LRM (Line replaceable module) low-frequency high-density surface mount connector plug

A connector plug and surface mount technology, which is applied in the direction of connection, fixed connection, and parts of the connection device, can solve the problems of impracticability and increased difficulty of tail end bending, and achieve simple structure and increased pattern density. and the effect of the number of cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

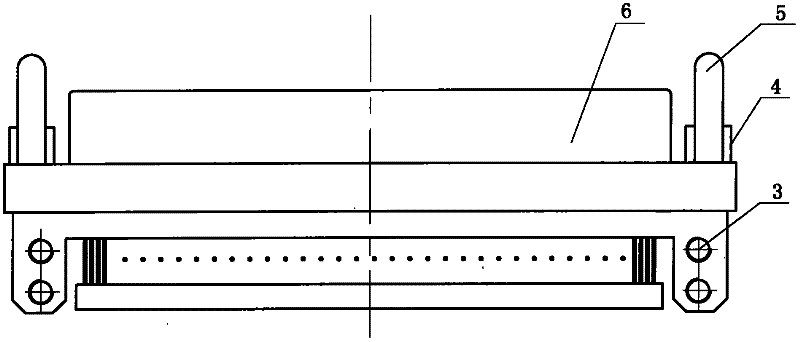

[0030] As shown in Figure 1: the LRM connector plug of the present invention is mainly composed of shell A1, shell B2, locking screw 3, guide pin 4, coding piece 5 and low-frequency high-density surface mount base assembly 6; low-frequency high-density The flange of the surface mount base assembly 6 is engaged with the groove in the shell A1 and the shell A2, and the shell A1 and the shell A2 are fixed together with the screws 3, so that the connector is fixed; the guide pin 5 is screwed into the In the corresponding threaded hole of the housing A1, the coding piece 4 is interference-fitted in the groove of the housing B to prevent mis-insertion.

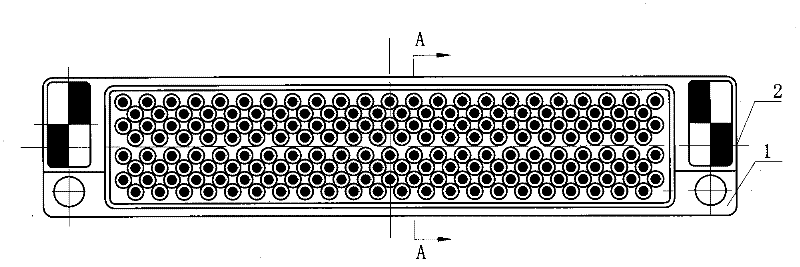

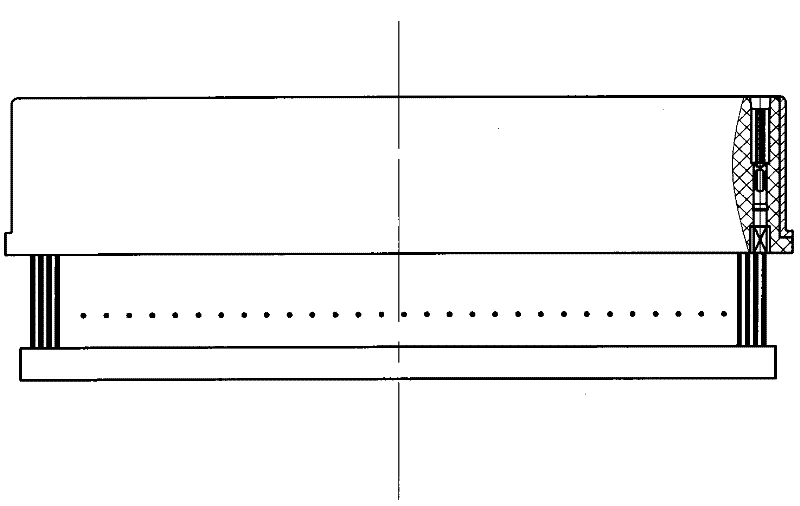

[0031] Such as figure 2 Shown: the LRM connector plug low-frequency high-density surface mount base assembly of the present invention consists of a base 6.1, a shielding cover 6.2, a fixing bar 6.3, a pin assembly A6.4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com