Optical fiber cable

An optical fiber cable, optical fiber technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of large mechanical tension and crushing force, loose structure in the cable, disordered optical fiber order, etc., and achieves increased tensile strength, compact structure, and core count big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

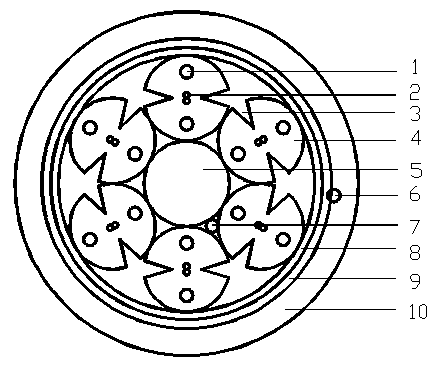

[0013] Depend on figure 1 It can be seen that an optical fiber cable includes a subunit 4, a central strength member 5, an increase belt 9, and an outer sheath 10. The end face of the subunit 4 is circular with fan-shaped grooves 3 symmetrically distributed on the circumference. The subunit There are optical fibers 2 and strength members 1 inside, subunits 4 are twisted around the central strength member 5, and a water-blocking tape 8 is provided on the outside, and an aramid fiber reinforcement tape 9 is arranged longitudinally on the outside of the water-blocking tape 8, and the outside of the reinforcement tape 9 A protective layer of outer sheath 10 is provided, and a tearing rope 6 is placed between the reinforcement band 9 and the outer sheath 10, which is beneficial for stripping the outer sheath of the optical cable during construction.

[0014] In the subunit 4, the optical fiber is placed in the center of the circular end face, and there are two non-metallic strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com