FUXIN ELECTRONICS TECH CO LTD

Double-tube-core Trench MOSFET and processing method thereof

ActiveCN105206608AReduce areaIncrease the number of effective diesTransistorSemiconductor/solid-state device manufacturingOxide semiconductorTrench mosfet

The invention provides a double-tube-core Trench MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) and a processing method thereof. The double-tube-core Trench MOSFET comprises an N+substrate layer, wherein an N-epitaxial layer is arranged on the N+substrate layer; P-body layers are respectively arranged in the middle and on the two sides of the N-epitaxial layer; a first Trench and a second Trench are respectively arranged on the left side and the right side of each P-body layer; discontinuous P-body layers are arranged between the first Trenches and the second Trenches; the first Trenches and the second Trenches run through the P-body layers; Poly structures are arranged in the first Trenches and the second Trenches; first Drain zones are arranged at the upper parts of P-body layers on the left sides of the first Trenches. According to the invention, independent Ring structures of the two MOSFETs are combined into a Ring structure, so that the advantages of reducing the area of the single MOS, increasing the number of the single effective tube core and reducing the cost are realized on the premise of not influencing the performance of the product.

Owner:FUJIAN FUXIN ELECTRONICS TECH CO LTD

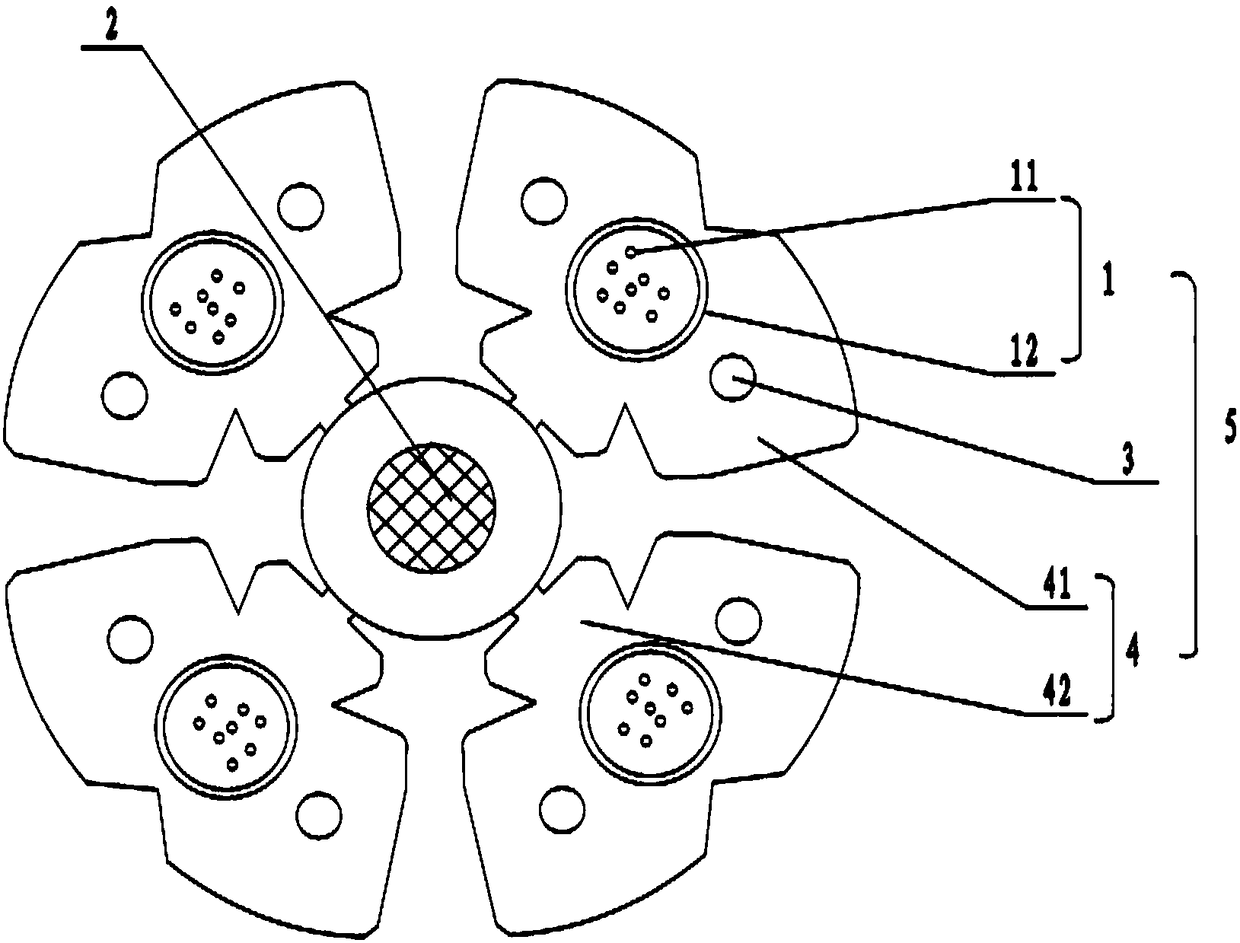

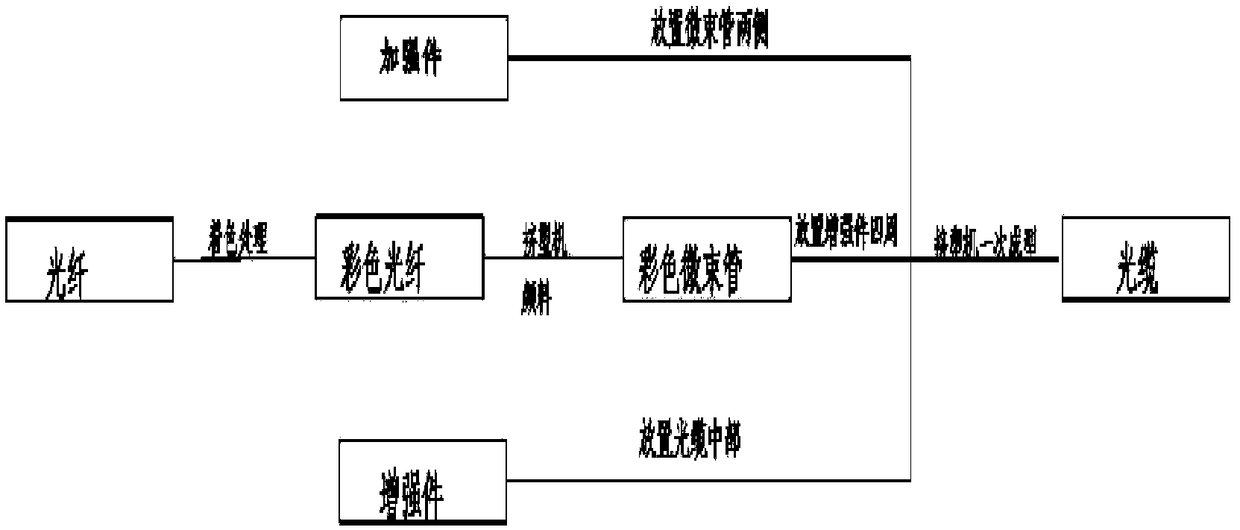

A dry-type water-blocking easily-stripped multi-core micro beam pipe series optical cable

The present invention provides a dry-type water-blocking easily-stripped multi-core micro beam pipe series optical cable including thin-walled micro-tubes, wherein the internal portion of each thin-walled micro-tube is provided with at least two colored optical fibers and a water-blocking yarn. The thin-walled micro-tubes are thermoplastics type flame retardant low smoke halogen-free polyolefin sheathes. The beneficial effects of the present invention are that by wrapping the plurality of colored optical fibers with the thermoplastics type flame retardant low smoke halogen-free polyolefin sheathes, the number of cores of an optical fiber is raised.

Owner:SHENZHEN SDGI OPTICAL NETWORK TECH

High-nodularity nodulizer for nodular cast iron

InactiveCN105925749AImprove absorption rateIncrease the number of graphite coresDistortionBoiling point

The invention discloses a high-nodularity nodulizer for nodular cast iron. The nodulizer is prepared from the following components in percentage by weight: 16% of Mg and Si, 3.0% of Re, 2.1% of Ca, 2.0% of Ba, 0.05% of Bi, 0.09% of Ti, 0.3% of Al, 1.0% of rare earth and Fe in balancing amount. The nodulizer prepared according to the invention adopts rare earth made from yttria, gadolinium oxide, holmium oxide and cerium oxide, so that the nodulizer is greatly enhanced in molten iron purification capacity, nodulizing capacity, nodulizing degeneration resistance and graphite distortion resistance, has a little chilling tendency, can refine a matrix structure, can prevent a resulfurization phenomenon, has high boiling point, can inhibit interference of anti-nodulizing elements, can improve the impact toughness of the nodular cast iron, can also improve the nodularity and the quality of a casting and has the characteristics of energy saving and pollution prevention; the nodulizer can effectively inhibit a nodulizing degeneration phenomenon of the nodular cast iron and meanwhile can accurately control the nodulizing reaction time; and owing to a synergistic effect of the added elements, the strength, hardness and heat resistance of the alloy can be effectively improved, and the nodularity can be greatly improved.

Owner:HEFEI CITY TENVER PRECISION CASTING

Multi-core branched dry type lead-in optical cable and manufacturing method thereof

PendingCN108181694AReduce volumeLarge number of coresFibre mechanical structuresEngineeringOptical fiber cable

The invention discloses a multi-core branched dry type lead-in optical cable. The multi-core branched dry type lead-in optical cable comprises micro bundling tubes, a reinforcing component, strengthening components and an outer sheath; two strengthening components are located at two sides of each micro bundling tube symmetrically; the outer sheath wraps the reinforcing component and the micro bundling tubes; a plurality of branch cables are provided and are distributed to form a circle through enclosing; and the reinforcing component is located at the center of the circle. The invention also discloses the manufacturing method of the multi-core branched dry type lead-in optical cable. The method is simple and convenient. According to the lead-in optical cable of the present invention, a one-trunk and multi-branch structure is formed; and the branch cables can be disassembled according to needs, since the size of the lead-in optical cable is small, and a large number of cores are adopted, and the use of a plurality of wires can be avoided, the layout of the optical cable can be simplified, the problem of disordered wiring can be solved, and safety can be ensured.

Owner:SHANDONG PACIF OPTICS FIBER & CABLE CO LTD

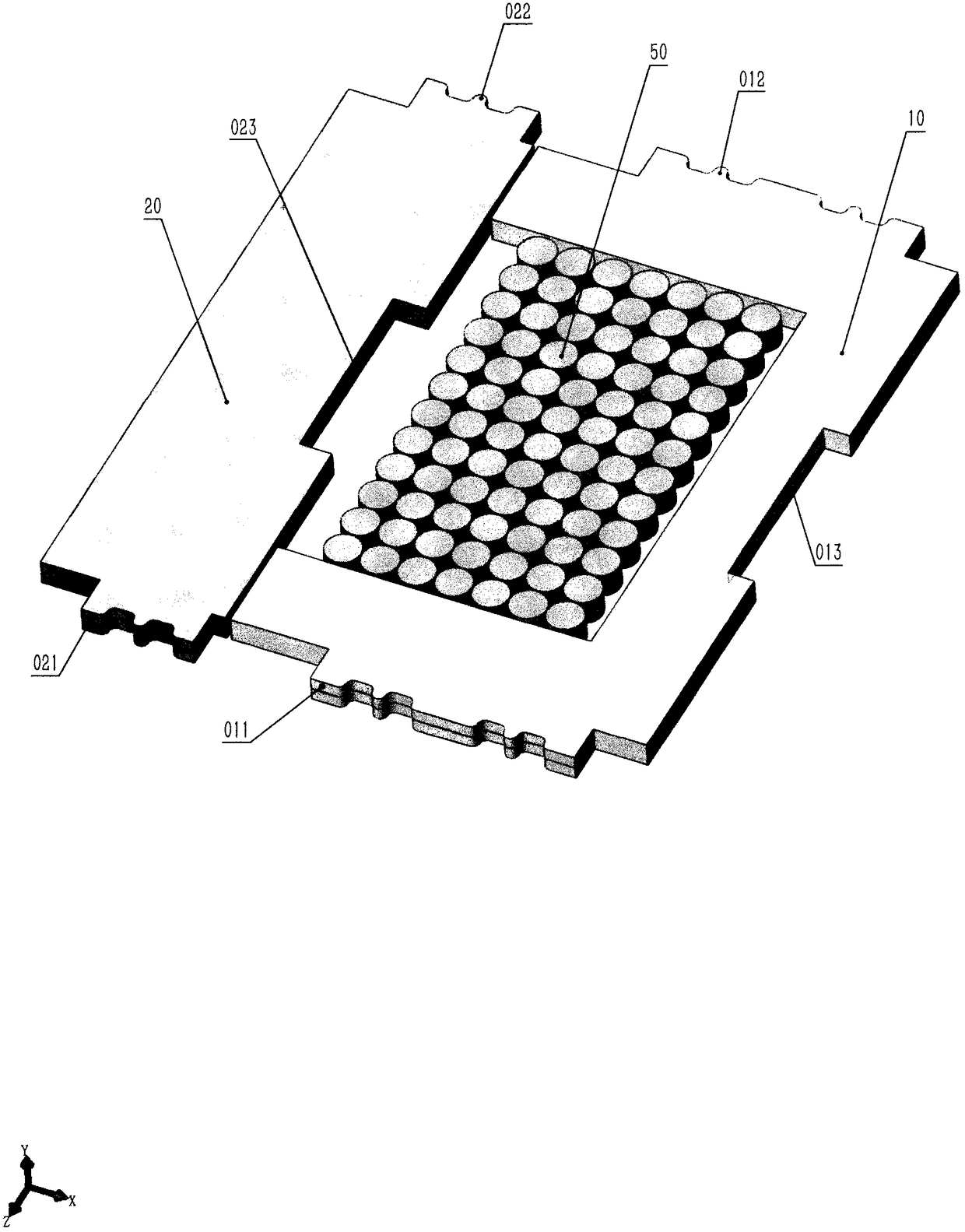

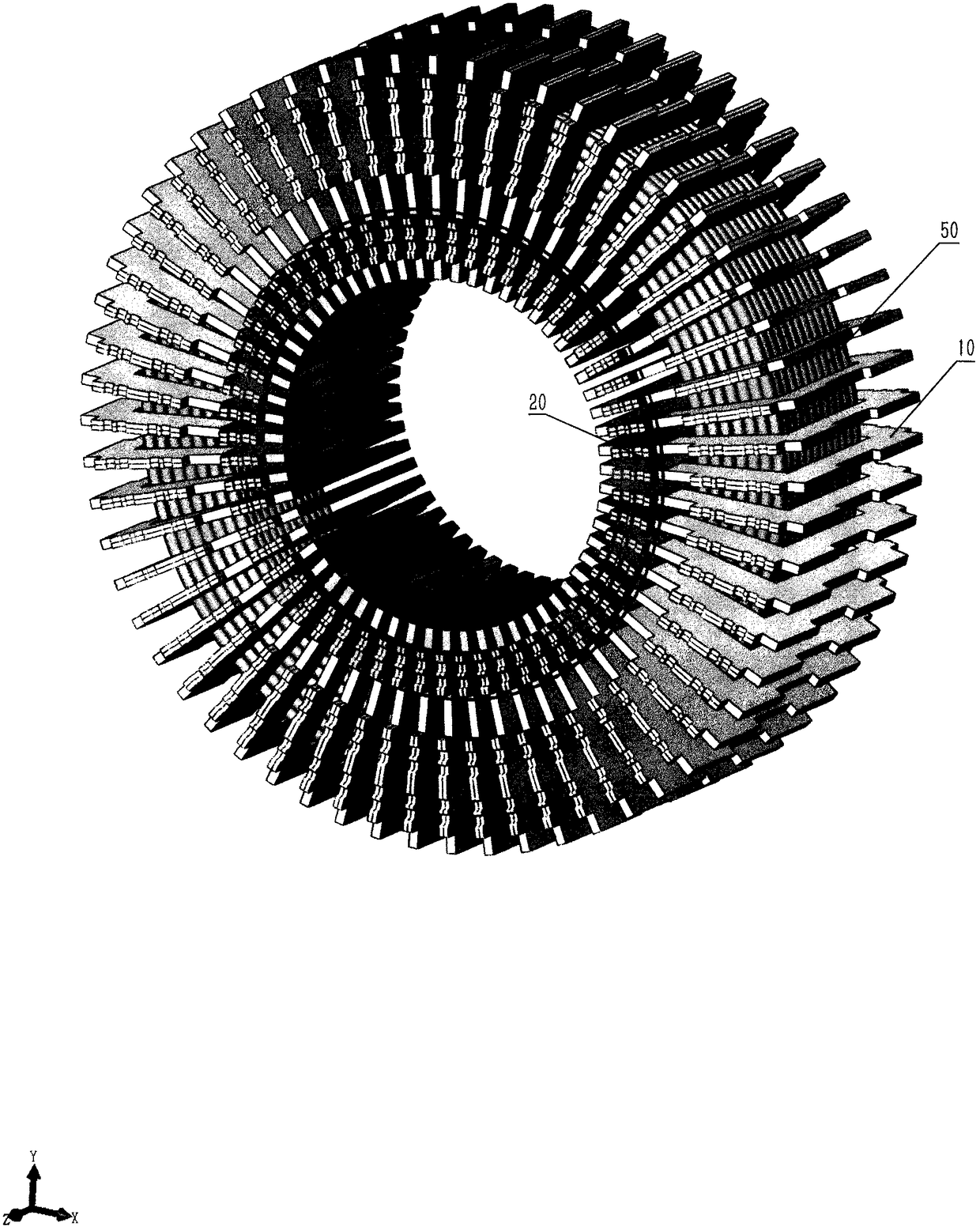

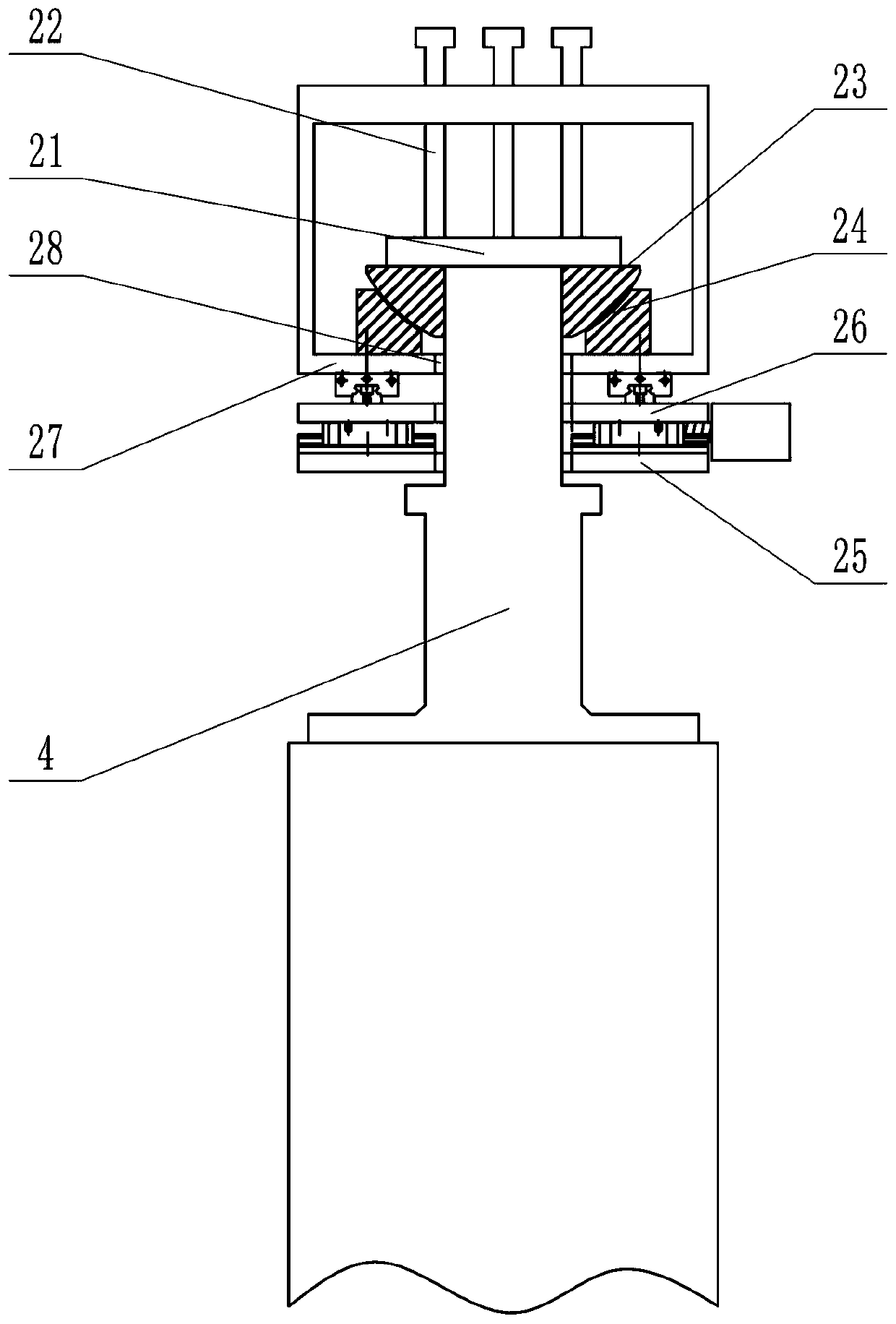

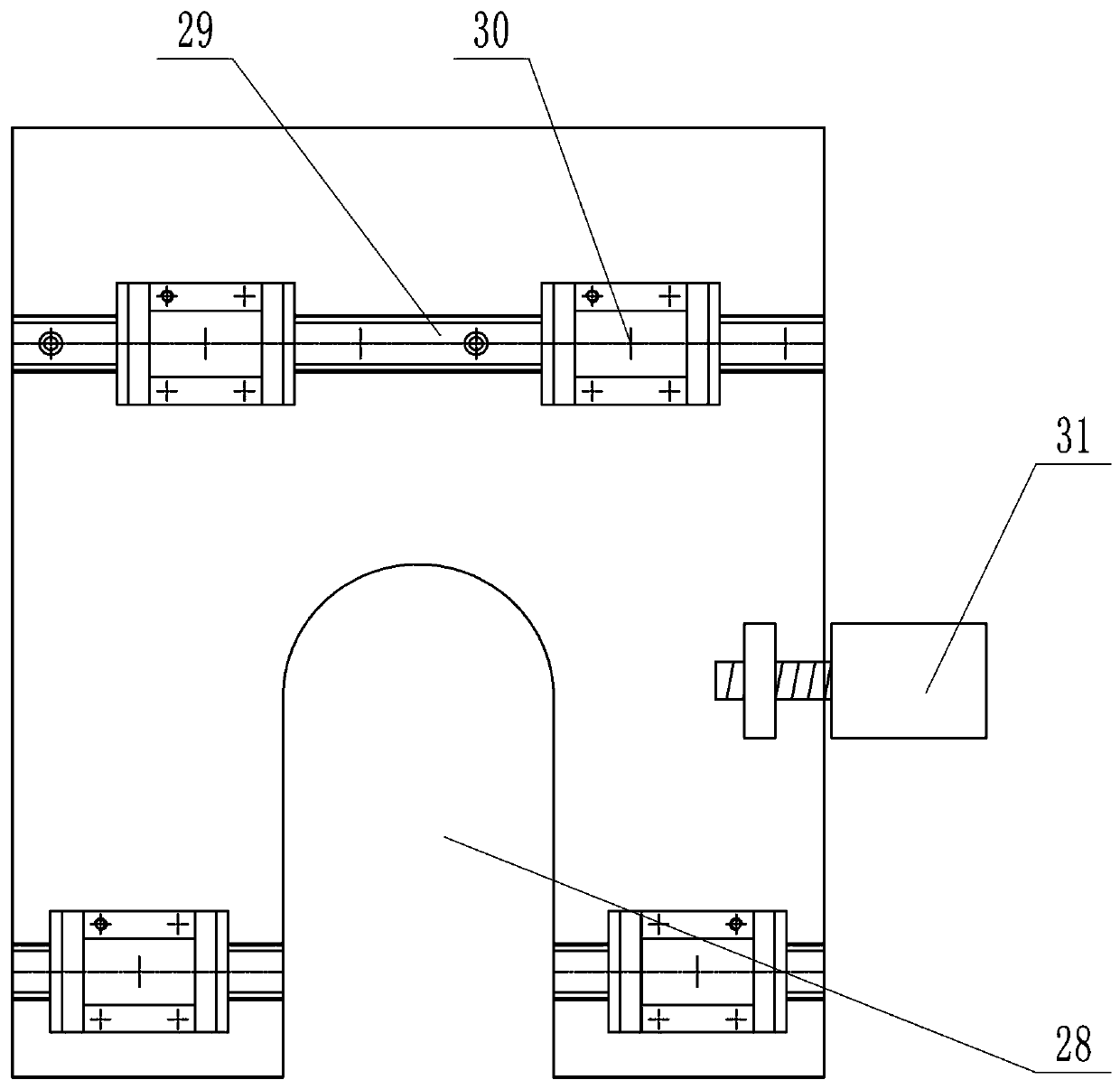

Transverse flux reluctance type low-speed large-torque direct drive synchronous motor

InactiveCN108258866AIncrease diameter sizeIncrease the number of coresMagnetic circuit rotating partsSynchronous motorsTransverse fluxLow speed

The force density of the transverse flux reluctance type low-speed large-torque direct drive synchronous motor is 3-5 times that of the existing radial flux motor. The motor consists of a stator and arotor iron core, a stator and a rotor base body, a phase winding and the like. The stator and the rotor iron core are manufactured by adopting silicon steel sheet punching, rotor iron core punching,cambered surface lamination and argon arc welding to form a stator and a rotor iron core. The stator base body and the rotor base body are axially divided into an m-phase segment, and the pole logarithm of each phase segment is p. The m-phase annular winding is directly wound on the channel of each phase of the stator base, and 2p stator cores are installed in each window segment, distributed circumferentially around the motor axis; 2p rotors are installed in the window hole of each phase of the rotor base, distributed in a circumferential array around the axis of the motor. Each phase rotor core is radially aligned, and each phase stator core is radially offset from each other by a 1 / m pole pitch angle. Under the same rated power, the invention realizes the multi-pole logarithmic design of the motor by reducing the thickness of stator and rotor core and increasing the number of stator cores.

Owner:王新

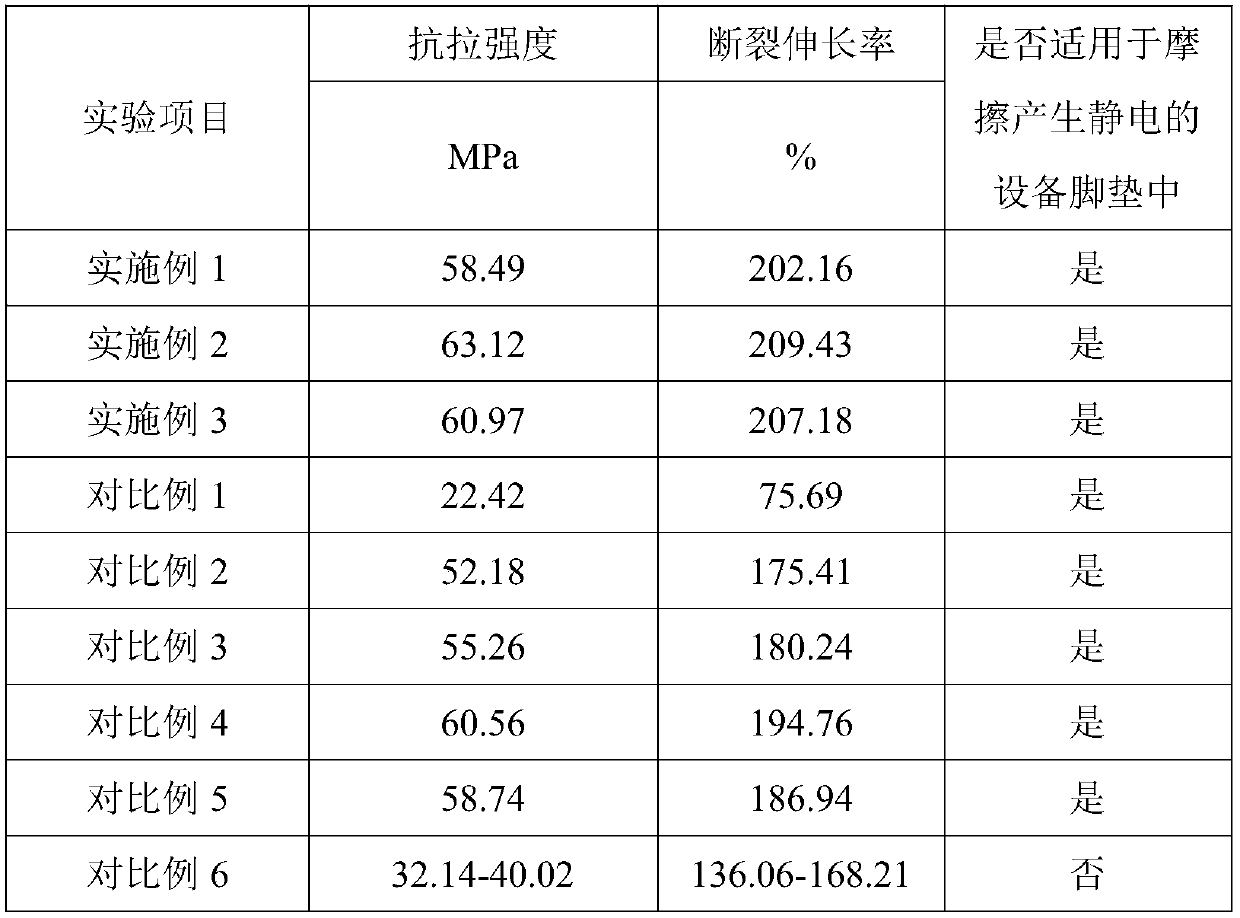

Conductive wear-resistant quakeproof equipment pad material and preparation method thereof

The invention discloses a conductive wear-resistant quakeproof equipment pad material and a preparation method thereof and belongs to the technical field of preparation of pad materials. The conductive wear-resistant quakeproof equipment pad material is made from TPU (thermoplastic polyurethane), stainless steel powder, graphite powder, an antioxidant, a dispersant, nano titanium carbide, nano tungsten carbide, and tungsten powder by: mixing, extruding, cooling, pelletizing and other steps; by using the preparation method herein, tensile strength and elongation of the material can be significantly improved; the material of the invention is widely applicable to precision instrument pads, equipment pads producing static electricity by friction and the like.

Owner:LIUZHOU HAIDA NEW MATERIAL TECH

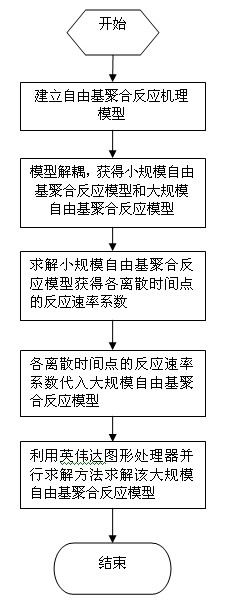

Graphic processor parallel solving method for polymer molecular weight distribution solving

InactiveCN102053820AImprove the speed of solvingIncrease the number of coresConcurrent instruction executionGraphicsSequential method

The invention discloses a graphic processor parallel solving method for polymer molecular weight distribution solving. The method comprises the following steps of: establishing a dynamic analog mechanism model of free radical polymerization reaction to solve polymer molecular weight distribution; decomposing the mechanism model into a small-scale free radical polymerization reaction model and a large-scale free radical polymerization reaction model by a decoupling method; solving the small-scale free radical polymerization reaction model by utilizing a step and order changing backward difference method; and solving the large-scale free radical polymerization reaction model by a parallel sequential method to accelerate the solution of molecular weight distribution calculation by using a graphic processor of the NVIDIA corporation as a calculation platform. Compared with the traditional nonparallel polymer molecular weight distribution solving method, the invention can fully utilize thecharacteristic of high parallel processing ability of the current graphic processor and improve the solving speed of model calculation. The method adopted by the invention has concise and clear principle and is convenient to realize on a computer system with the NVIDIA graphic processor.

Owner:ZHEJIANG UNIV

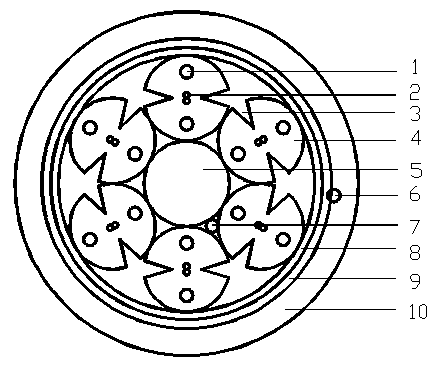

A light insertion force high-speed transmission electrical connector

ActiveCN104409906BSmall insertion forceIncrease differential impedanceIncorrect coupling preventionCoupling contact membersElectrical conductorHigh density

The invention discloses a high-speed electric transmission connector requiring slight plug-pull force. By a contact component composed of a plurality of flexible single needles, 'elastic and elastic' contact mode of contact pairs is realized, and slighter plug-pull force is achieved on the premise of ensuring high reliability in electrical connection. According to the distance among nodes, dielectric constant Epsilon r of a transmission medium is lowered by drilling blind holes in a base and by means of gaps between conductors and holes, in doing so, impedance matching of the signal transmission length direction is realized, and consumption during signal transmission is lowered. In addition, cross talk between differential pairs is reduced by setting earth points between the differential pairs in a staggered manner, and high transmission speed is realized. The high-speed electric transmission connector is widely applicable to manufacture of high-core-number and high-density high-speed transmission connector.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

Optical fiber cable

InactiveCN102759782AHigh tensile strengthHigh compressive strengthFibre mechanical structuresEngineeringWater block

The invention relates to the filed of outdoor optical fiber cable home entrance and indoor FTTH (Fiber To The Home) network cabling. An optical fiber cable comprises a subunit, a central reinforcement piece, an enhancing belt and a sheath, wherein the end face of the subunit is a round on which fan-shaped grooves are symmetrically distributed, the subunit is internally provided with an optical fiber and the reinforcement piece, the subunit is twisted around the central reinforcement piece, the outside of the subunit is provided with a water-blocking tape, the outside of the water-blocking tape is longitudinally provided with an aramid fiber enhancing belt, a sheath protective layer is arranged at the outside of the aramid fiber enhancing belt, and a rip cord is placed between the enhancing belt and the sheath. The optical fiber cable is rational in design, compact in structure, easy to manufacture, low in cost, light in weight, excellent in flexibility, convenient to use and maintain, high in optical fiber density, easy to find and separate the optical fibers, excellent in flame resistance, and capable of being used for indoor multi-purpose cabling and outdoor optical distribution cable.

Owner:宏安集团有限公司

A high-strength antibacterial aluminum alloy for aluminum alloy ladders and its preparation method

ActiveCN107201469BHigh hardnessImprove toughnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to the technical field of aluminum alloy ladder preparation, and particularly relates to high-strength antibacterial aluminum alloy for an aluminum alloy ladder and a preparation method thereof. The aluminum alloy comprises a high-strength aluminum alloy matrix and a micro-arc oxidation film, wherein the micro-arc oxidation film is arranged on the surface of the aluminum alloy matrix, the weight of a hole sealing agent on the micro-arc oxidation film is 0.15 g / cm<2> to 0.90 g / cm<2>, and the hole sealing agent covers at least 92% of micropores in the micro-arc oxidation film. The preparation method comprises the steps of smelting metal, modifying, refining and degassing, pouring and forming and performing quenching treatment, aging treatment, micro-arc oxidation and hole sealing treatment, wherein in the step of modifying, nanometer modificators are uniformly dispersed into liquid alloy obtained by smelting; in the step of refining and degassing, 0.23% to 0.38% of hexachloroethane is added to the modified liquid alloy so as to refine and degas; and the aging treatment is divided into four-stage aging treatment. The aluminum alloy prepared by adopting the preparation method has the characteristics of high hardness, high strength, wear resistance, corrosion resistance, good anti-cracking performance, good antibacterial effect, difficulty in aging and deformation and long service life.

Owner:浙江洋铭实业有限公司

Rare-earth modified aluminum alloy materials and application thereof

The invention discloses rare-earth modified aluminum alloy materials and an application thereof, and belongs to the technical field of aluminum alloy preparation. The rare-earth modified aluminum alloy materials comprise, by mass, 1200-1850 parts of aluminum, 12-19 parts of copper, 5-8 parts of vanadium, 2-6 parts of manganese, 4-8 parts of tin, 1-3 parts of chromium, 20-38 parts of rare earth elements, 10-15 parts of titanium carbide, 8-12 parts of tungsten carbide, 7-9 parts of tungsten silicide, 3-5 parts of tungsten, 15-20 parts of refining agents, and 26-35 parts of grain refiners. The rare-earth modified aluminum alloy materials are prepared through the steps of melting, refining, slagging off, casting and the like. The rare-earth modified aluminum alloy materials are applied to aluminum alloy cables so that the tensile strength, the elongation at break and the corrosion resistance can be remarkably improved.

Owner:广西丰达三维科技有限公司

Novel multi-core neutral optical cable connector

ActiveCN102419464BIncrease radial sizeLarge number of coresCoupling light guidesEngineeringAxial symmetry

The invention relates to an optical cable connector. The technical problem to be solved is to provide a novel multi-core neutral optical cable connector, so that the connector has a compact integral structure, and more than six cores can be arranged easily. The connector is characterized in that: a half of the front end face of a cylindrical substrate is protruded forwards to form a semi-cylindrical guiding platform; a contact pin component mounting hole formed in the semi-cylindrical guiding platform and a contact pin component mounting hole on the end face of the other half of the substrate are distributed in an axial symmetry mode; and when two connectors are spliced, forward-protruded parts can be mutually staggered and spliced with each other to finish splicing. In the optical cable connector, a series of products of a core 2, a core 4, a core 6, a core 8 and the like can be realized without the increase of processing difficulties, and a processing process is relatively simple; in a core body of the substrate, a guiding seat and a contact pin seat body are processed in a separated manner and are assembled with each other, so that the processing difficulties are reduced, and the connector has the advantages of convenience of cleanness and maintenance; and a shell connection structure with a bayonet structure is utilized, so that the connector is easy and convenient to use.

Owner:SHANGHAI FANGAO COMM TECH

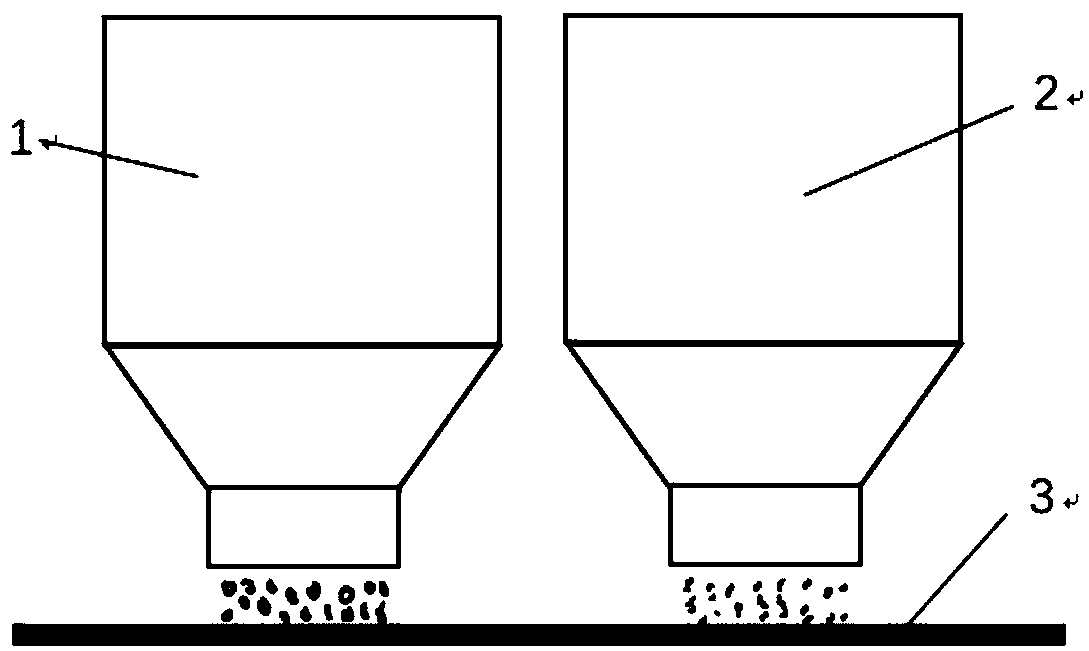

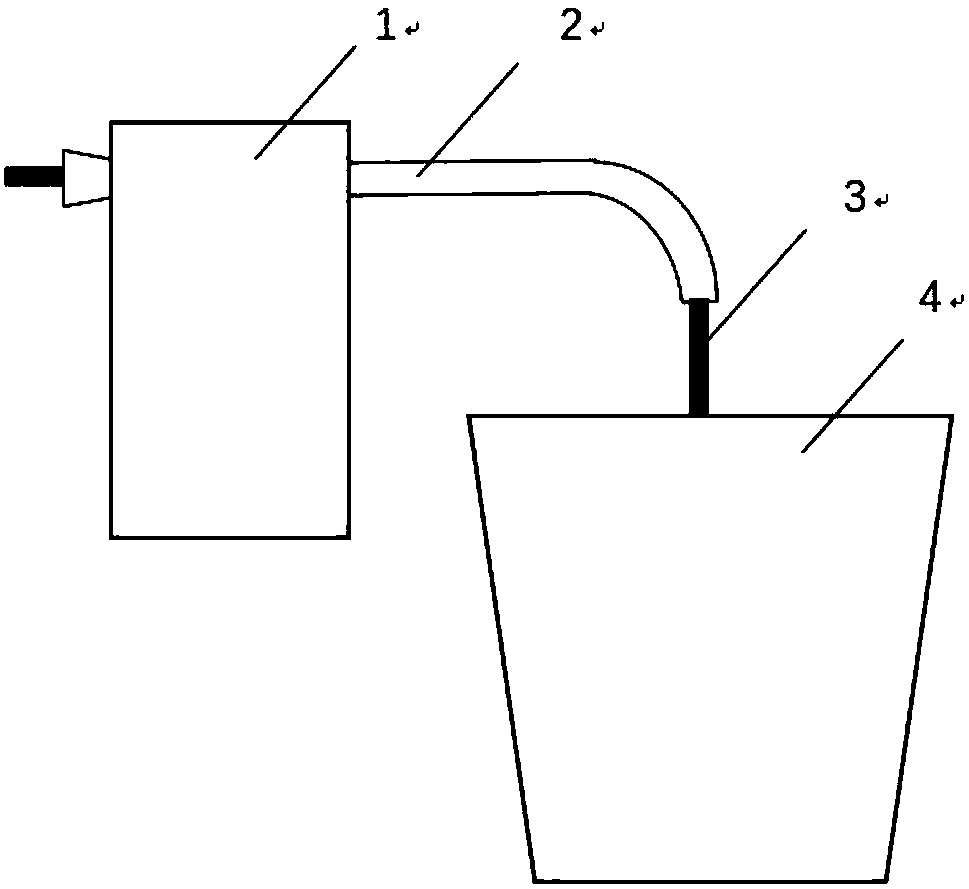

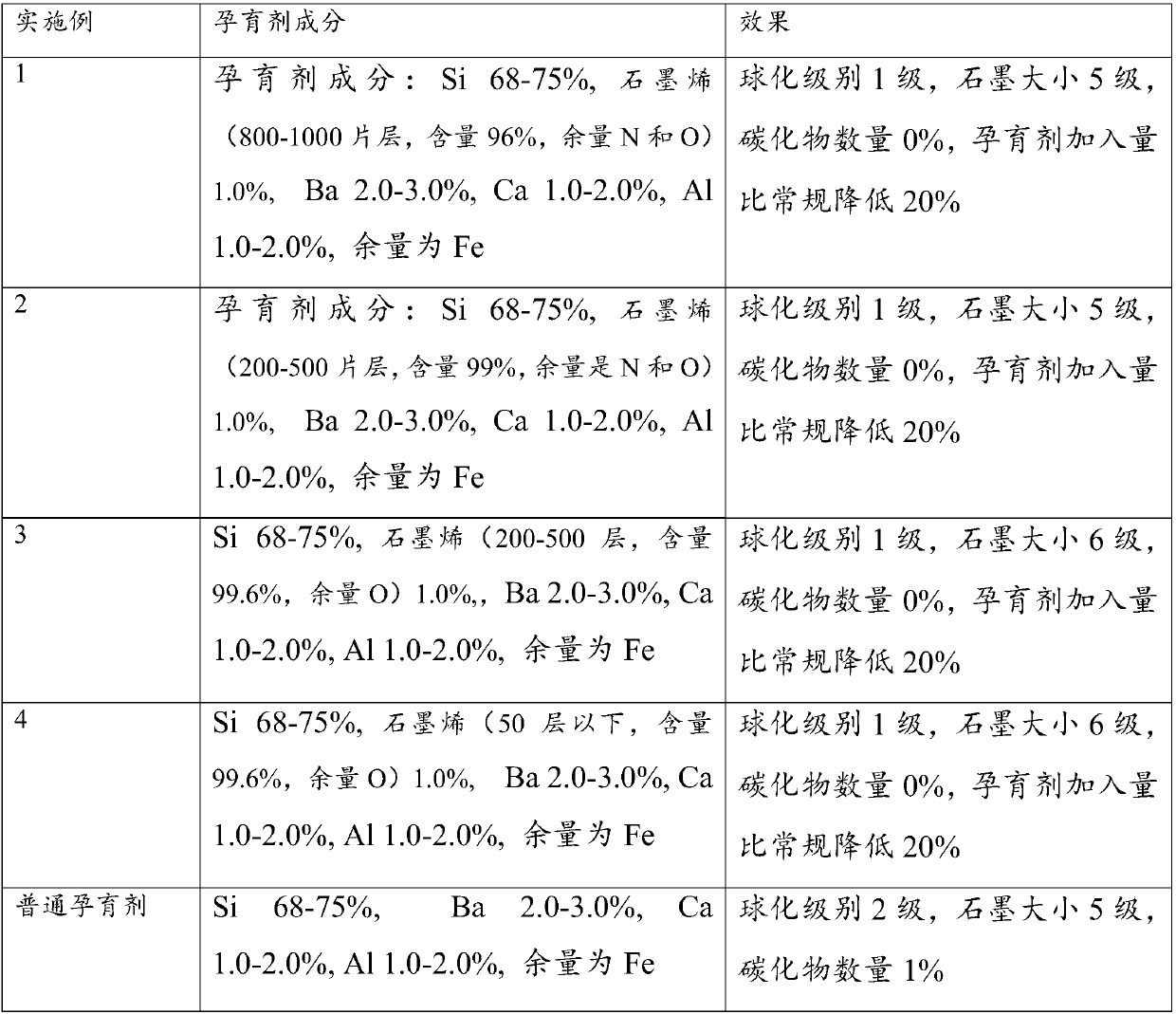

Graphene-containing cast iron inoculant and preparation method and using method thereof

The invention relates to a graphene-containing cast iron inoculant and a preparation method and using method thereof. The invention provides the cast iron inoculant comprising 0.01%-10% by weight of graphene. When used for inoculation, the cast iron inoculant provided by the invention can achieve a better inoculation effect with a smaller addition quantity.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

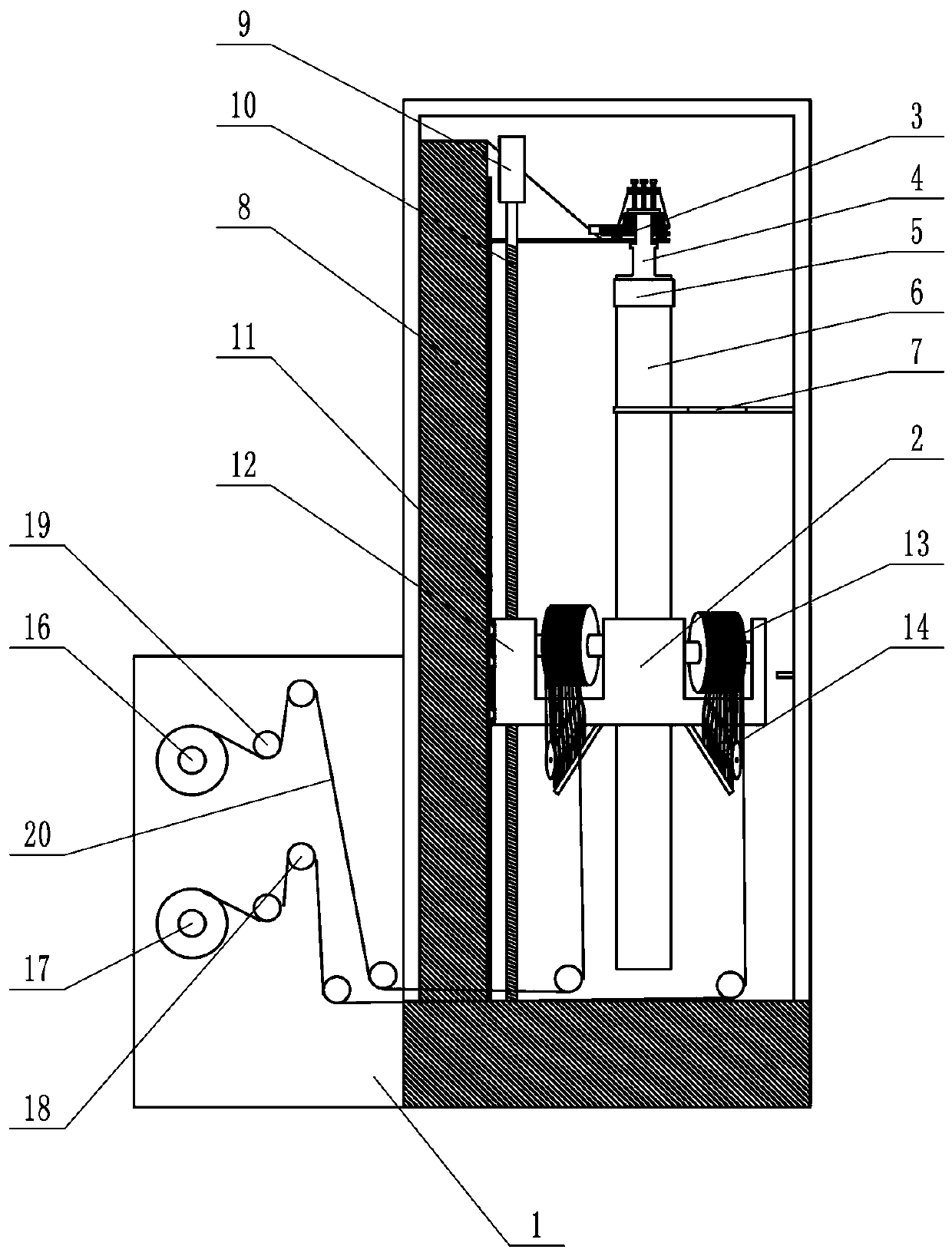

Square silicon core production equipment and manufacturing technology thereof

InactiveCN111136811AImprove efficiencyLarge number of coresFine working devicesLaser rangefinderEngineering

The invention discloses square silicon core production equipment, and relates to the technical field of polycrystalline silicon production. A machine body is included. Four rollers are evenly distributed on the outer edge of the machine body. A silicon bar is hung at the middle position of the machine body. The position, corresponding to the top of the silicon bar, of the machine body is providedwith a bar hanging device. The position, corresponding to the silicon bar, of the bar hanging device is provided with a bar hanging port. The position, corresponding to the bar hanging port, of the machine body is provided with a bar hanging piece. The bar hanging piece comprises a bar hanging head and a bar bonding head which are sequentially connected from top to bottom. The outer diameter of the bar hanging head is matched with the U-shaped bar hanging port. The top of the bar hanging head is provided with a pressing plate. The machine body is movably provided with a plurality of screw jackscrews. The position, corresponding to the upper end face of the bar hanging port, of the bar hanging head is provided with an angle contact joint bearing. The positions, corresponding to the two endsof the two opposite rollers, of the machine body are provided with a tool setting measuring device. The tool setting measuring device comprises four laser distance measuring instruments, the laser distance measuring instruments perpendicular to the silicon bar axial position are arranged on the machine body, tool setting is convenient and fast, the core discharging rate is maximum, and product benefits are increased.

Owner:河南协鑫光伏科技有限公司

Self-supporting type indoor and outdoor easily-branched optical cable and extrusion mold thereof

PendingCN110126231APromote productionGuaranteed normal formationOptical articlesFibre mechanical structuresMechanical propertyOptical fiber cable

The invention discloses a self-supporting type indoor and outdoor easily-branched optical cable and an extrusion mold thereof. The extrusion mold comprises a mold sleeve and a mold core, the mold coreis a disc with a conical protrusion, a pair of symmetrically-distributed mold core and mold sleeve matching rods are arranged on the disc, and the top surface of the conical protrusion is provided with a penetration-in groove of the easily-branched optical cable; the mold sleeve is a cylinder with a conical groove, the center of the cylinder is provided with an optical cable forming groove for containing the easily-branched optical cable, the two sides are provided with mold sleeve positioning holes, and the mold core and the mold sleeve are connected by enabling the mold core and mold sleevematching rods to penetrate into the mold sleeve positioning holes; and a protective sleeve material extrusion channel is arranged between the mold sleeve and the mold core. The easily-branched optical cable is stripped from outer arc surfaces of upper and lower V-shaped grooves and C-shaped gaps to the upper and lower ends of a tight-buffered optical fiber, and the tight-buffered optical fiber ofthe easy-branched optical cable can be separated from an outer protective sleeve. The optical cable has the advantages of being small in weight, easy to branch, large in core number and excellent inmechanical property.

Owner:FURUKAWA ELECTRIC XIAN OPTICAL COMM

Thin-wall adhesion-facilitating polar polypropylene material and preparation method thereof

The invention discloses a thin-wall adhesion-facilitating polar polypropylene material, and belongs to the technical field of preparation of polypropylene composite materials. The thin-wall adhesion-facilitating polar polypropylene material is prepared from the following raw materials: PP (polypropylene), POE (polyene elastomer), maleic anhydride-grafted PP, nano calcium carbonate, CPE (chlorinated polyethylene), MBS (methyl methacrylate), barium sulfate, a rare earth coupling agent, an antioxidant, a dispersant, nano titanium carbide, nano tungsten carbide, tungsten silicide and tungsten powder; the polypropylene material is prepared by steps of mixing, plasticization, water-cooled bracing, granulation and the like. By the adoption of the process disclosed by the invention, the tensile strength, the elongation at break and the like of the thin-wall adhesion-facilitating polar polypropylene material can be obviously improved.

Owner:LIUZHOU HAIDA NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com