A dry-type water-blocking easily-stripped multi-core micro beam pipe series optical cable

A micro-bundle tube and water-blocking technology, which is applied in the field of optical cables, can solve the problems of difficult formation of optical cables, fewer cores, and low integration of optical cables, and achieve the effect of increasing the number of cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

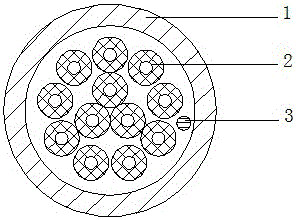

[0013] Such as figure 1 As shown, a dry-type water-blocking and easy-to-peel multi-core micro-bundle tube series optical cable includes a thin-walled micro-tube 1, and at least two colored optical fibers 2 and a water-blocking yarn 3 are arranged in the thin-walled micro-tube 1. The thin-walled micro-tube Pipe 1 is a thermoplastic flame-retardant low-smoke halogen-free polyolefin sheath.

[0014] Such as figure 1 As shown, the colored optical fiber 2 is an optical fiber whose outer surface is coated with color.

[0015] Such as figure 1 As shown, the water-blocking yarn 3 is a fully dry water-blocking yarn with low linear density.

[0016] Such as figure 1 As shown, there are 12 or 32 colored optical fibers 2 .

[0017] Such as figure 1 As shown, the thickness of the thin-walled microtube 1 is 0.15 mm.

[0018] Such as figure 1 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com